Lake silt clearing device and method

A technology for clearing equipment and sludge, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc. It can solve problems such as incomplete dredging, weakened water storage capacity, and low production efficiency. Achieve the effect of saving manpower and time, improving speed and efficiency, and maintaining stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

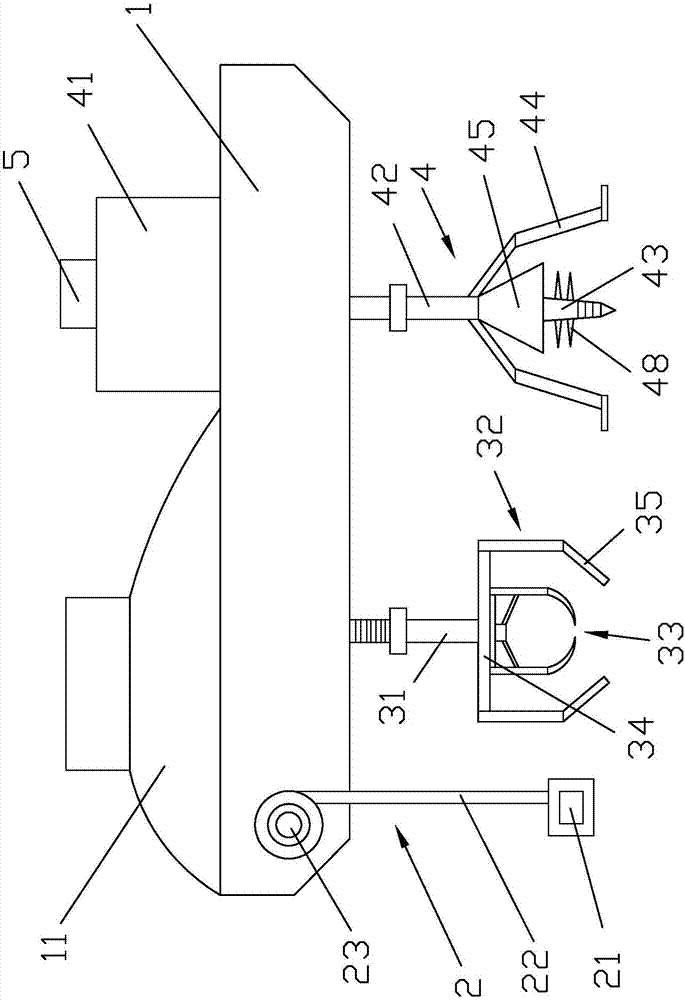

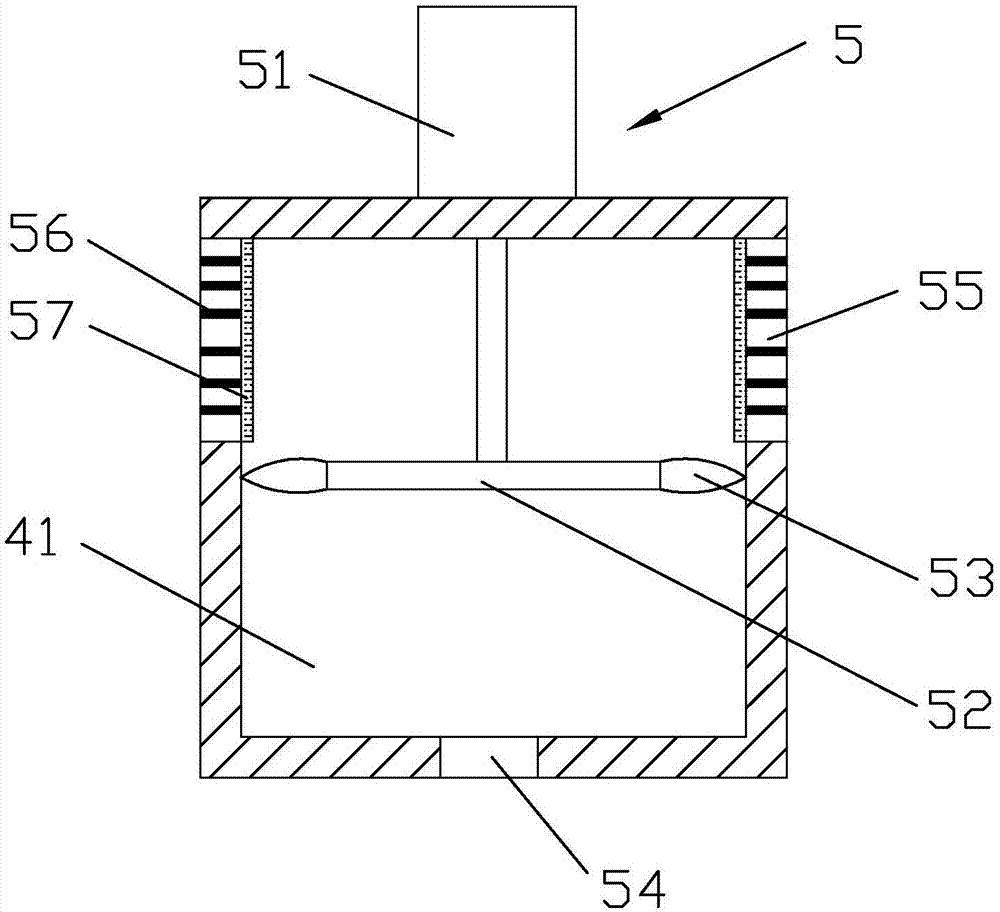

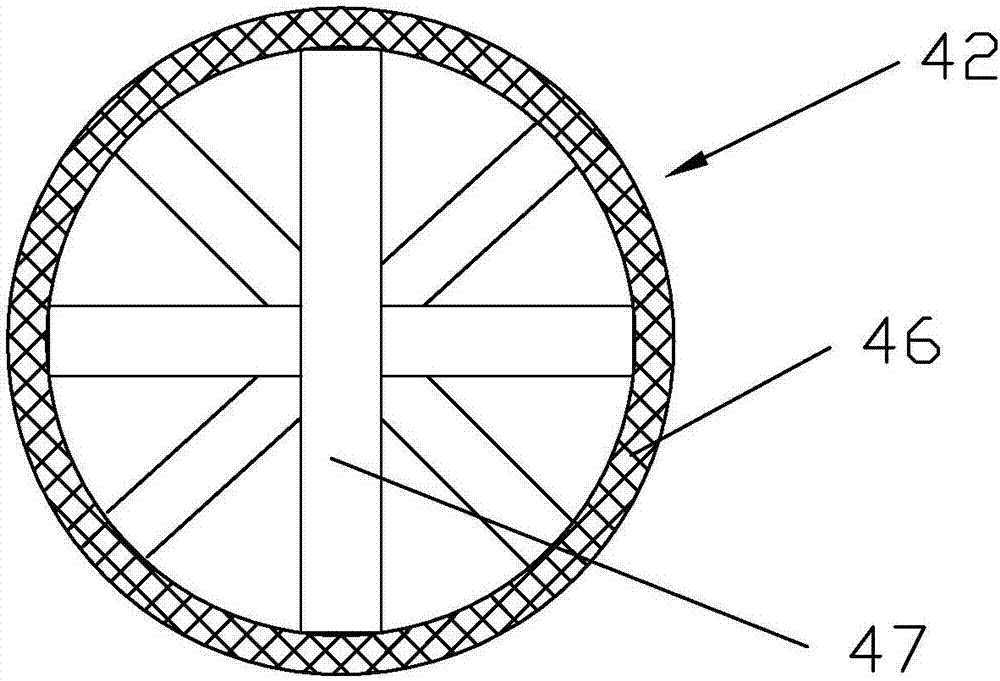

[0043] Such as Figure 1-3 As shown, it is a lake silt cleaning device of the present invention, which includes a hull 1, a detection device 2, a grabbing device and a mud suction device 4, and the detection device 2, the grabbing device and the mud suction device 4 are sequentially from left to right Installed under the hull 1, the hull 1 is provided with a control cabin 11, and a controller is arranged in the control cabin 11, and the controller is connected with the detection device 2, the grasping device and the mud suction device 4 respectively. The detection device 2 comprises a detector 21, a lifting rope 22 and a hoist 23, the detector 21 is wound on the hoist 23 by the lifting rope 22, the detection device 2 detects the bottom of the lake, and according to the depth of the bottom of the lake, the hoist 23 is used to detect the bottom of the lake. Control the working length of the lifting rope 22, so that the detector 21 is put into the bottom of the lake, detects the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com