Vibration well cementation device and vibration well cementation method

A technology of cementing and oscillator, which is applied in the field of oil drilling and cementing, can solve the problems of limited range of vibration influence, influence on spud, high power, etc., and achieve the effect of simple AC wiring at the well site, low operating cost, and low energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

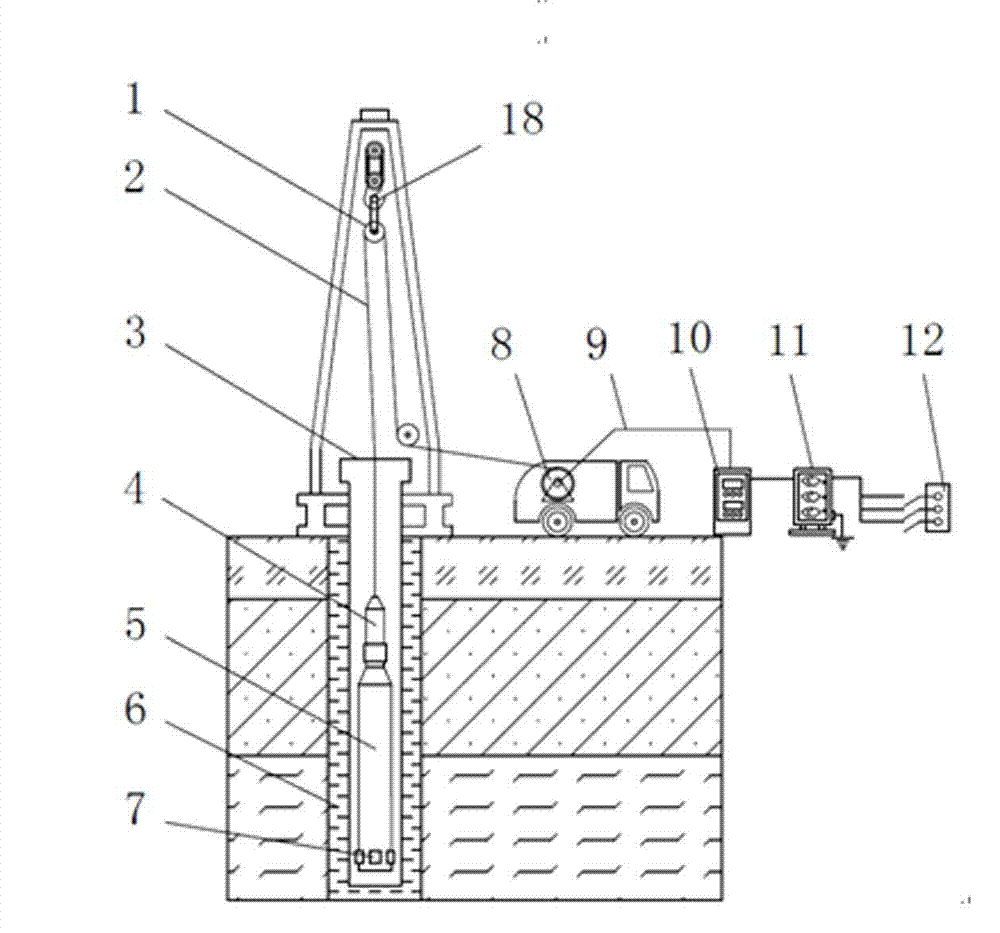

[0039] Refer to the attached figure 1 And attached figure 2 , in the vibration cementing device of the present invention, the ground uses a logging vehicle to load the cable 2, winch 8, frequency converter 10 and transformer 11, and the logging vehicle is equipped with a winch slip ring for transmitting alternating current. The cable 2 is a seven-core steel cable for well logging, and is wound on the well logging vehicle-mounted winch 8. One end of the cable is connected to the well logging horse head 4, and the other end is connected to the output end of the frequency converter 10 through the slip ring of the well logging winch. The input end of the frequency converter 10 is connected to the output end of the transformer 11, and the input end of the transformer 11 is connected to the 380V three-phase AC power supply at the well site.

