Manipulator used for disassembling and assembling radioactive source standard liquid target

A standard liquid, manipulator technology, applied in manipulators, metal processing, metal processing equipment, etc., can solve the problems of radiation hazards, insufficient positioning accuracy, and reduced operating efficiency for source-changing technicians, achieving a wide range of applications, responsiveness, and work. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

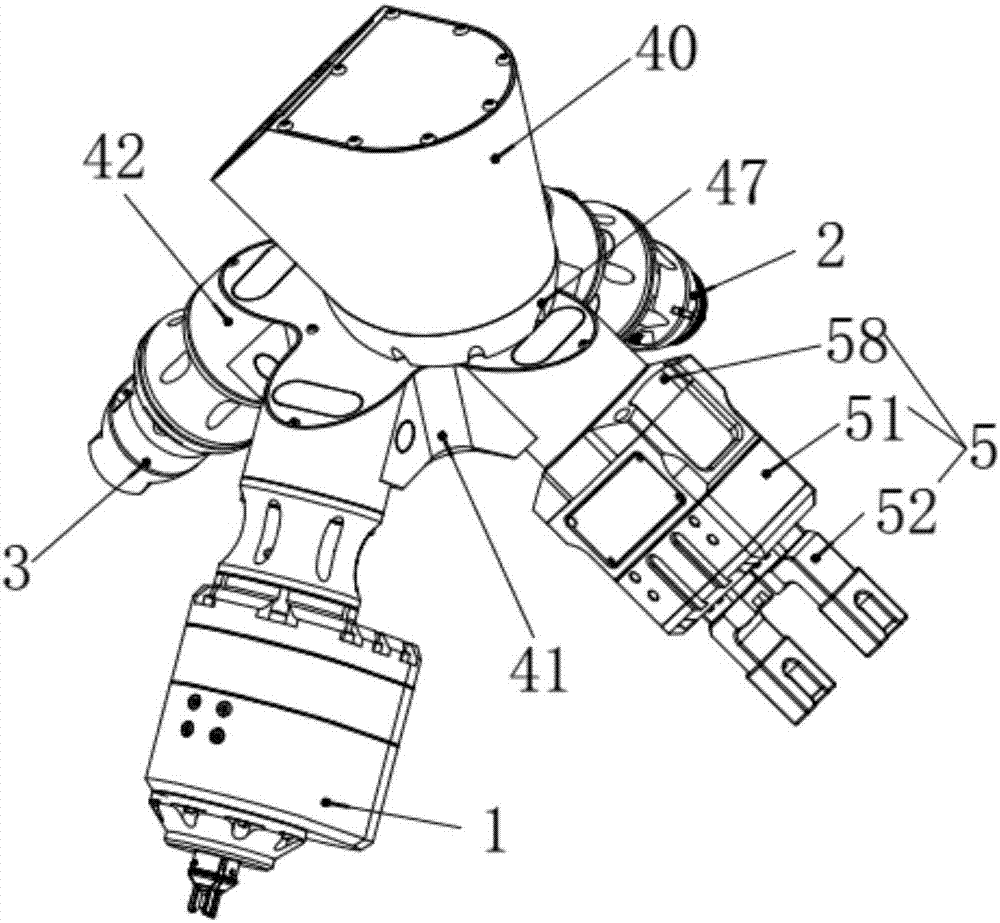

[0046] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-Figure 23 ,

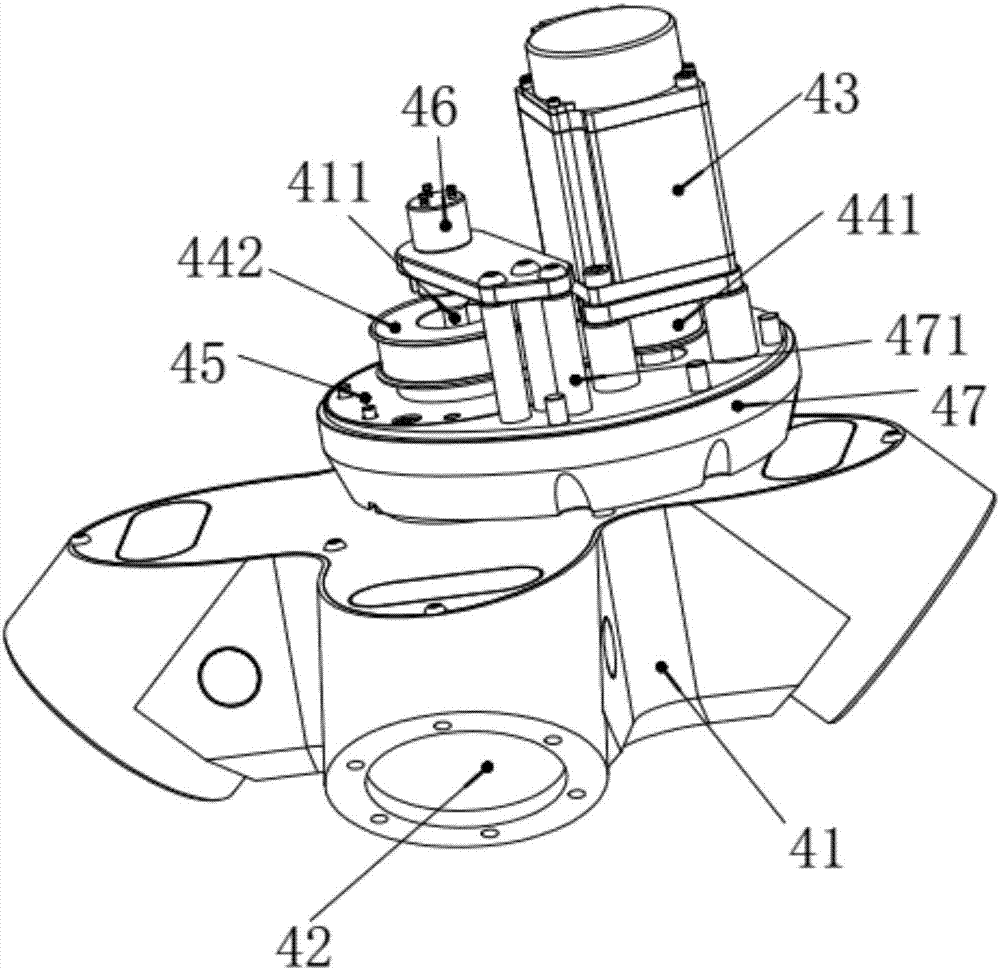

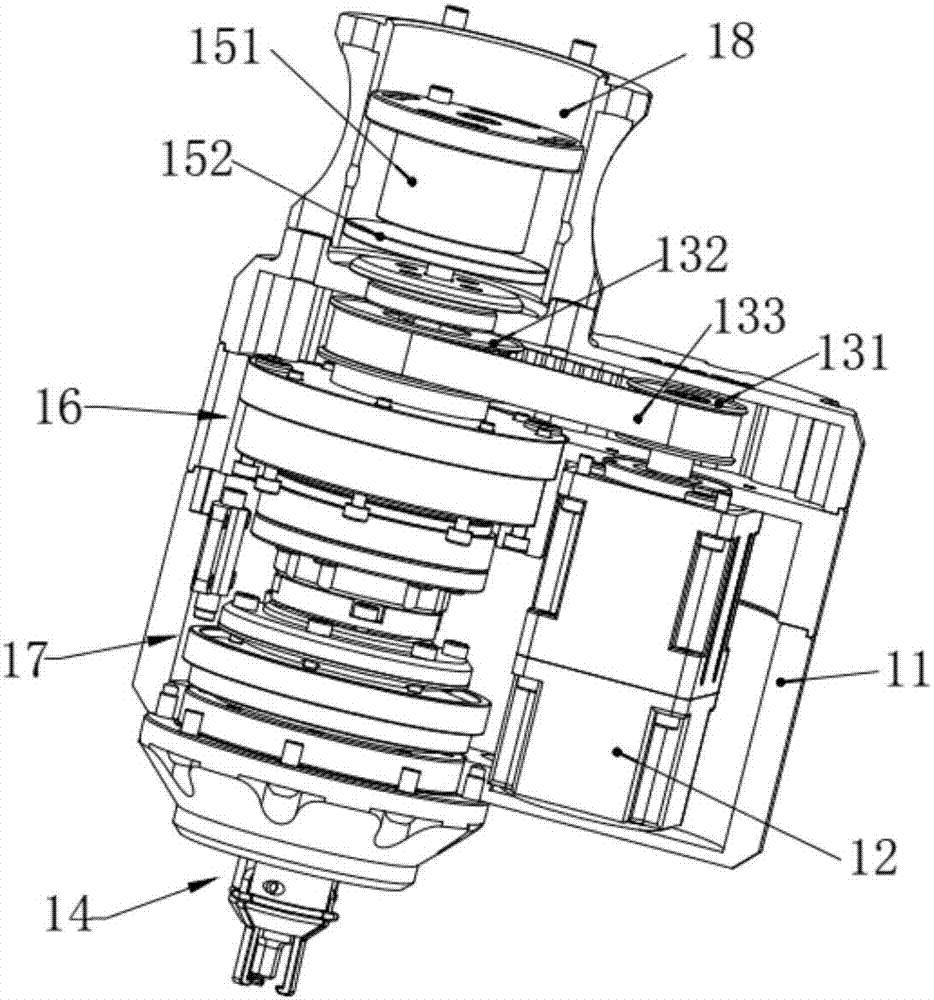

[0047] A manipulator for disassembling standard liquid targets of radioactive sources, including a rotating mechanism connected to the main body of the robot. The rotating mechanism is provided with a rotating part 41, and several rotating heads 42 are formed on the rotating part 41. The rotating head 42 Screw and bolt dismantling manipulator 1, workpiece clamping manipulator 5, sealing ring drawing manipulator 3 and suction cup manipulator 2 are respectively installed on it; the inside of the rotating mechanism is provided with a control mechanism 43, a transmission mechanism, a deceleration mechanism 45 and an angle sensor 46, an angle sensor 46 is connected to the rotating part 41 .

[0048] Described rotating mechanism comprises casing 40 and fixed base 47, and fixed base 47 is fixedly installed on the housing 40 by s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com