Oxidation washing system equipment based on new resin material treatment

A technology of system equipment and new materials, applied in the field of oxidative washing system equipment, can solve the problems of easy leakage of liquid, inability to achieve temporary collection, difficulty in cleaning, etc., and achieve the effect of improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

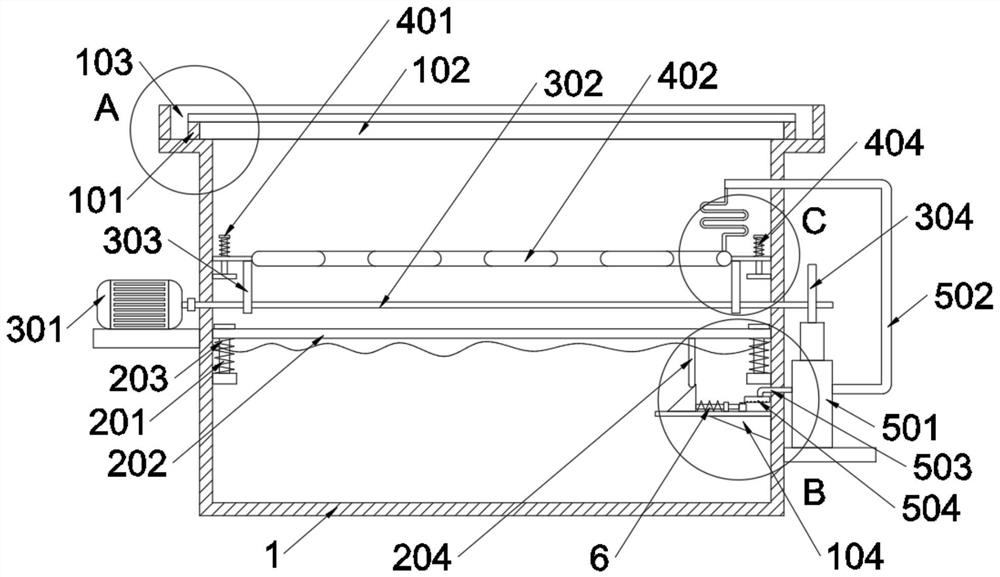

[0035] as attached figure 1 to attach Figure 9 Shown:

