Airflow blow and suction vibration cleaning method and device of engine cylinder cover

A technology for an engine cylinder head and a cleaning device, which is applied to cleaning methods using gas flow, engine components, machines/engines, etc., can solve problems such as high manufacturing and maintenance costs, aluminum scraps stuck in bends, and aluminum scraps retention. , to achieve the effect of solving the cleaning problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] This embodiment is an explanation of the technical solution and claims of the present invention, and the protection scope of the present invention is not limited to the following structures.

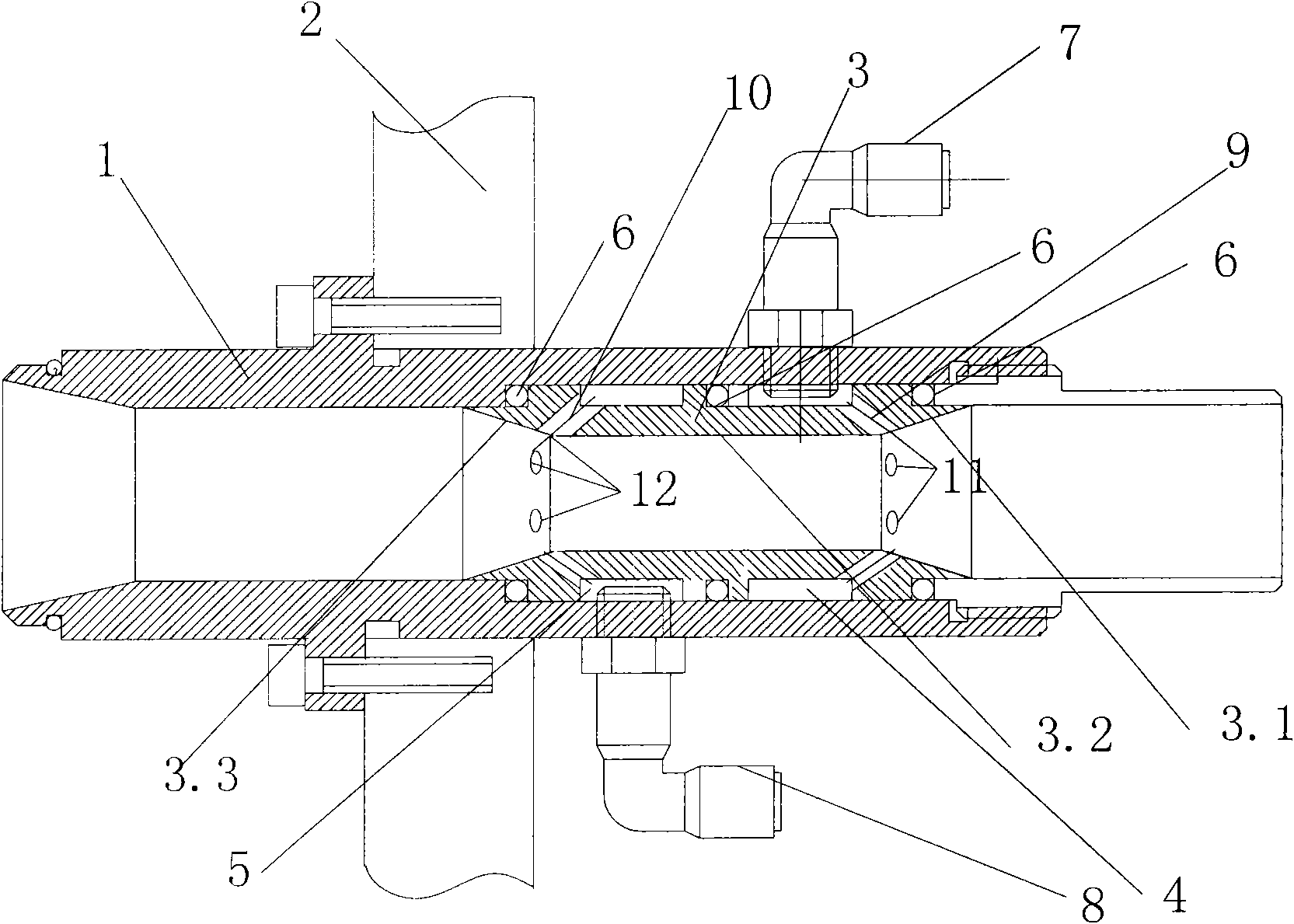

[0029] Such as figure 1 As shown, the engine cylinder head airflow blowing and oscillating cleaning device 30 includes an airflow channel tube 1 connected with a support plate 2; the airflow channel tube 1 is provided with a venturi tube 3, and the venturi tube 3 includes a contraction section 3.1, a throat tube 3.2, and Expand paragraph 3.3. The outer pipe wall of the venturi 3 is provided with a first air guiding groove 4 and a second air guiding groove 5 which are sealed and separated from each other. In this embodiment, the first air guiding groove 4 and the second air guiding groove 5 are along the axis It is also possible to arrange partitions on the same radial groove, and divide the same radial groove into two groove sections to form a first air guiding groove and a second ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com