Glue feeding system with automatic glue proportioning function

A technology of automatic proportioning and glue, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of difficulty, low production efficiency, easy curing and cleaning of glue, etc., and achieve the effect of good economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

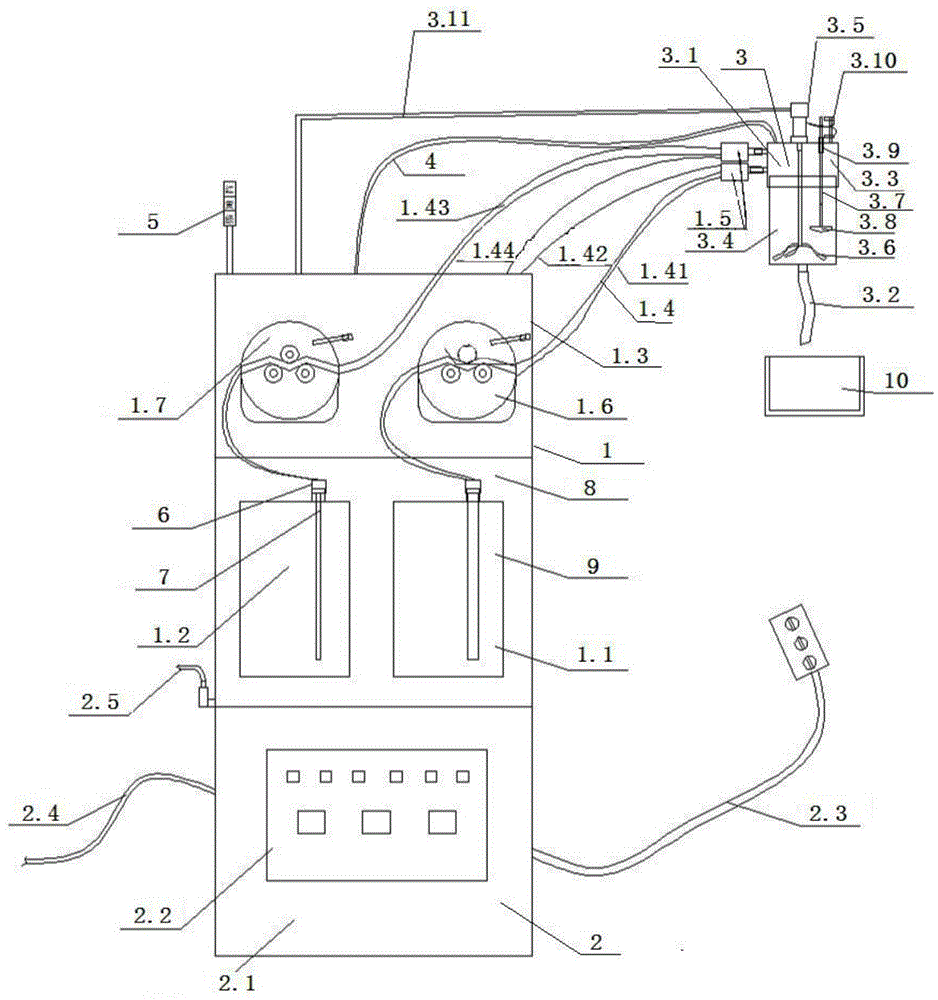

[0020] The glue automatic proportioning and adding glue system shown in the figure includes AB glue mixer 1, control device 2 and AB glue mixing and dispensing device 3;

[0021] The control device 2 includes a control cabinet 2.1 and a control system 2.2. The control cabinet 2.1 is respectively connected to a control switch 2.3, an input power supply 2.4 and an input gas source 2.5. The control device 2 is connected to the signal receiving end of the AB glue mixer 1;

[0022] AB glue mixer 1 includes A glue barrel 1.1, B glue barrel 1.2 and AB glue output unit 1.3; AB glue output unit 1.3 includes AB glue output pipeline 1.4 and AB glue volume controller 1.5, and AB glue output pipeline 1.4 passes through A glue respectively Peristaltic pump 1.6, B glue peristaltic pump 1.7 are connected with A glue barrel 1.1, B glue barrel 1.2; AB ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com