3D printing head with pressure sensing high-temperature-resisting pulp

A technology with high temperature resistance and printing head, applied in the field of 3D printing head, it can solve the problems of narrow application range, equipment damage, and difficulty in maintenance and cleaning of 3D printing head, so as to achieve the effect of solving the difficulty of maintenance and cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with drawings and embodiments.

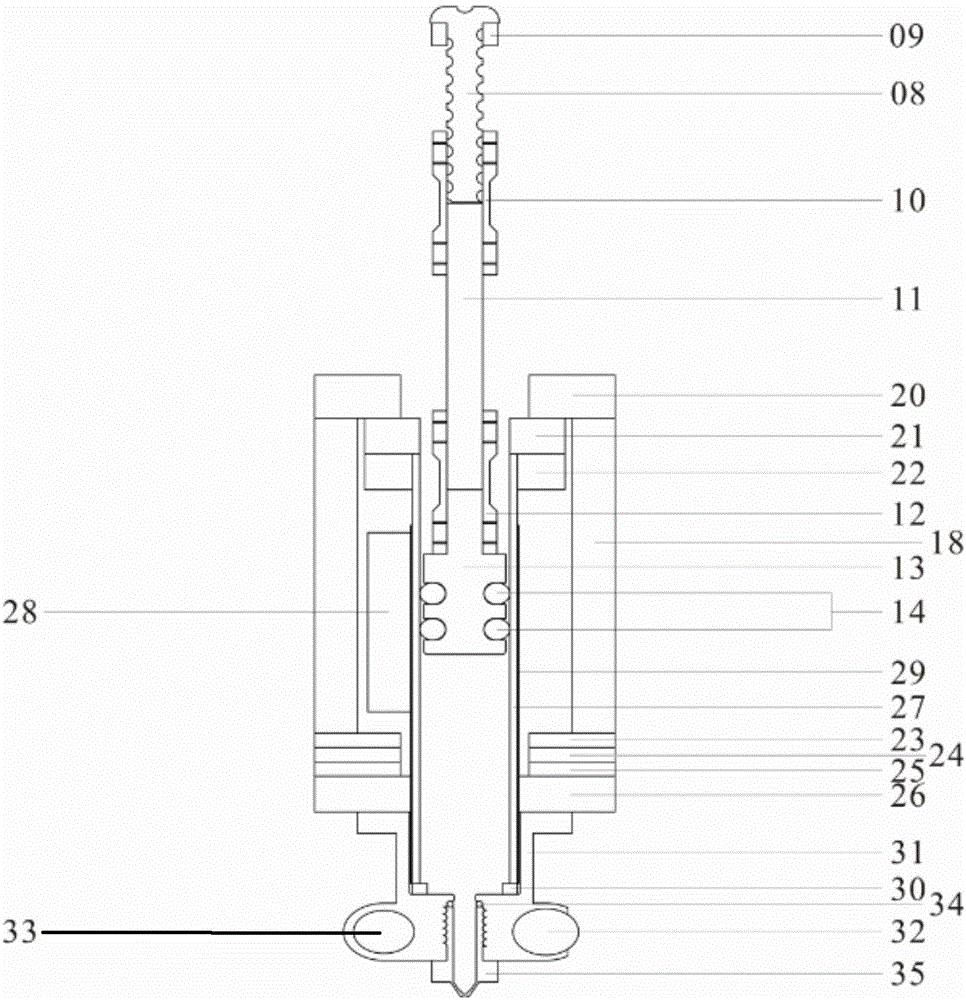

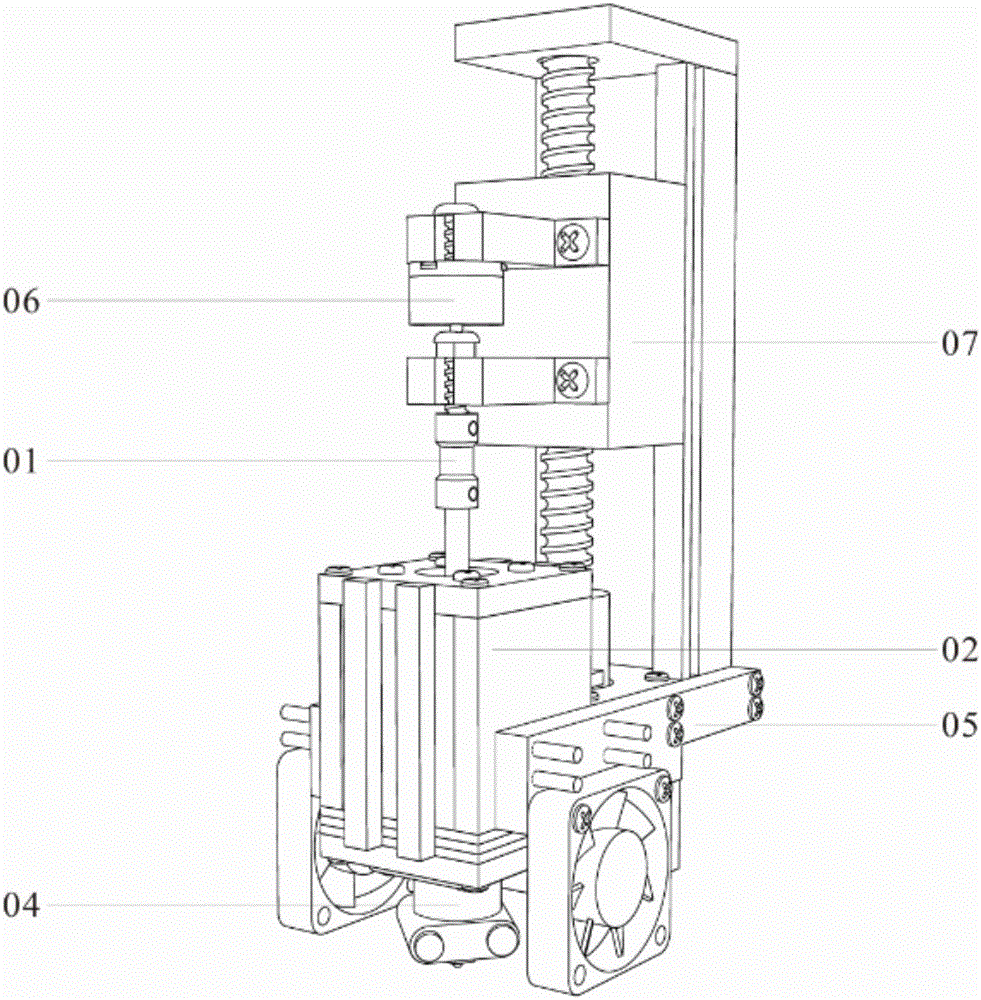

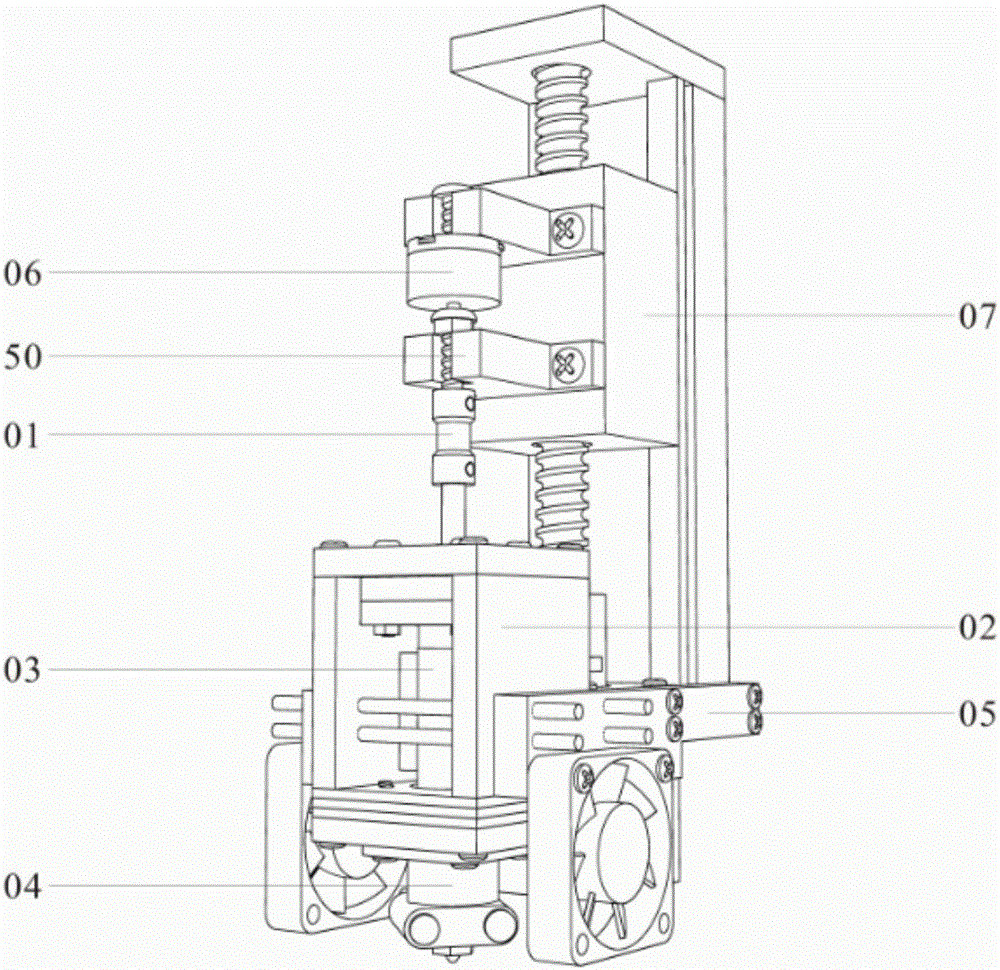

[0030] The invention provides a 3D printing head with pressure-sensitive and high-temperature-resistant slurry, which is installed on a three-axis linkage platform. Figure 1 to Figure 4 , including a linear displacement mechanism module 07, a connection module 05, a thermal insulation bin module 02, a discharge module 04, a material storage module 03, a pressure sensor module 06, and an extrusion push rod module 01. The transmission module 07 is installed on the ready-made three-axis linkage platform (not shown), one end of the connection module 05 is set on the transmission module 07, the other end is set on the heat insulation bin module 02, and the discharge module 04 is placed in the heat insulation bin On module 02, the ejection direction of the discharge module 04 points to the printing plane of the three-axis linkage platform (not shown), and the storage module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com