Front-loading-type Washing Machine

A drum-type washing machine, washing machine shell technology, applied to other washing machines, washing machines with containers, washing devices, etc., can solve the problem of eccentric load, the direction in which the shock absorption force of the shock absorber works is limited, and the swing of the water tank unit cannot be prevented. sports, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, this invention is not limited to this embodiment.

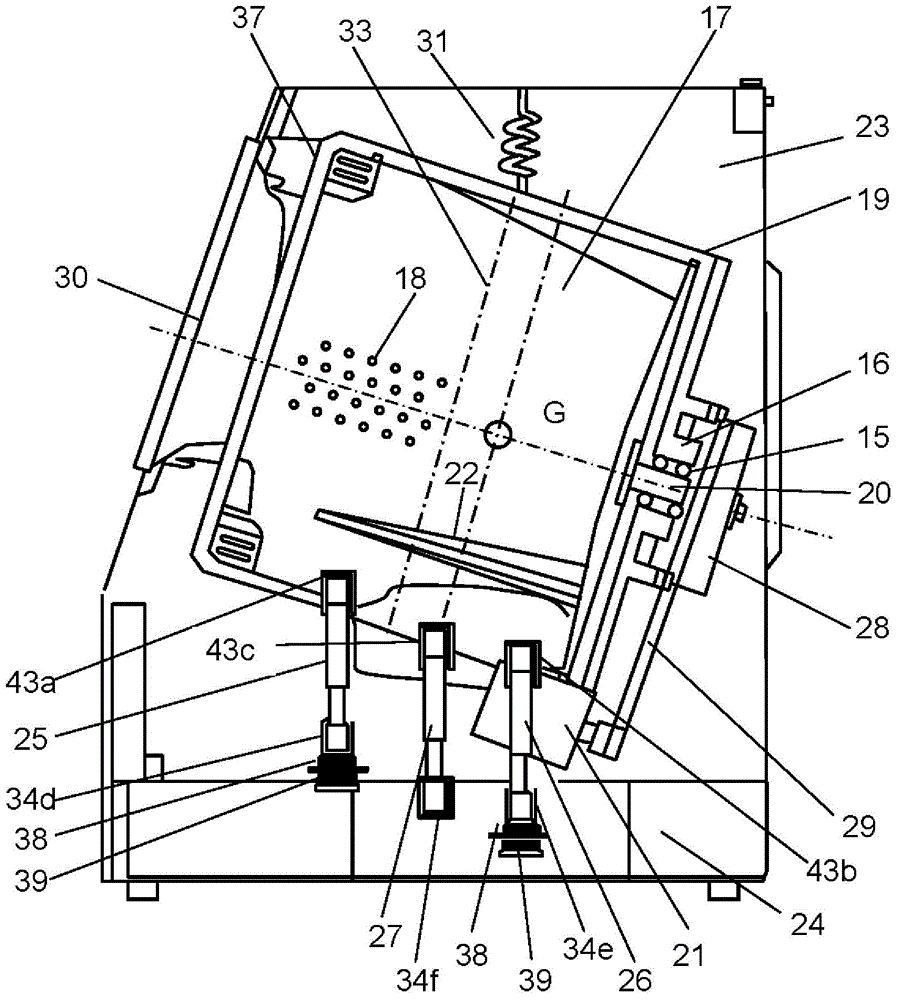

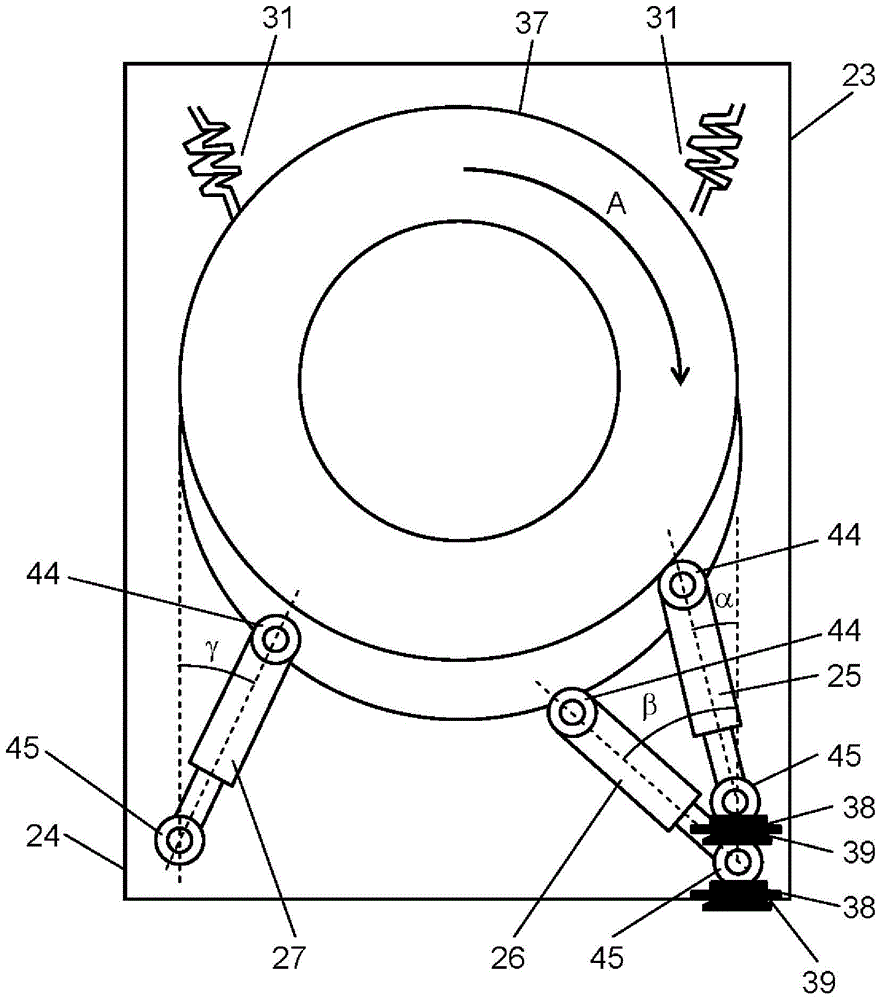

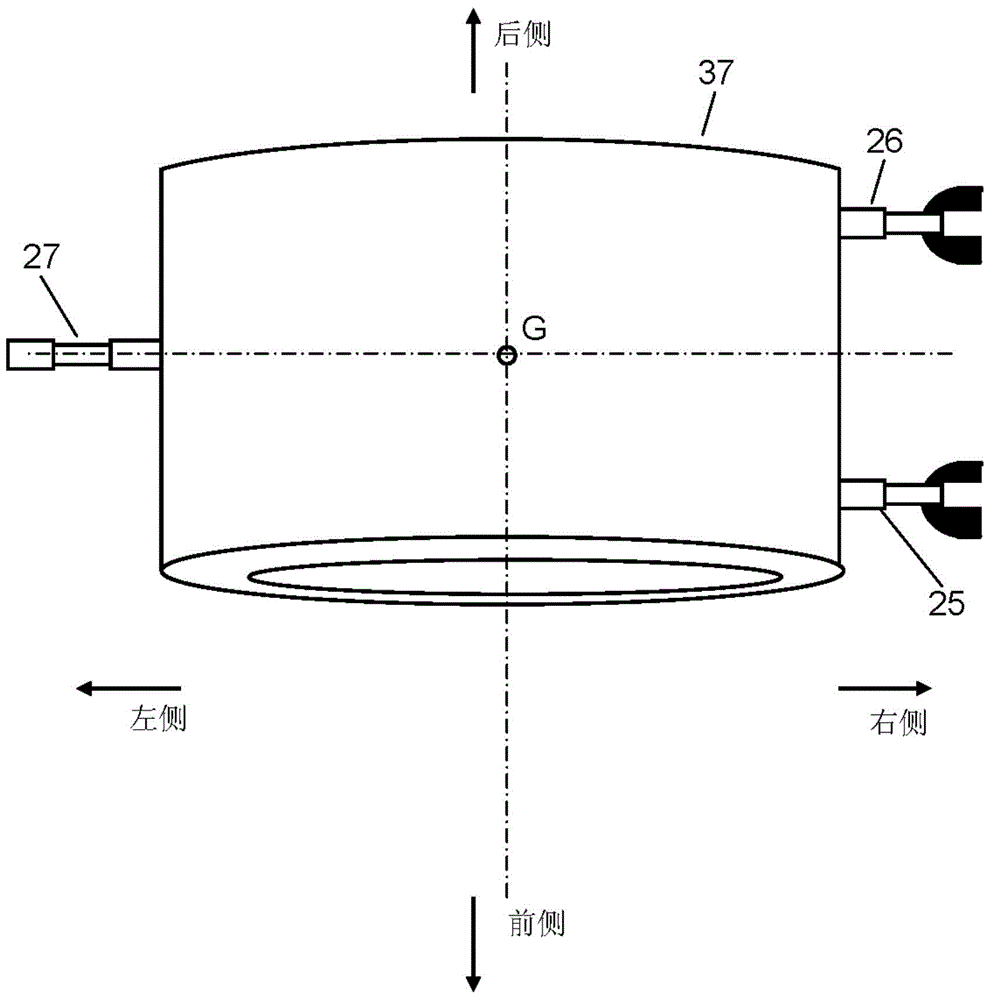

[0022] figure 1 It is a longitudinal sectional view of the front-loading-type washing machine in embodiment of this invention. figure 2 is the internal front view of the front-loading washing machine. image 3 It is a figure which looked at the inside of this front-loading washing machine from above. Figure 4 It is a longitudinal sectional view of the anti-vibration damper and the casing connection part of this front-loading-type washing machine. Figure 5 It is a vertical cross-sectional view showing another structure of the anti-vibration damper and the case connecting portion of the front-loading-type washing machine.

[0023] exist figure 1 , figure 2 as well as image 3 Among them, the rotary drum 17 is formed in a bottomed cylindrical shape, and is rotatably arranged in the water tank 19 vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com