Multistage chemical material screening and treatment device

A processing device and technology for chemical raw materials, applied in the field of multi-stage chemical raw material screening and processing devices, can solve problems such as low screening degree, reduced production efficiency, and raw material mixing, so as to improve screening efficiency, improve screening efficiency, and avoid bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

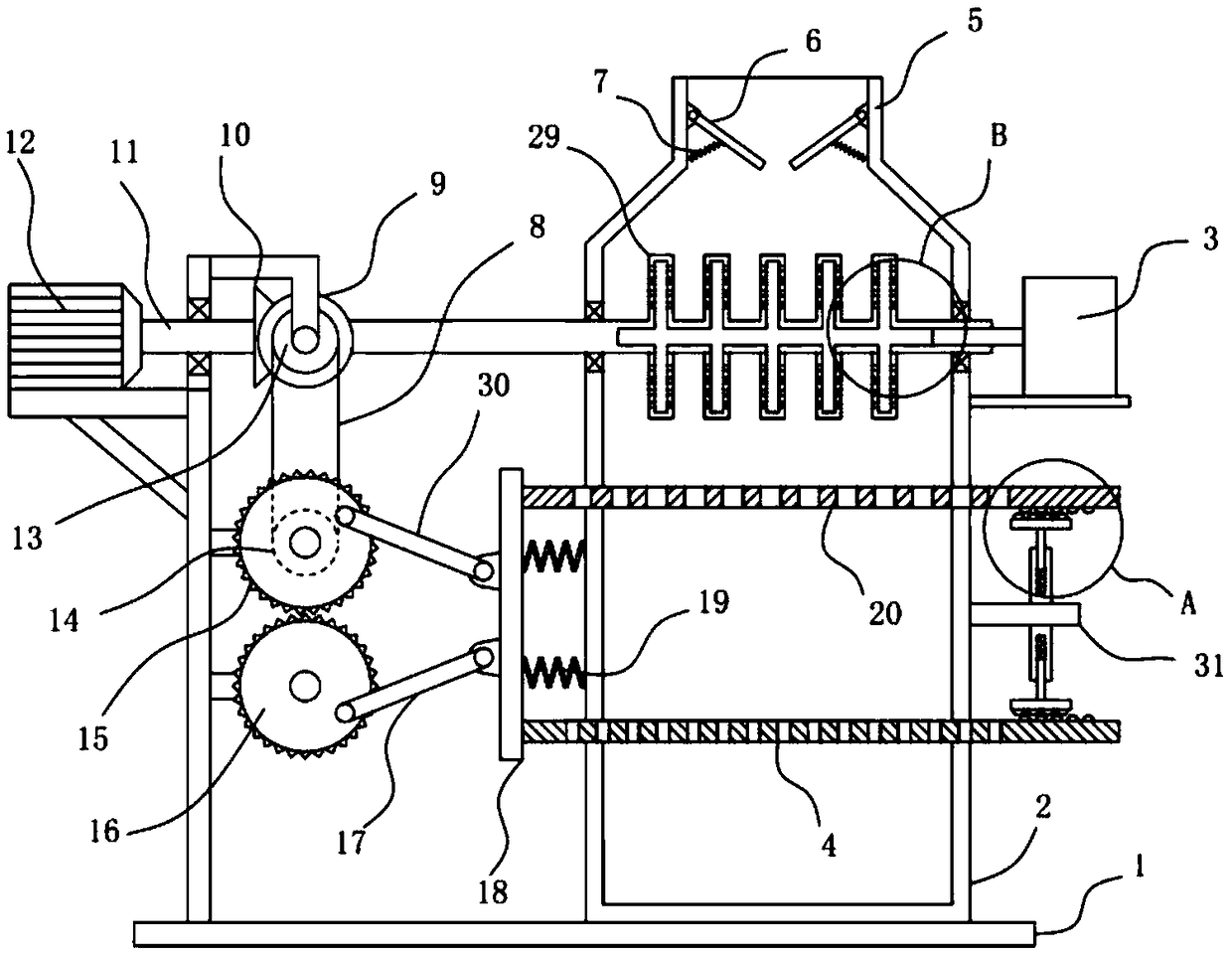

[0021] see Figure 1-3 , a multi-stage chemical raw material screening processing device, comprising a carrier frame 1, a screening bucket 2 is fixedly installed on the carrier frame 1, a feed pipe 5 is installed on the upper end of the screening bucket 2, and a feed pipe 5 is fixedly installed on the carrier frame 1 Drive motor 12, the output shaft of drive motor 12 is fixedly installed with drive shaft 11 coaxially. The provided drive motor 12 is used as the power source of the device for driving the drive shaft 11 to rotate.

[0022] The surface of the drive shaft 11 is sleeved and fixed with a driving bevel gear 10, the driving bevel gear 10 is meshed with a driven bevel gear 9, the driven bevel gear 9 is coaxially fixed with a driving pulley 13, and the side wall of the bearing frame 1 is rotatable. A driving gear 15 and a driven gear 16 meshingly connected are provided, and the driving gear 15 is coaxially fixed with a driven pulley 14 connected to the driving pulley 13...