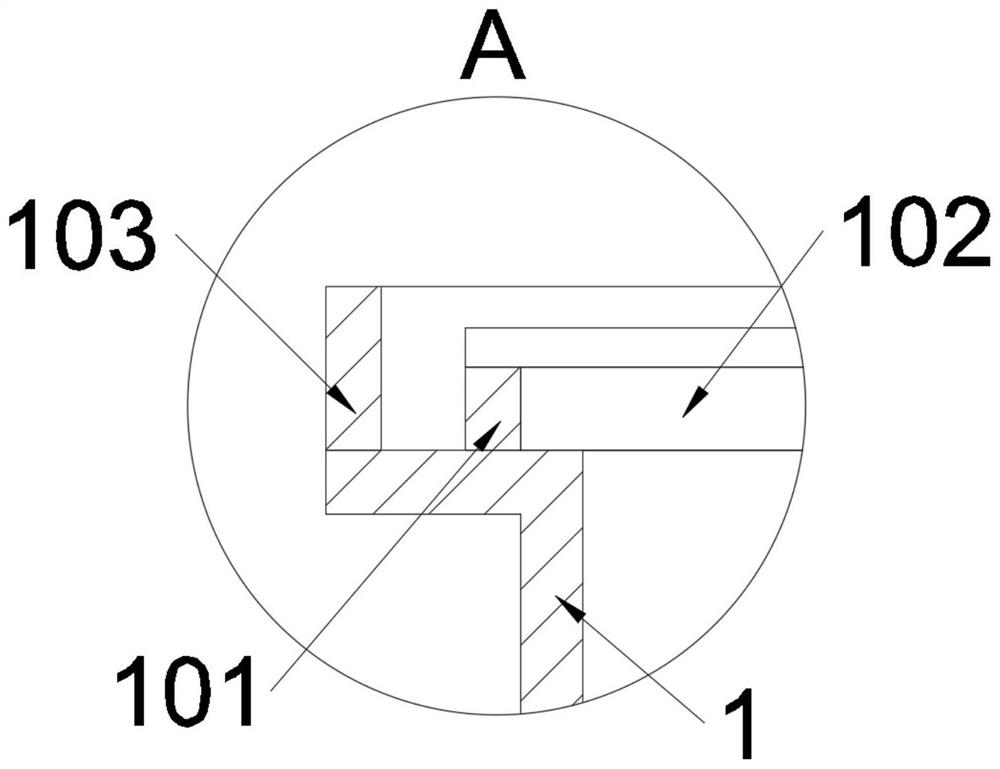

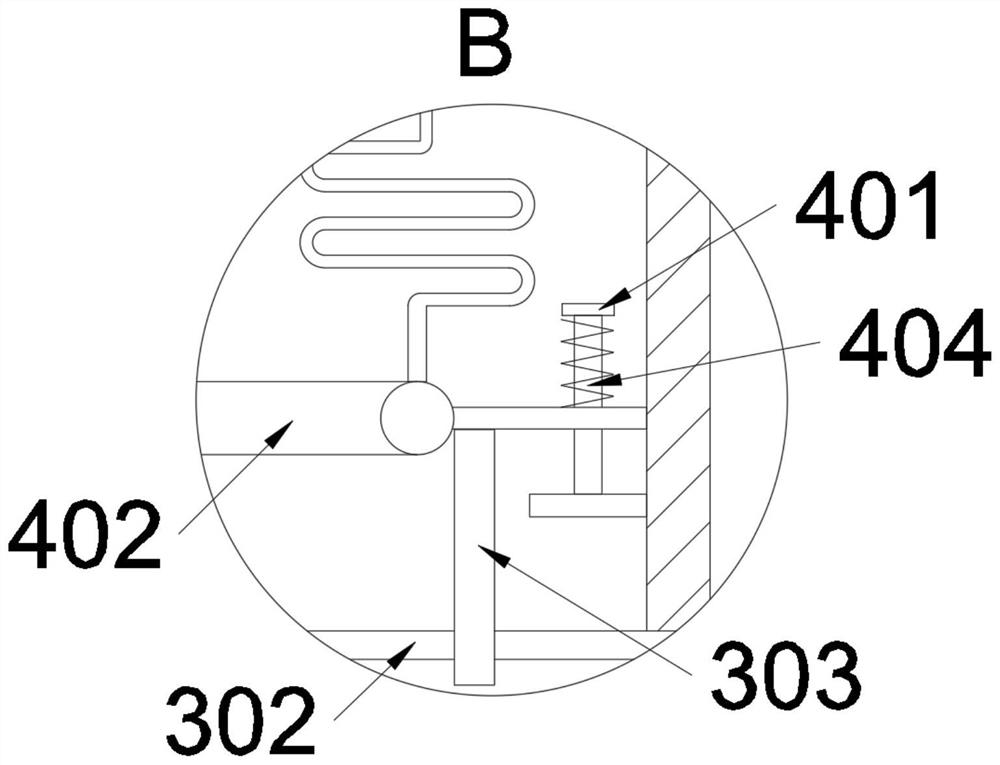

[0036] The present invention provides oxidation washing system equipment based on resin new material treatment, including a box body 1; liquid is filled in the box body 1, and a vibration cleaning structure 2 is installed in the box body 1; a driving structure 3 is also installed in the box body 1, And the spray structure 4 is also installed in the box body 1; the air jet structure 5 is installed on the box body 1, and the cleaning structure 6 is also installed in the box body 1; refer to as figure 2 , the box 1 includes a retaining ring B103 and a mounting seat 104, the box body 1 is a rectangular box structure, and a mounting seat 104 is welded on the inner wall of the box body 1; the connecting flange on the box body 1 is welded with a retaining ring B103, and The retaining ring B103 is not in contact with the retaining ring A101; an annular groove is formed between the retaining ring B103 and the retaining ring A1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com