Crane steel wire rope complete lubricating integrated machine

A technology of steel wire rope and integrated machine, which is applied in the direction of lubricating parts, engine lubrication, mechanical equipment, etc., can solve the problems of steel wire rope life discount, etc., and achieve the effect of low maintenance cost, safe and reliable operation, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

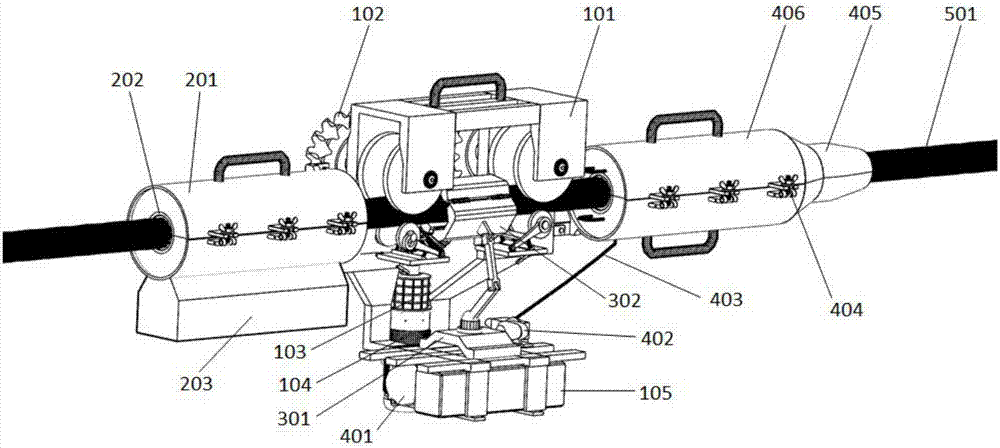

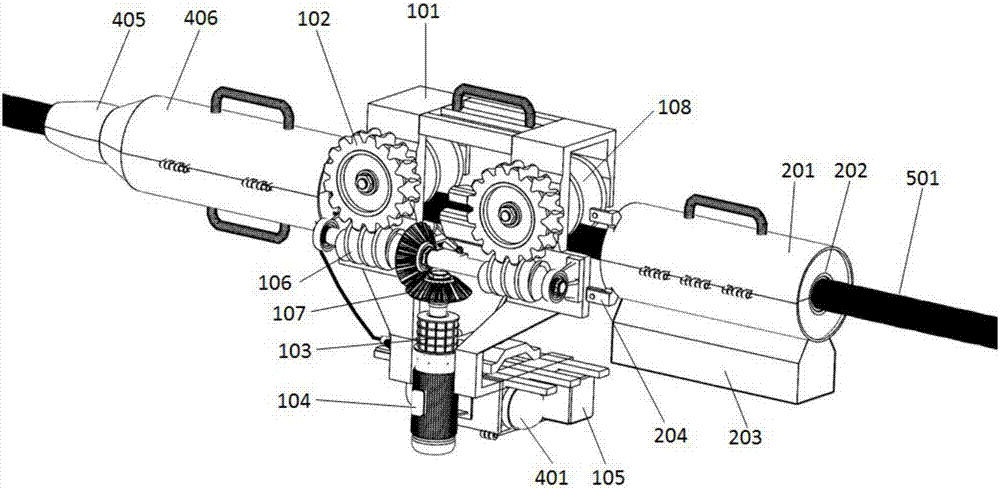

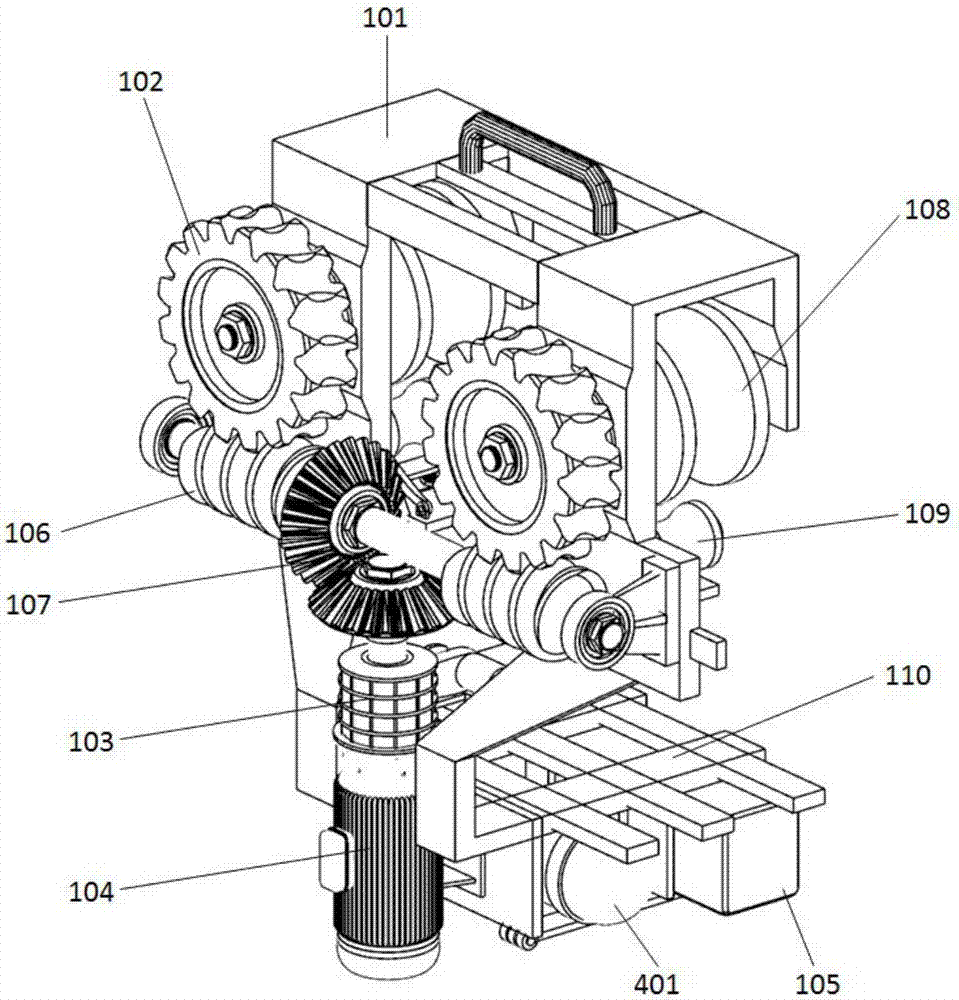

[0030] as attached Figure 1 to Figure 7 As shown, an all-in-one lubricating machine for crane wire ropes includes a power module (101-117), an old oil cleaning module (201-203), a wire rope detection module (301-302), a wire rope Grease injection lubrication modules (401-405). The power module is arranged on the crane wire rope 501 and can move along the crane wire rope 501; the old oil cleaning module and the wire rope grease injection lubrication module are respectively arranged on the front and back sides of the power module, and pass through The link pin shaft 204 is connected with the power module; the wire rope inspection and flaw detection module is directly mounted on the power module. The power module provides power for the entire integrated lubrication machine. Driven by the power module, the steel wire rope old oil cleaning module, the steel wire rope det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com