Bar material conveying device

A conveying device and bar technology, which is used in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of lack of grabbing space for bars, affecting the grasping and grabbing accuracy of robotic arms, and easy to slip.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

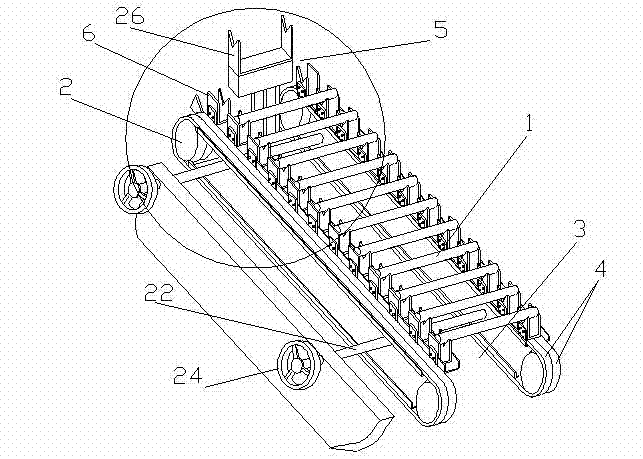

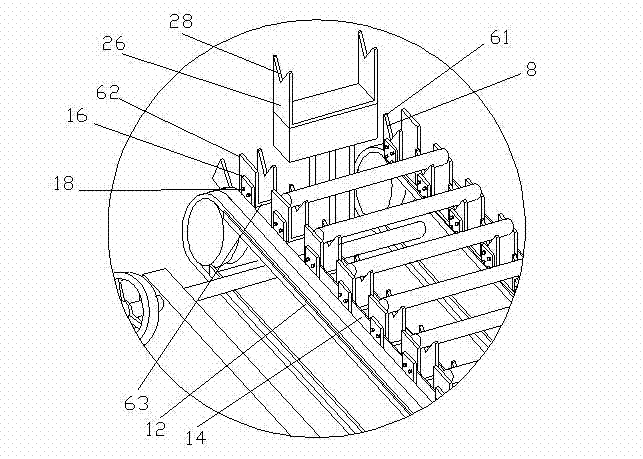

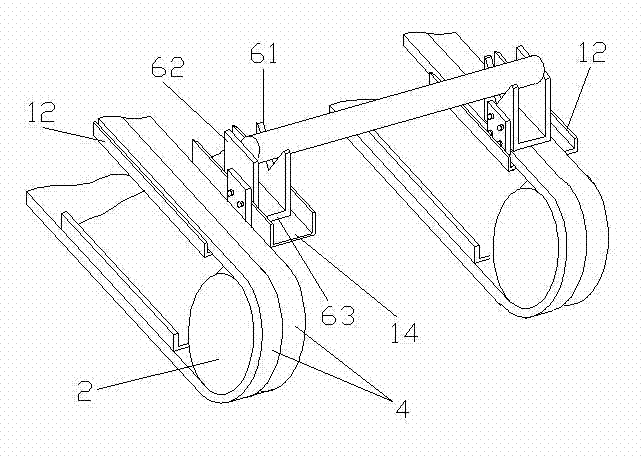

[0020] Embodiment 1: as Figure 1-3 As shown, a bar conveying device of the present invention includes a horizontal conveyor containing two conveying groups with the same conveying direction, a distance adjusting device for adjusting the horizontal distance between the two conveying groups, and a conveying outlet located at the two conveying groups end vertical lifting device. The transmission group is composed of a drive assembly 2 and an endless belt traction assembly, wherein the belt traction assembly is composed of two parallel endless chains 4, and the drive assembly 2 is a gear. Each belt traction assembly is provided with a row of bar seats 6 along the conveying direction. Two rows of bar seats 6 are arranged in parallel, the number of bar seats 6 in each row is equal to the number of bar seats 6 in the other row, and they correspond one by one; the corresponding two bar seats 6 form a group, and The positions in the directions are the same, and the heights relative ...

Embodiment 2

[0022] Embodiment 2: Another bar conveying device (not shown) of the present invention differs from Embodiment 1 only in that it includes two horizontal conveyors arranged in parallel in the conveying direction, and the corresponding two horizontal conveyors respectively lifting device. Moreover, the screw mandrel 22 in the distance adjusting device connects the four conveying groups, and can adjust the distance between the respective conveying groups in the two conveyors. Working with the bar conveying device in Embodiment 2 is equivalent to doubling the conveying capacity, and the two horizontal conveyors work at the same time, which greatly improves the working efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com