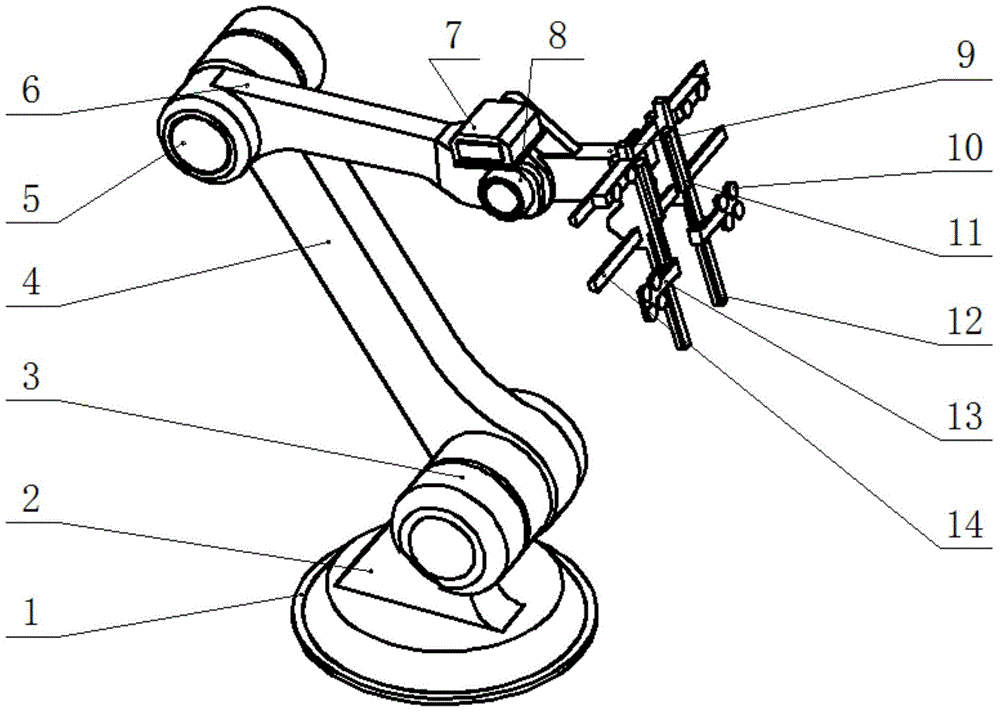

Glass carrying and stacking manipulator

A manipulator and palletizing technology, applied in the field of glass handling and palletizing manipulators, can solve the problems of unsuitable glass for fragile products, difficult manual operation, rough handling and palletizing action form, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

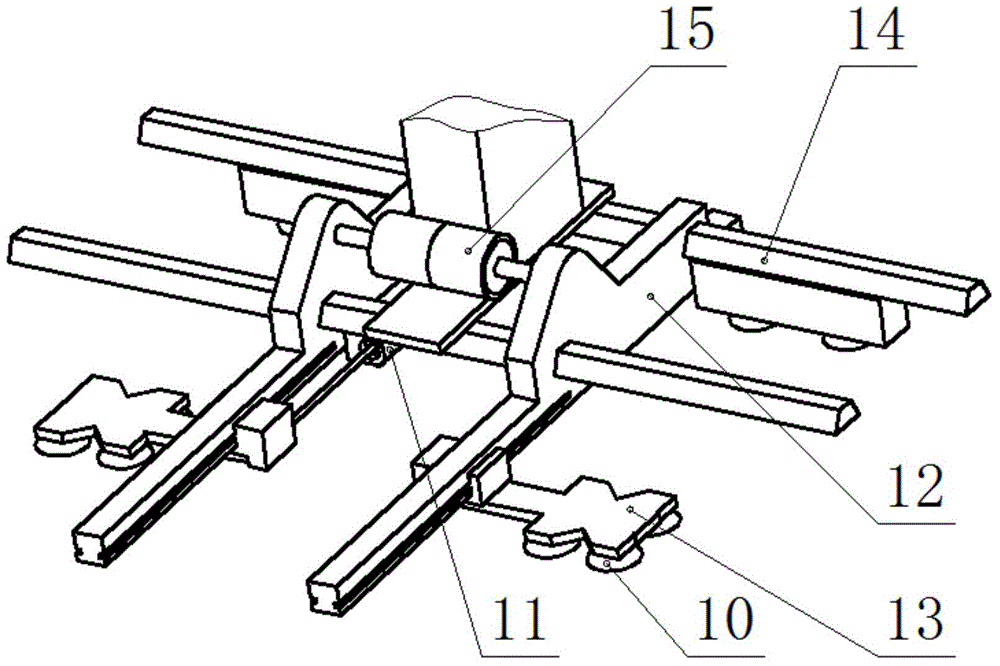

[0009] As shown in the figure, a glass handling and palletizing manipulator is composed of a fixed base 1, a rotating pedestal 2, a hydraulic motor I3, a large boom 4, a hydraulic motor II5, a small boom 6, a vacuum pump 7, a servo motor 8, The end boom 9, the suction cup 10, the longitudinal adjustment cylinder 11, the adjustment slide rail 12, the suction cup sliding frame 13, the fixed slide rail 14, and the horizontal adjustment cylinder 15 are characterized in that: the fixed base 1 and the rotating pedestal 2 pass through the gear teeth The rings are assembled together and can be rotated. The large boom 4 realizes a relatively rotatable hinge through the hydraulic motor I3 and the rotating pedestal 2. The small boom 6 forms a relatively rotatable hinge with the big boom 4 through the hydraulic motor II5. The end boom 9 It is hinged with the small moving arm 6 and driven by a servo motor 8 to rotate, and the fixed slide rail 14 is fixedly connected to the end surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com