Hole cleaning device for spun-digging pile hole and construction method thereof

A technology of hole cleaner and rotary digging pile, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problem of difficult cleaning of sediment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

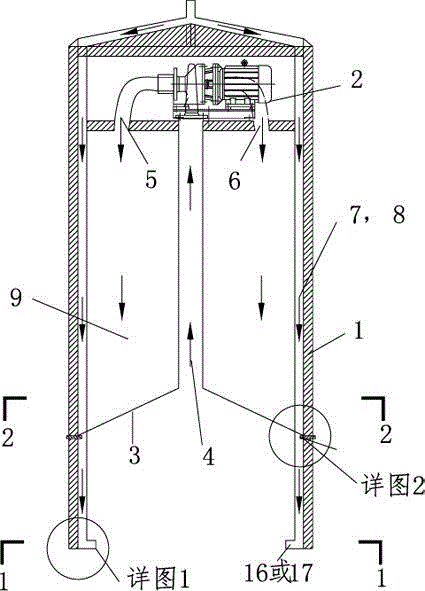

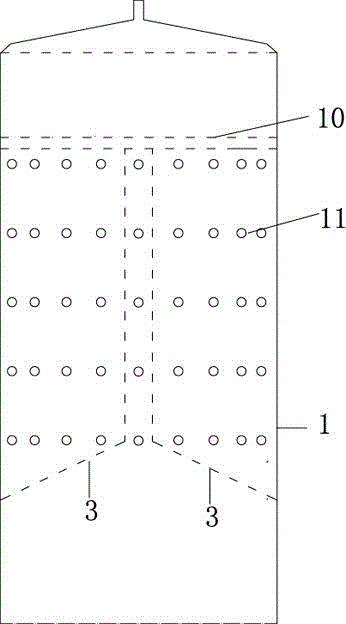

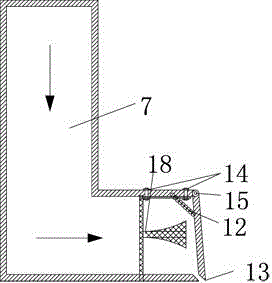

[0019] Such as Figure 1-Figure 7 As shown, the rotary excavation pile hole cleaner of the present invention includes a cylindrical hole cleaner steel casing 1 evenly provided with water filtering holes 11, a slag pump 2, a filter screen 3, a circular center slag discharge hole 4, a second First slag outlet 5, second slag outlet 6, compressed gas pipeline 7, foam agent pipeline 8, sediment collection chamber 9, steel plate 10, spring 12, rubber sheet 13, fastening bolt 14, rotating bolt 15, compressed gas outlet 16. Foam agent outlet 17, gas distributor 18, clamp 19, filter screen fastening bolt 20, circular insert rod 21, filter screen rotating bolt 22, steel cable 23, guide wheel 24 and fixed shaft 25; The water filter hole 11 is circular and penetrates the wall of the cylindrical hole cleaner, and a geotextile with water filtering function is arranged inside the water filter hole; the compressed gas pipeline 7 is circular and fixed on the inner wall of the cylindrical hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com