Servo wire feeding device for automatic welding robot

An automatic welding and wire feeding device technology, which is applied in welding equipment, welding equipment, auxiliary equipment, etc., can solve the problems of affecting the work of motors and robots, excessive dust, and debris peeled off from welding wire, etc., and achieves compact structure and simple overall structure , Good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below, but the present invention is not limited to the following examples.

[0034] The servo wire feeding method currently uses angle encoder feedback wire feeding and linear sensing wire feeding. The present invention utilizes a linear buffer device to achieve a solution for the synchronization of the wire movement of the welding torch part pushing and pulling mechanism and the wire feeding mechanism.

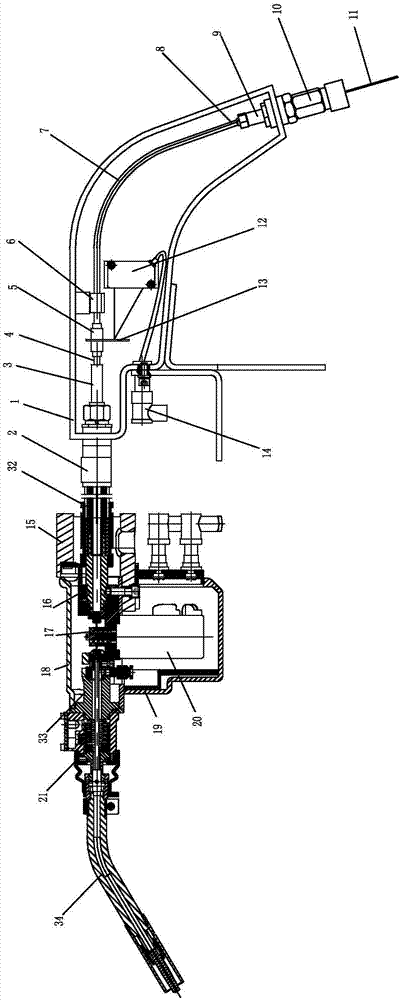

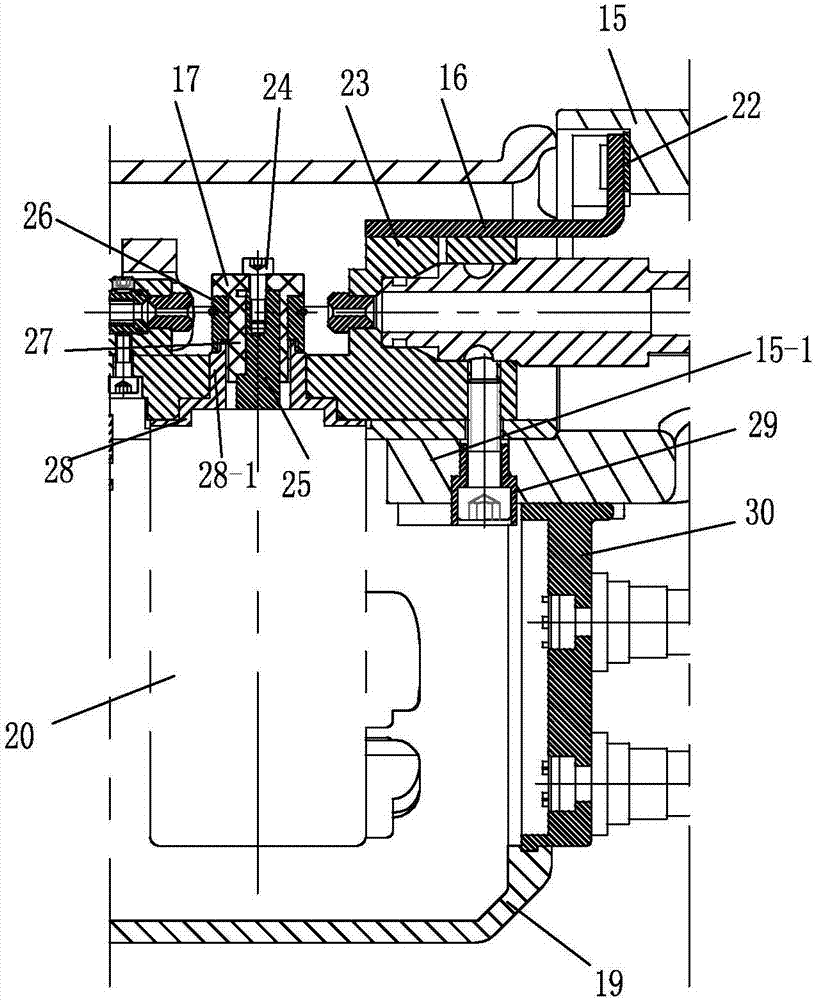

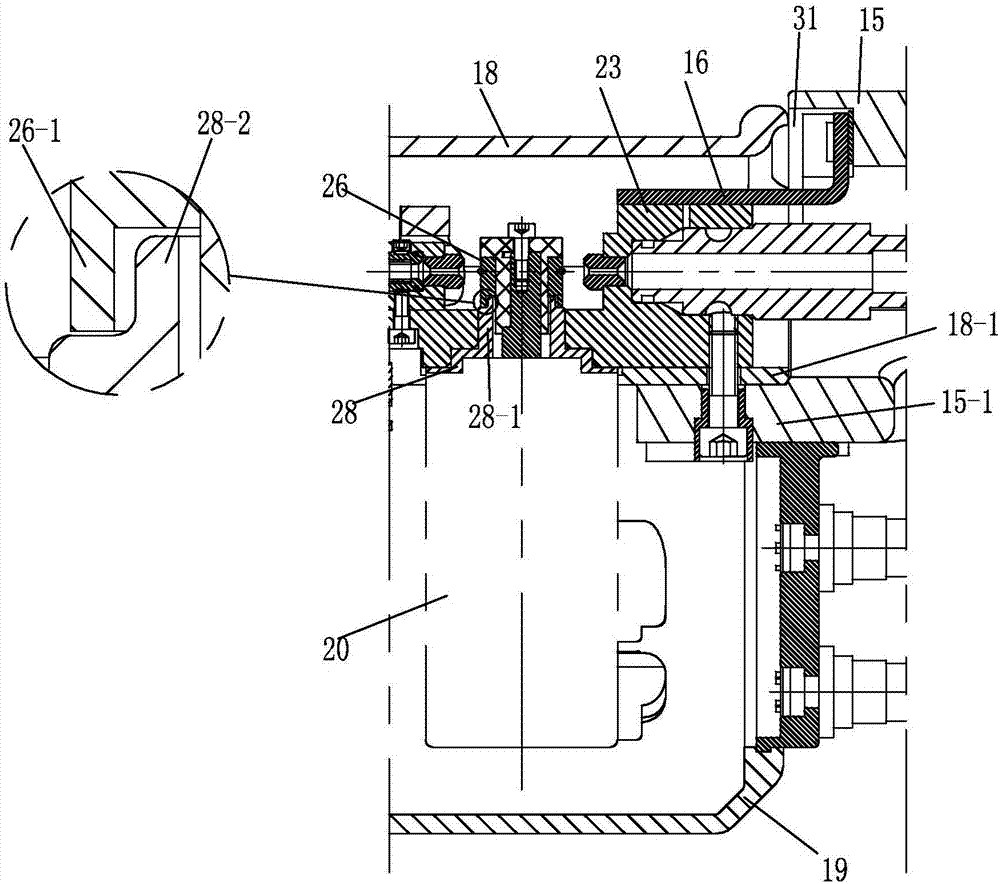

[0035] Such as Figure 1 to Figure 5 As shown, the servo wire feeding device of the present invention includes a servo wire feeding torch body and a linear buffer of the servo wire feeding device connected to its tail end through a conductive cable.

[0036] The servo wire-feeding welding torch body includes a barrel assembly 34 installed on the front side of the servo wire-feeding welding torch, and an anti-collision sensing device 21. The interior of the servo wire-feeding welding torch body passes through a transition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com