Five-axis linkage laser cutter

A laser cutting, five-axis linkage technology, used in laser welding equipment, welding/cutting auxiliary equipment, auxiliary devices, etc., can solve the problem of difficulty in determining the turning angle of arc-shaped or spherical workpieces, inability to process the bottom surface of the workpiece, affecting processing accuracy, etc. problems, to increase stability and accuracy, reduce weight, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to describe in detail the technical content, structural features, achieved objectives and effects of the present invention, the following is a detailed description in conjunction with the embodiments and accompanying drawings.

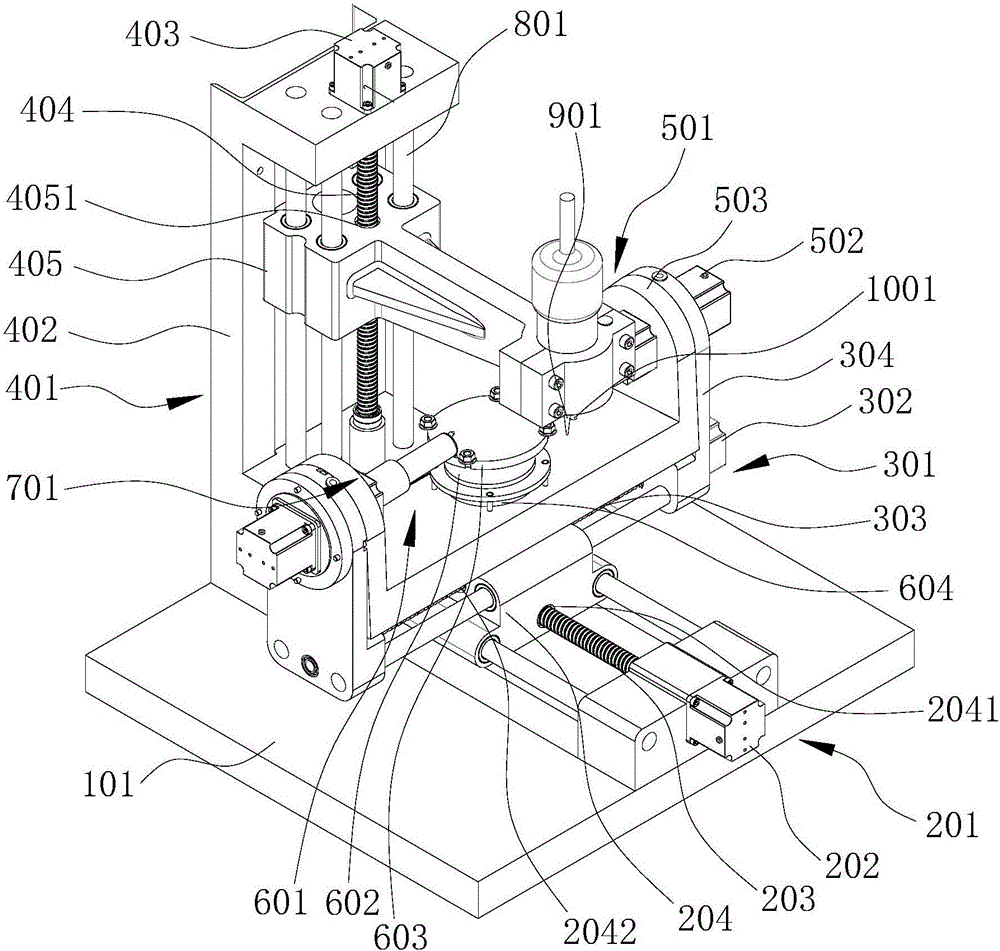

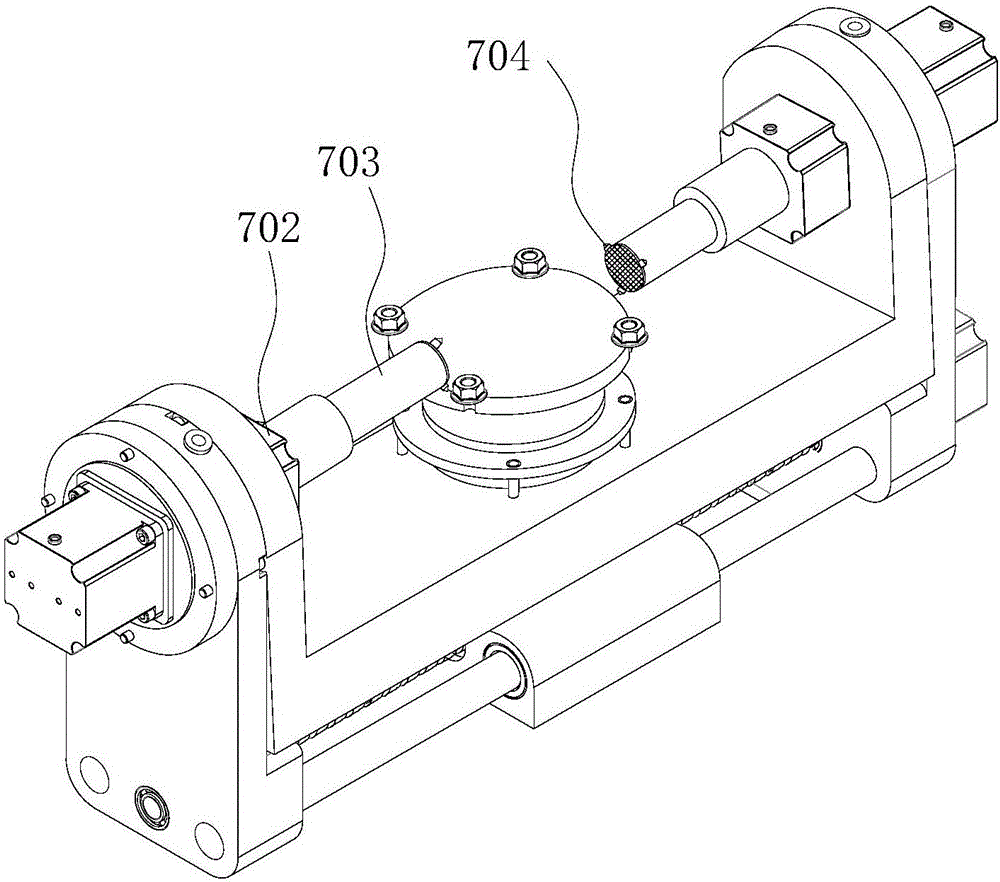

[0053] See figure 1 , figure 1 It is a schematic structural diagram of a five-axis linkage laser cutter in an embodiment of the present invention. The five-axis processing platform includes a platform base 101, a Y-axis movement module 201, an X-axis movement module 301, a Z-axis lifting module 401, and an A-axis rotation module 501, C The shaft rotation module 601 and the turning module 701. The first driving motor 202 of the Y-axis moving module 201 is arranged on the platform base 101, and the power output shaft of the first driving motor 202 is connected to the first ball screw 203, the first ball screw 203 The Y bearing platform 204 is connected through the first threaded hole 2041, the second drive motor 302 of the X-axis moving modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com