Blasting fume removing device

A technology of gun smoke and spray tube, which is applied in the direction of spraying devices, liquid spraying devices, spraying devices with movable outlets, etc., which can solve the problems of weight gain and poor atomization effect, so as to prevent and occupational diseases and reduce toxic and harmful gases Concentration, the effect of reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

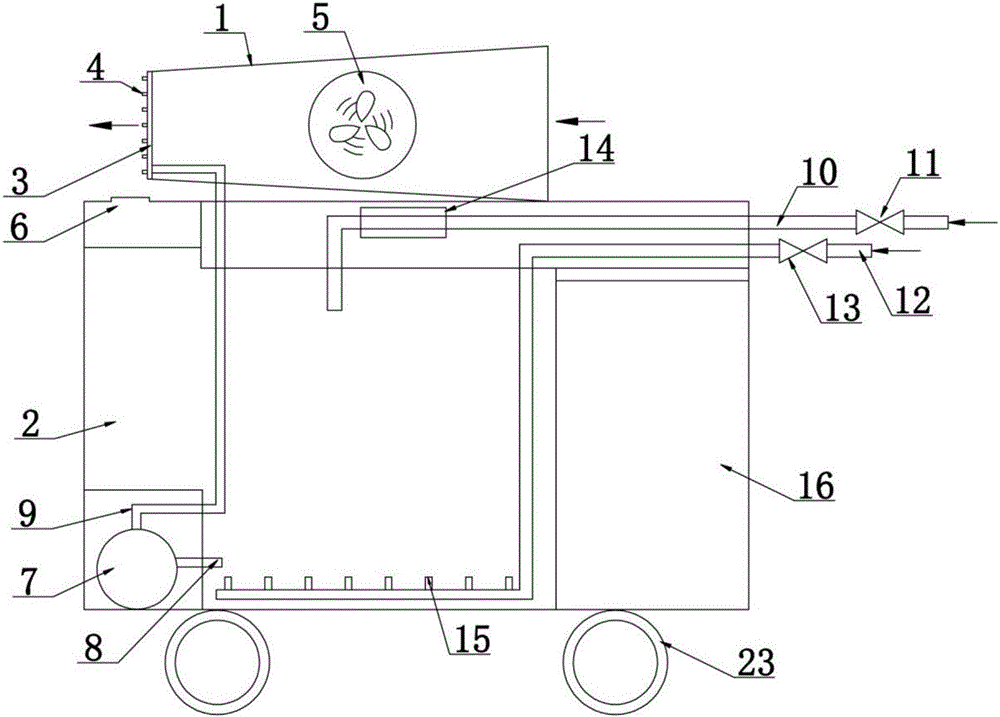

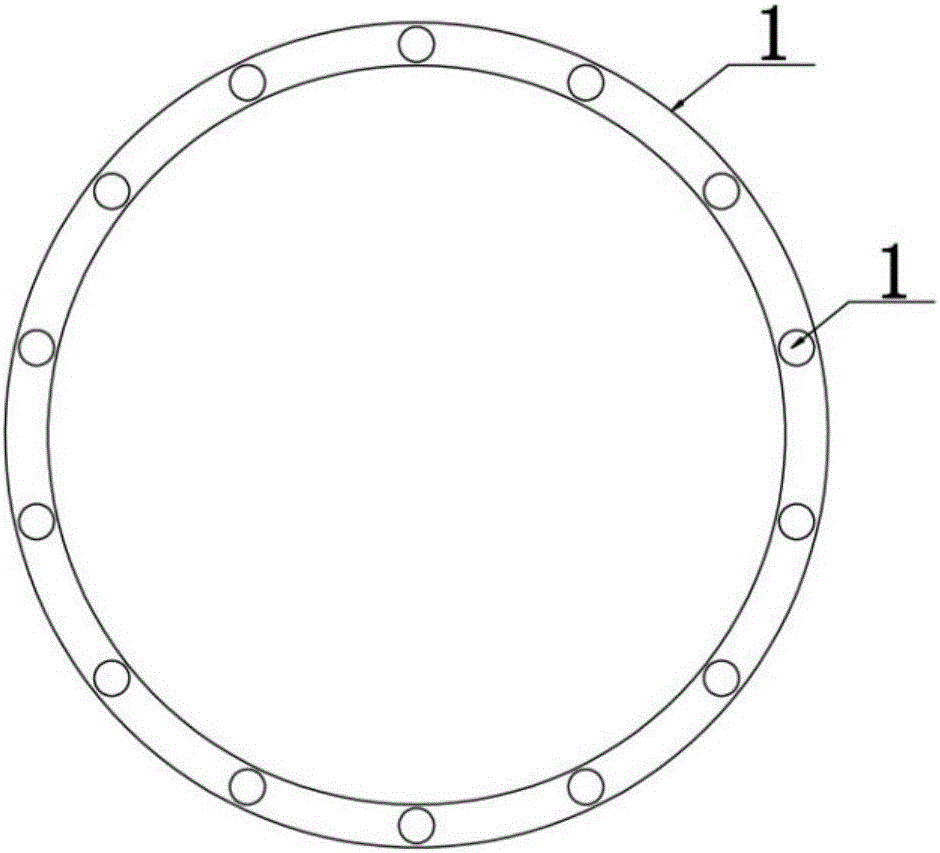

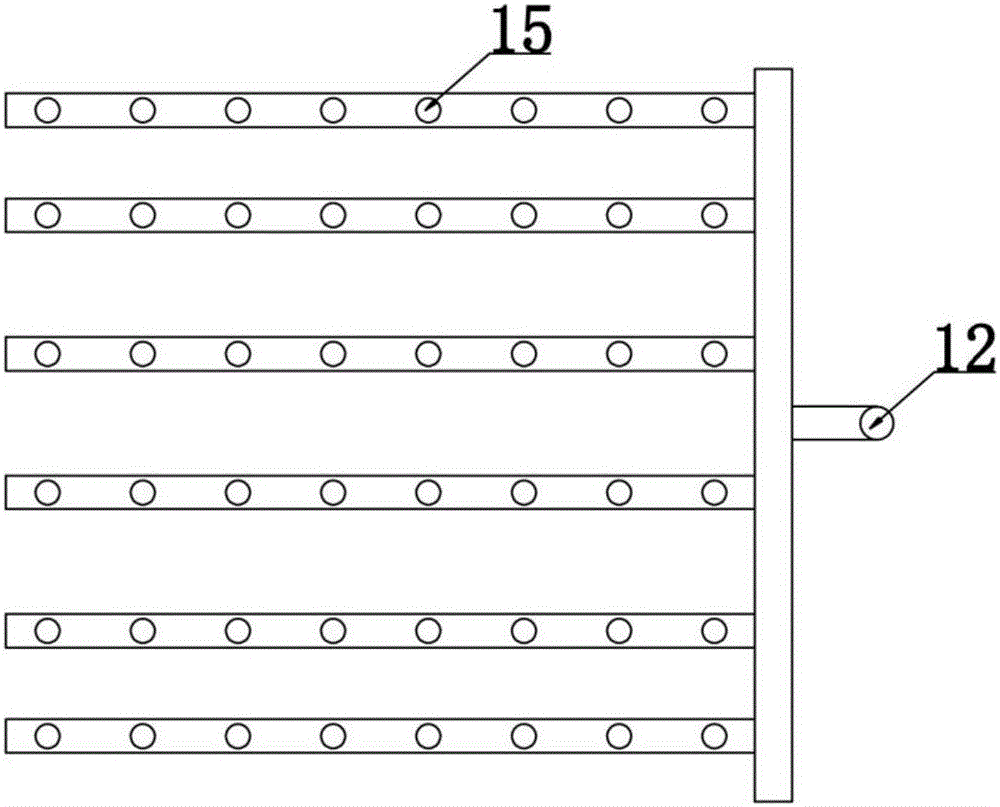

[0027] Example 1, such as Figure 1-3 As shown, a device for eliminating gun smoke includes a frame body, a spray tube 1, a water tank 2, a water inlet mechanism and an air intake mechanism, the spray tube is arranged on the top of the frame body, and the front end of the spray tube is provided with Annular spray pipe 3, a plurality of nozzles 4 are evenly distributed on the front side of the annular spray pipe, a fan 5 is arranged in the spray barrel on the rear side of the annular spray pipe, and the water tank is arranged on the Inside, the frame above the water tank is provided with a medicament inlet 6, a water inlet port and a high-pressure air port, one side of the water tank is provided with a pump chamber, and a water pump 7 is provided in the pump chamber, and the water pump The water inlet pipe 8 and the water outlet pipe 9 are arranged on it, the water inlet pipe leads to the water tank, the water outlet pipe communicates with the annular spray pipe, and the water ...

Embodiment 2

[0032] Example 2, such as Figure 4 As shown, the top of the spray tube is provided with a water outlet pipe frame 21, and the described water outlet pipe frame is provided with a hanging ring 22, and the described spray tube includes a rotating spray tube 1-1 and a fixed spray tube 1-2. Spray barrel is arranged on the front side of described fixed spray barrel through bearing 17, and described annular spray pipe is arranged on the front end of described rotating spray barrel, and described water outlet pipe passes through described hanging ring and is communicated with described annular spray pipe, so The fan is arranged inside the fixed spray cylinder, and the rotating spray cylinder rotates in a reciprocating cycle under the action of the driving mechanism. The spray barrel is fixed, and the atomized chemical liquid is sprayed forward in a straight line from multiple nozzles. The liquid sprayed out in a straight line can only contact and react with the gun smoke particles w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com