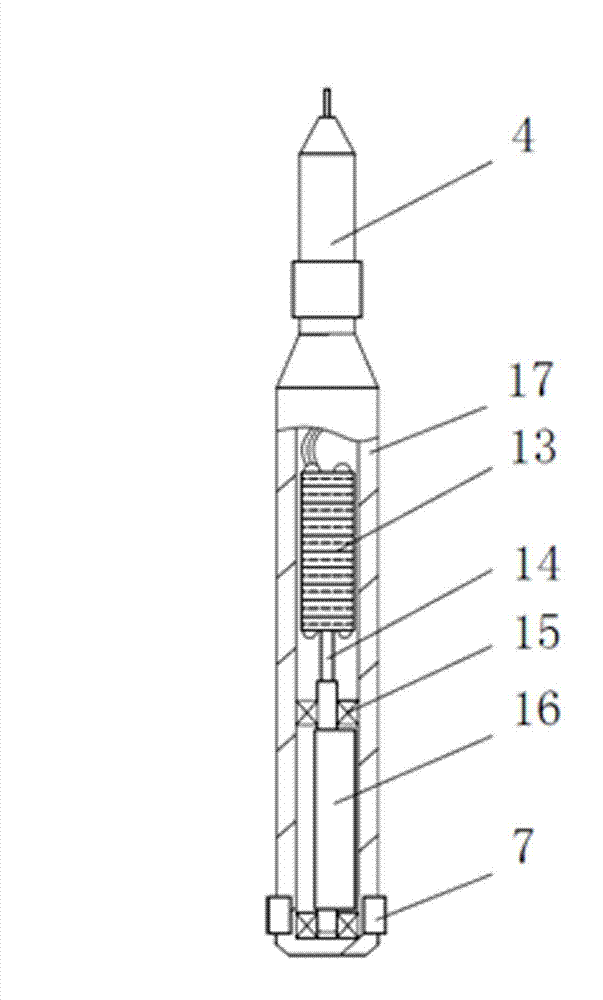

[0040] The upper end of the oscillator 5 is connected with the tap 4, and the alternating current is transmitted through the pin of the tap....

Embodiment 2

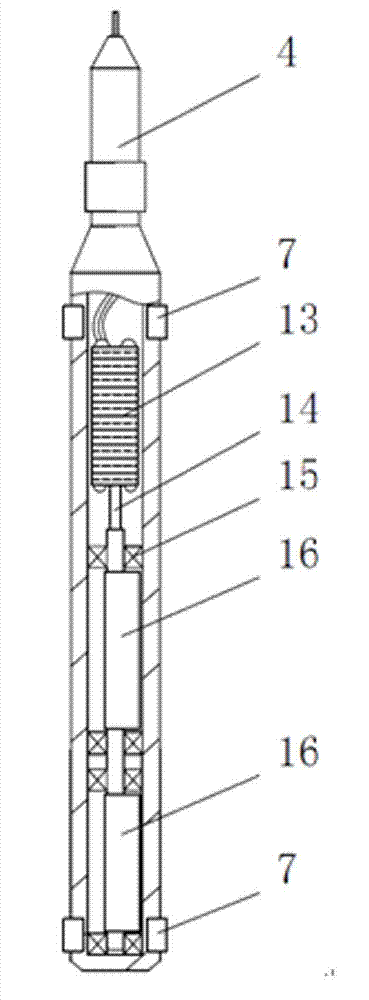

[0050] Refer to attached image 3 Compared with Embodiment 1, the eccentric block 16 of the vibratory cementing device is changed to two axially connected in series, and each is fixed in the pressure-resistant cavity 17 through a pair of bearings; the shell at the upper end of the oscillator 5 is also circumferentially embedded There are 3 to 8 rubber blocks 7, preferably 4, which can not only ensure that the low end of the oscillator 5 does not directly collide with metal, but also maintain a large enough flow channel between the rubber blocks, which is beneficial to Increase the lifting speed in the casing.

[0051] The length and quantity of the eccentric mass 16 can also be increased to increase the vibration force. The number of eccentric blocks 16 is changed from one to two in series, and the number of bearings is multiplied. Compared with a single eccentric load with the same total length, the load of a single bearing can be reduced and the life of the bearing can be i...

Embodiment 3

[0053] Compared with Embodiment 1, the cable 2 is directly fixedly connected to the oscillator 5 , the cable 2 is a steel cable with a load-bearing steel wire on the outside, and the steel wire is fixed on the top of the pressure chamber 17 by welding or riveting. The wires in the cable 2 are connected to the motor 13, and the motor 13 is fixed in the pressure chamber 17 with an interference fit. The large hook 18 on the derrick at the wellhead lifts the pulley 1 as the sky pulley, and cooperates with the ground pulley in the well logging engineering to better ensure the stability of the cable 2.

[0054] The other end of the cable 2 is directly connected to the output end of the transformer 11 through the winch slip ring. The total length of the cable 2 is 6 kilometers and the total resistance is 150Ω. The input end of the transformer 11 is connected to the power frequency 380V three-phase AC power supply at the well site, and the rated operating voltage of the motor is 380V....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com