Dismountable cross-flow type filter for liquid with high viscosity

A filter, high-viscosity technology, used in fixed filter element filters, filter regeneration, filter separation, etc., can solve the problem that the O-ring is not a high-pressure sealing method, cannot be cleaned of impurities from the filter screen, and the high-pressure filter seal has Difficulties and other problems, to achieve the effect of solving difficult cleaning, small size and prolonging working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

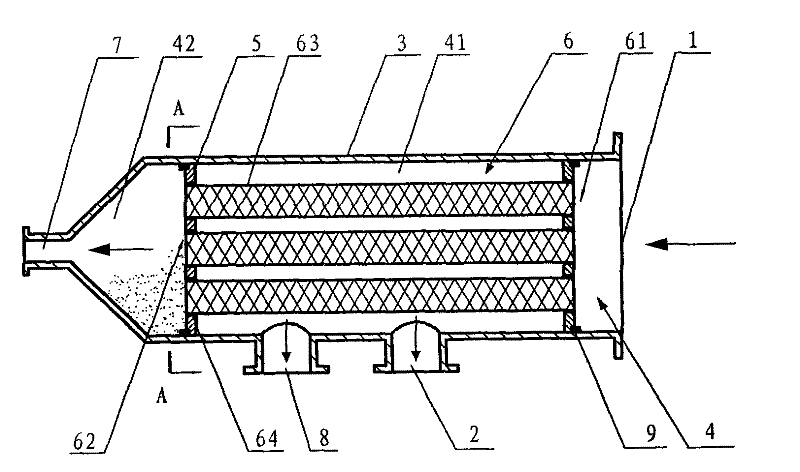

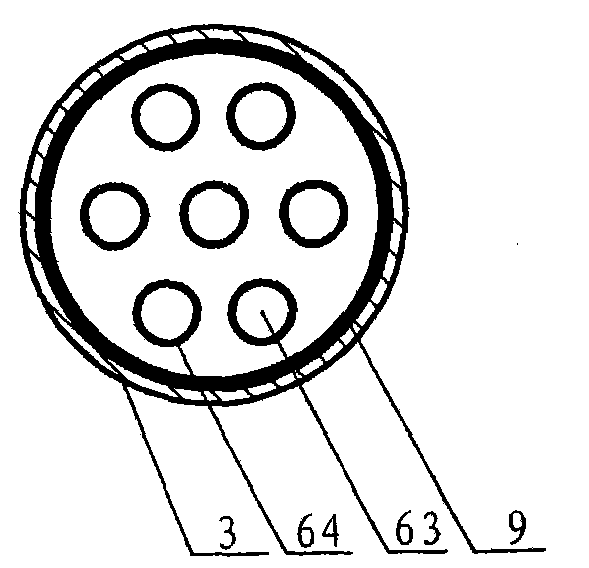

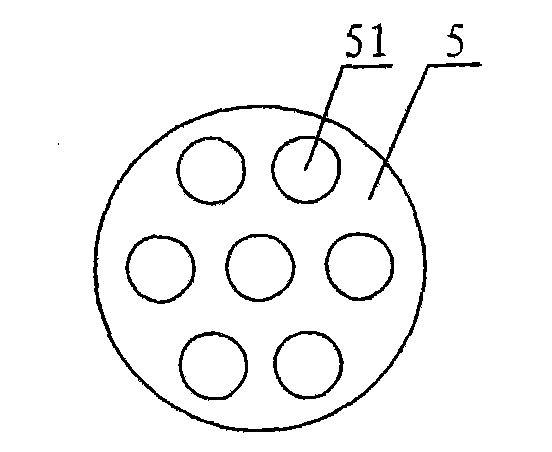

[0028] Such as figure 1 As shown, a detachable cross-flow filter for high-viscosity liquid includes a filter housing 3 with a raw liquid inlet 1 and a filtrate outlet 2, and a filter cavity 4 is arranged inside the filter housing 3, and the raw liquid The inlet 1 is located at one end of the filter housing 3, and the filtrate outlet 2 is located on the outer surface of the filter housing 3. Both the raw liquid inlet 1 and the filtrate outlet 2 are connected with the filter cavity 4, and the filter cavity 4 is provided with a The filter chamber 4 is divided into the filter treatment area 41 and the orifice plate 5 of the residual liquid storage area 42. The orifice plate 5 and the filter housing 3 are sealed by an orifice sealing ring 9, which can also be sealed by welding or bonding.

[0029] Both orifice plates 5 are provided with installation holes 51 for fixing the filter pipe system 6, the filter pipe system 6 is fixed between the two orifice plates 5, and the filter seal ...

Embodiment 2

[0033] In this implementation, the same part as in Example 1 will not be repeated, and the difference is that: the diameter range of the filter net tube is 100 mm; the mesh aperture is 100 μm; the length is 60 cm.

Embodiment 3

[0035] In this implementation, the same parts as in Examples 1 and 2 will not be repeated, and the difference is that the high-viscosity liquid is a detachable cross-flow filter with a diameter range of 300mm; the mesh aperture is 500 μm; the length is 140cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com