Single servo power tool rest

A technology of power tool holder and tool holder, which is applied in metal processing mechanical parts, precision positioning equipment, metal processing equipment and other directions to achieve the effect of improving transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

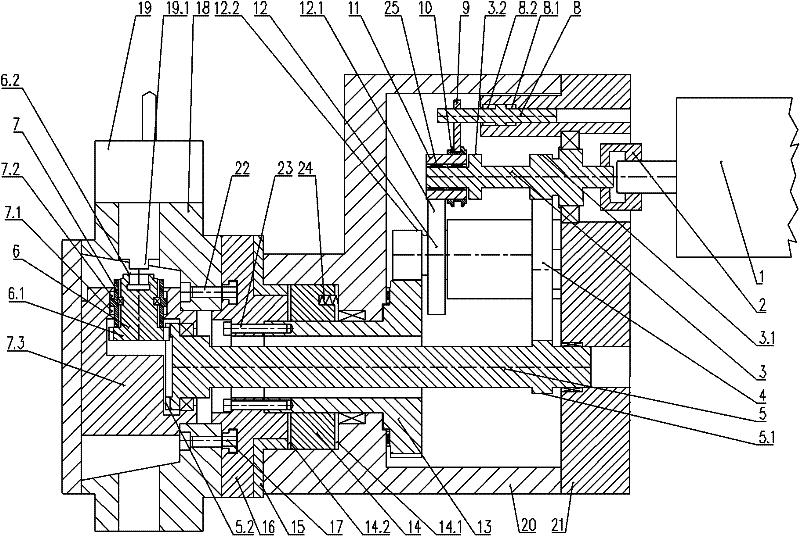

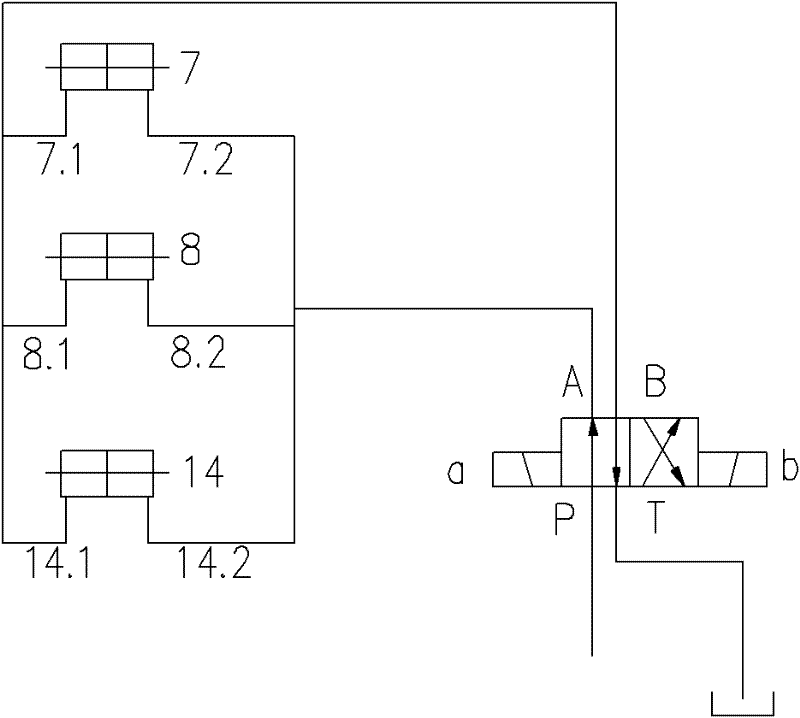

[0033] Such as figure 1 As shown, the single servo power tool post of the present invention mainly includes a cutter head 18 for installing a tool holder 19, a tool holder box 20, a rear seat cover 21, a cutter head indexing mechanism, a power tool driving mechanism, and a hydraulic transmission and control mechanism , the specific structure is as follows:

[0034] Install the rear seat cover 21 at one end of the tool rest case 20, and install the fixed toothed disc 15 and the movable toothed disc 16 at the other end of the tool rest case 20 successively, and one end of the fixed toothed disc 15 and the movable toothed disc 16 extends to the tool rest case In the body 20, the fixed toothed disc 15 is fixed on the knife rest box 20, the movable toothed disc 16 can rotate in the tool rest box 20, and the outer end of the movable toothed disc 16 is connected with the cutter head 18;

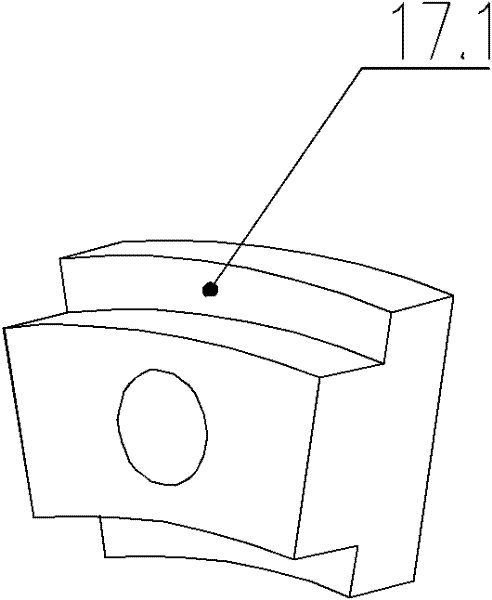

[0035] The first rotating shaft 3, the second rotating shaft 5, and the third rotating shaft 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com