All-in-one machine for shell fabric washing and drying

A technology of washing, drying and all-in-one machine, applied in the field of machinery, can solve the problems of fabric pollution, messy fabrics, troublesome finishing, etc., and achieve the effects of saving water resources, simple structure, and solving difficult cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

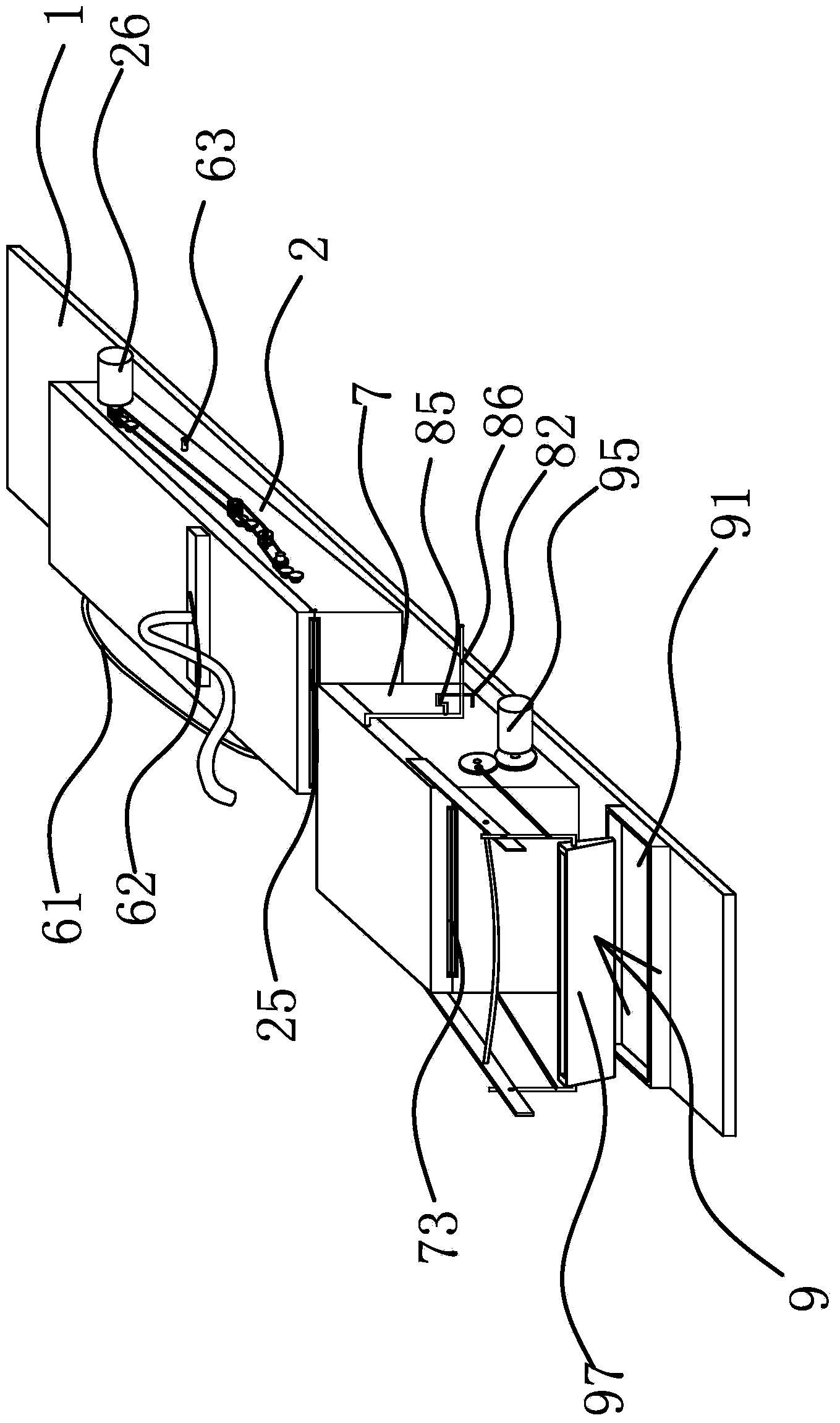

