Centrifugal static lampblack removal device

A lampblack device and centrifugal technology, applied in the field of centrifugal electrostatic lampblack removal device, can solve the problems such as weakening of the electrostatic field strength of the plate, heavy maintenance workload, and poor charging effect of lampblack, so as to solve the problem of difficult cleaning and good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

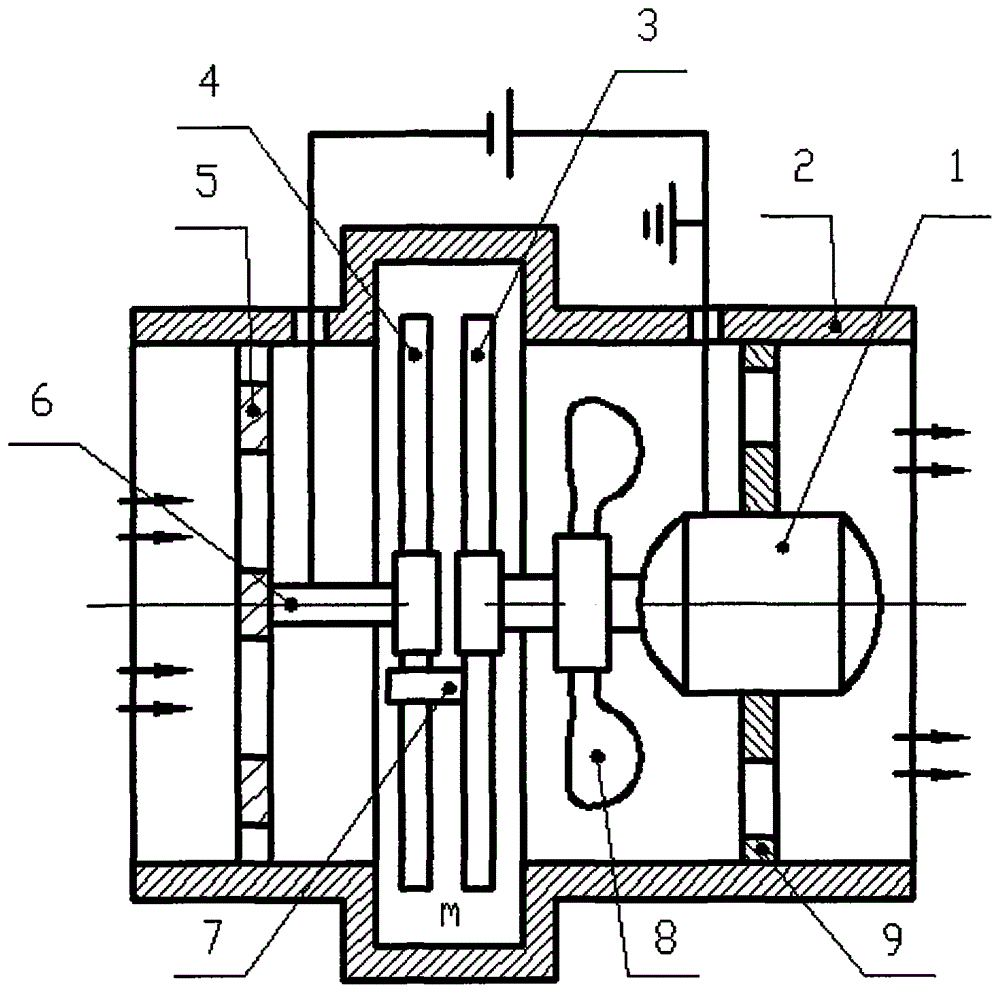

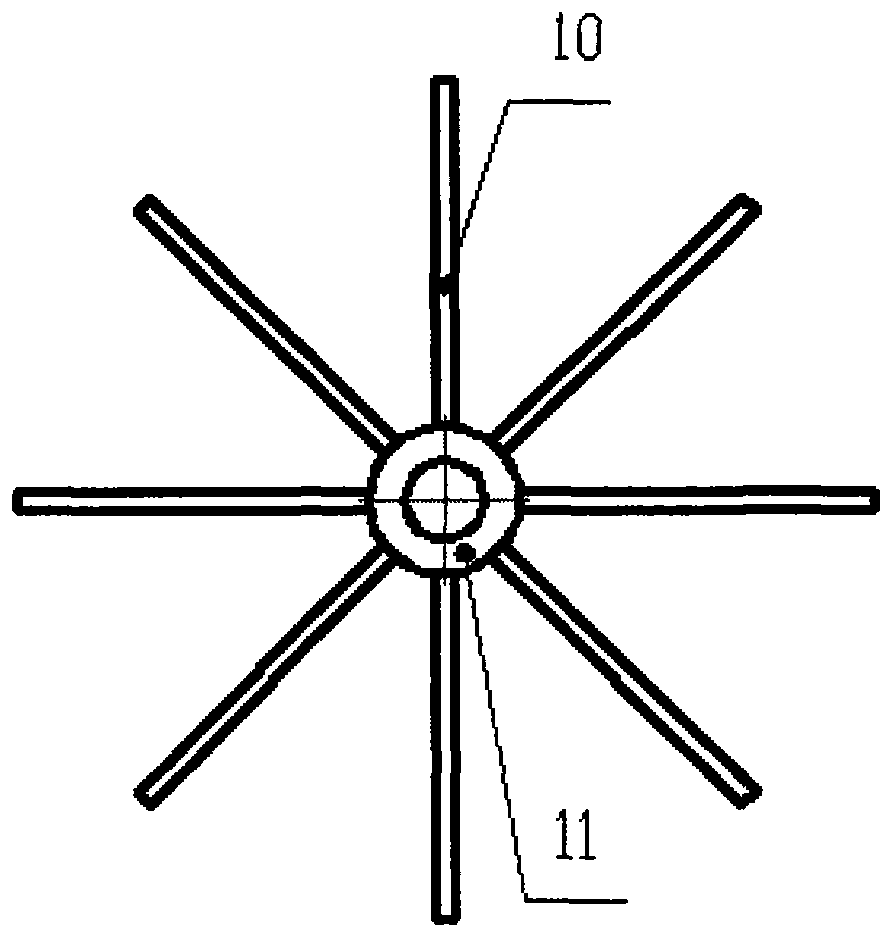

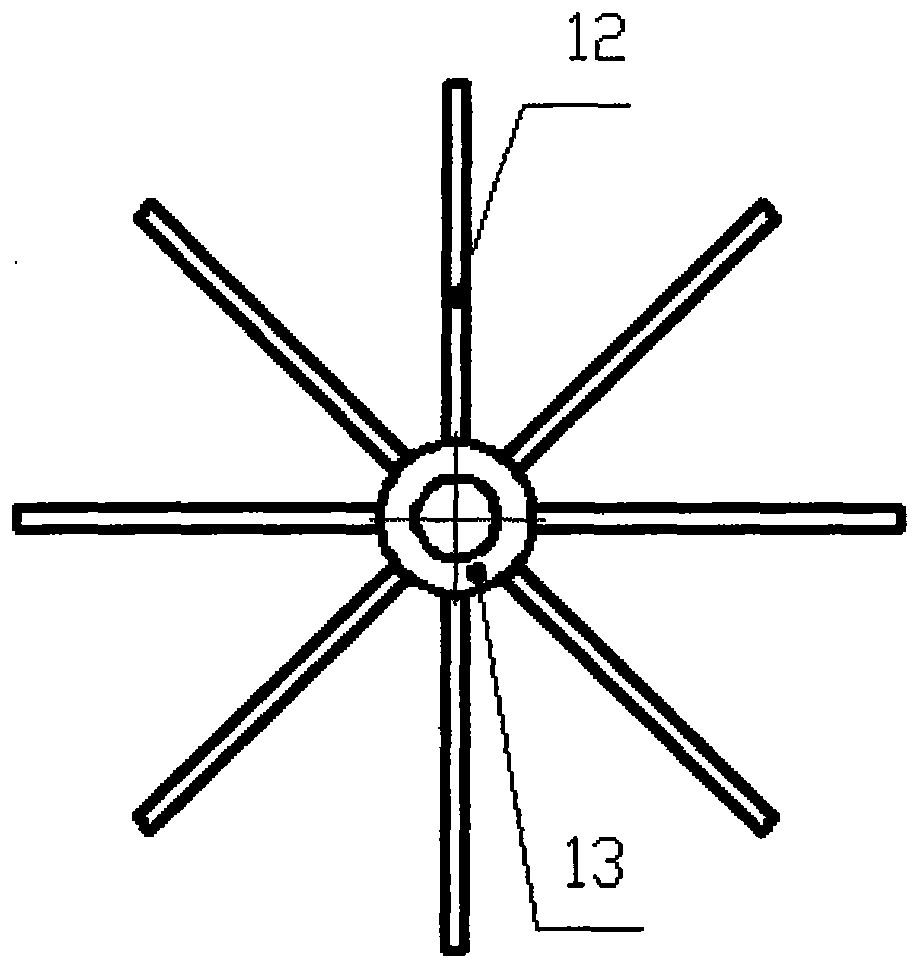

[0012] Attached below figure 1 , figure 2 and image 3 The specific implementation of a centrifugal electrostatic oil fume removal device according to the present invention will be further described in detail.

[0013] A centrifugal electrostatic oil fume removal device, including a motor (1), a channel (2), an anode (3) and a cathode (4); the cathode frame (5) is installed at the left end of the channel (2), and the motor frame (9 ) is installed at the right end of the channel (2), the motor (1) is installed on the motor frame (9), the positioning shaft (6) is installed at the center of the cathode frame (5), the positioning shaft (6) and the motor (1) The main shafts are in the same axial direction, the anode (3) is a disk-shaped structure composed of fried dough sticks (10) and anode sleeves (11), and the fried dough sticks (10) with a number greater than 1 are radially and evenly distributed and fixed on the On the anode sleeve (11), the cathode (4) is a disk-shaped st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com