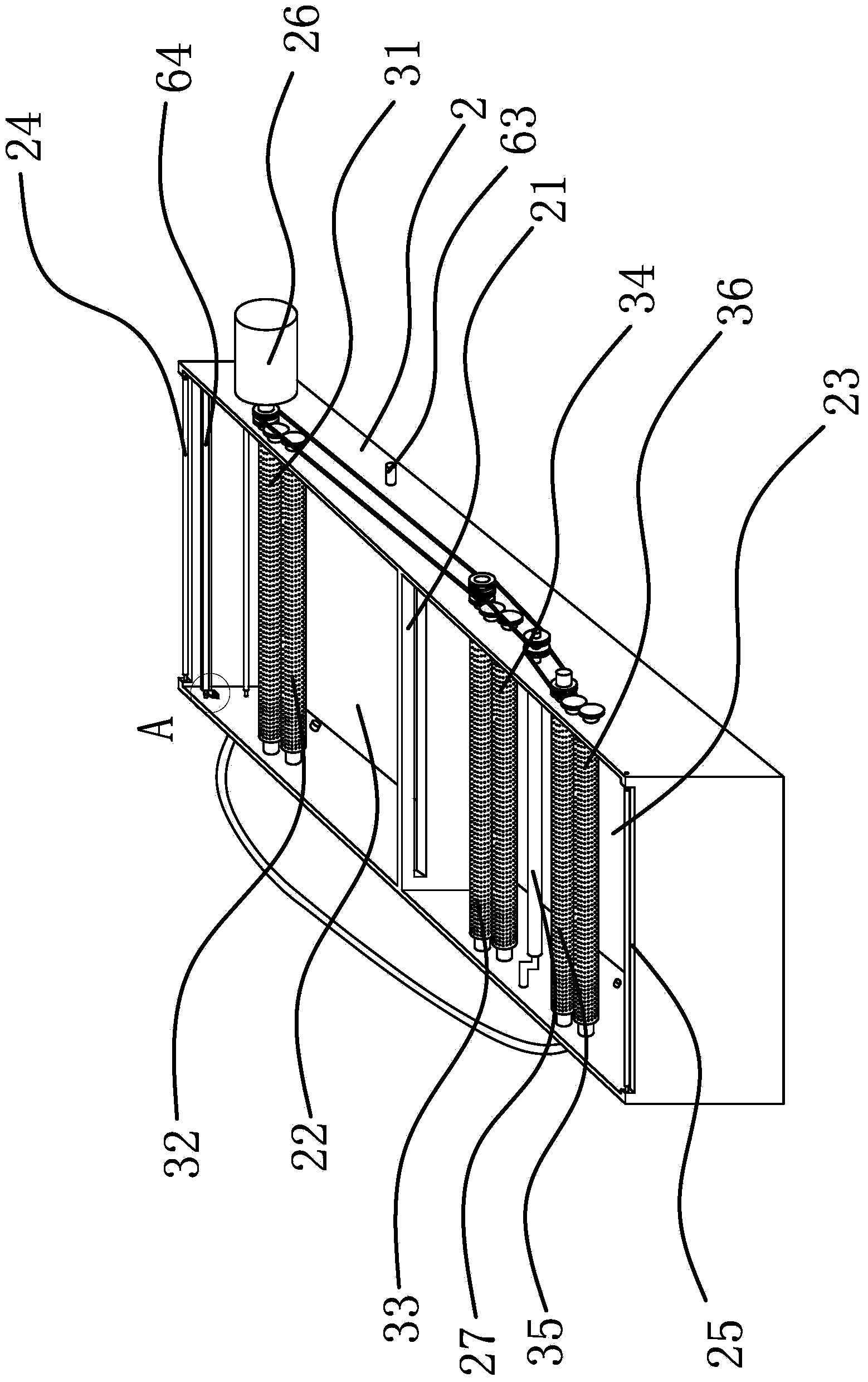

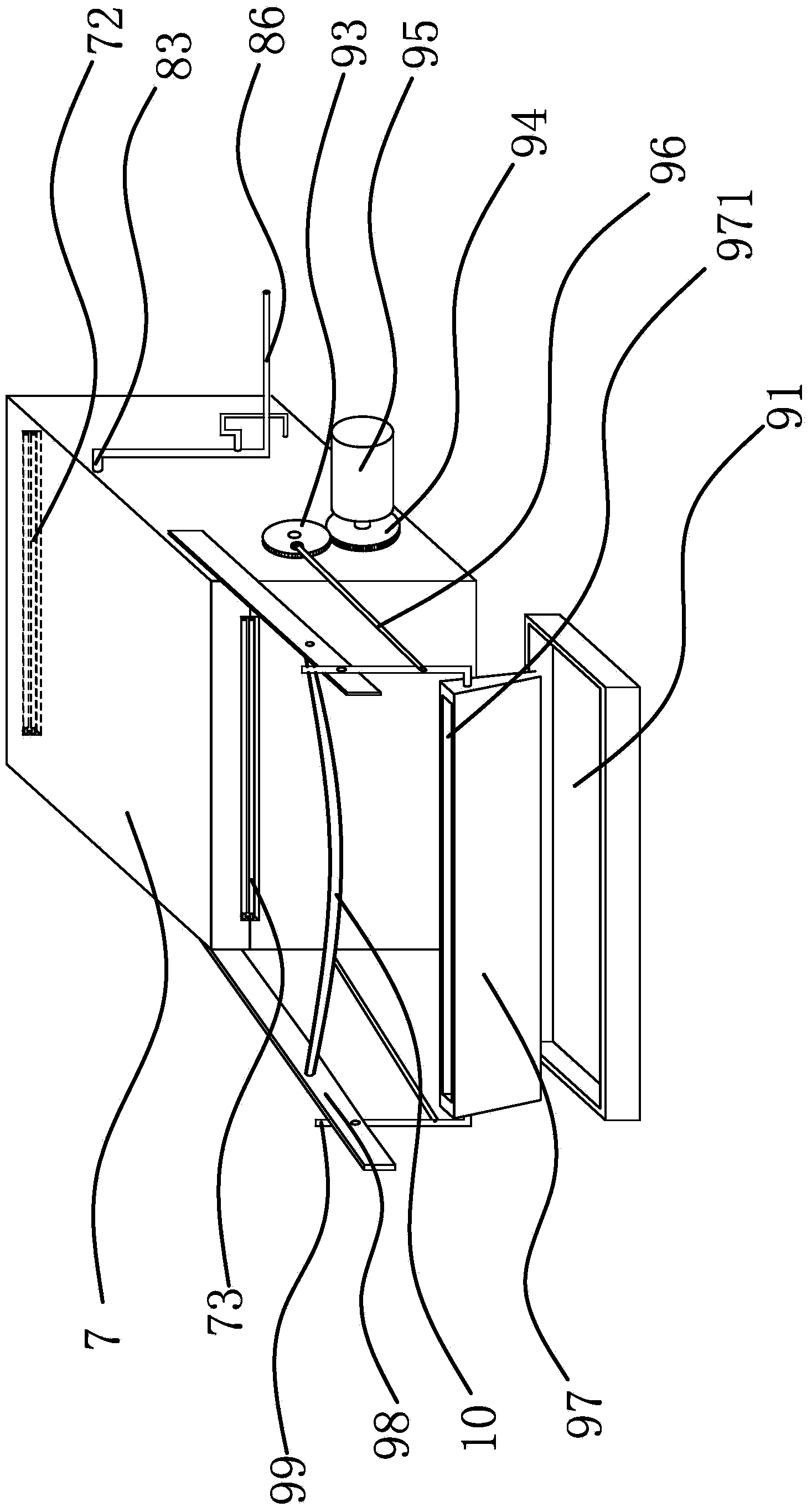

[0030] Such as figure 1 , figure 2 , Figure 6 and Figure 7 As shown, a fabric washing and drying machine includes a base 1, on which a washing box 2 is arranged, and the middle part of the washing box 2 is divided into a washing tank 22 and a rinsing tank by a partition 21 23. The two ends of the washing box 2 are respectively provided with a fabric inlet 1 24 and a fabric outlet 2 73, and the inner wall of the washing box 2 is provided with two mutually parallel washing drums 1 31 and 2 washing drums 32, washing drum 1 31 and washing drum 2. Cylinder two 32 are all in the washing tank 22, and washing cylinder one 31 is driven by a drive motor one 26, and the cylinder shaft of washing cylinder one 31 is fixedly provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com