Embodiment 2

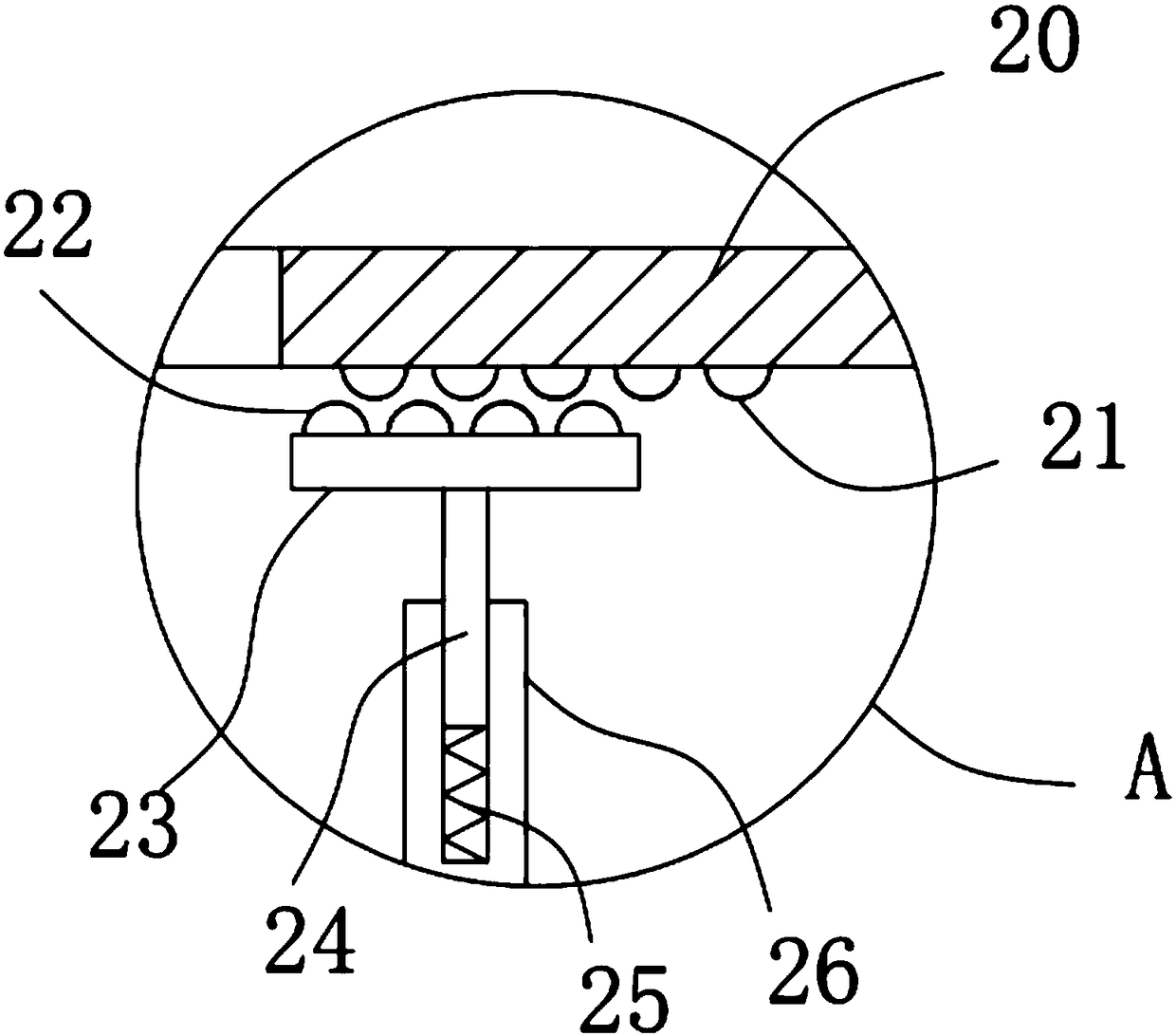

[0026] On the basis of Embodiment 1, in addition, an extension plate 31 is fixedly installed on the right side of the screening bucket 2, and the upper and lower side walls of the extension plate 31 are respectively vertically fixed with a sleeve 26, and the sleeve 26 is slidingly provided with a slide bar 24 and a The sliding bar 24 is fixedly connected to the longitudinal return spring 25, and the end of the sliding bar 24 away from the casing 26 is fixed with a horizontal plate 23, and the horizontal plate 23 is fixed with a bump II22. The bump I21 abutting against the bump II22 is fixed on the surface.

[0027] When the first sieve plate 20 and the second sieve plate 4 move laterally, the protrusion I21 provided on the first sieve plate 20 and the second sieve plate 4 and the protrusion II22 on the horizontal plate 23 produce a relative displacement, and the longitudinal return spring Under the action of the elasticity of 25, the sliding bar 24 drives the horizontal plate ...

Embodiment 3

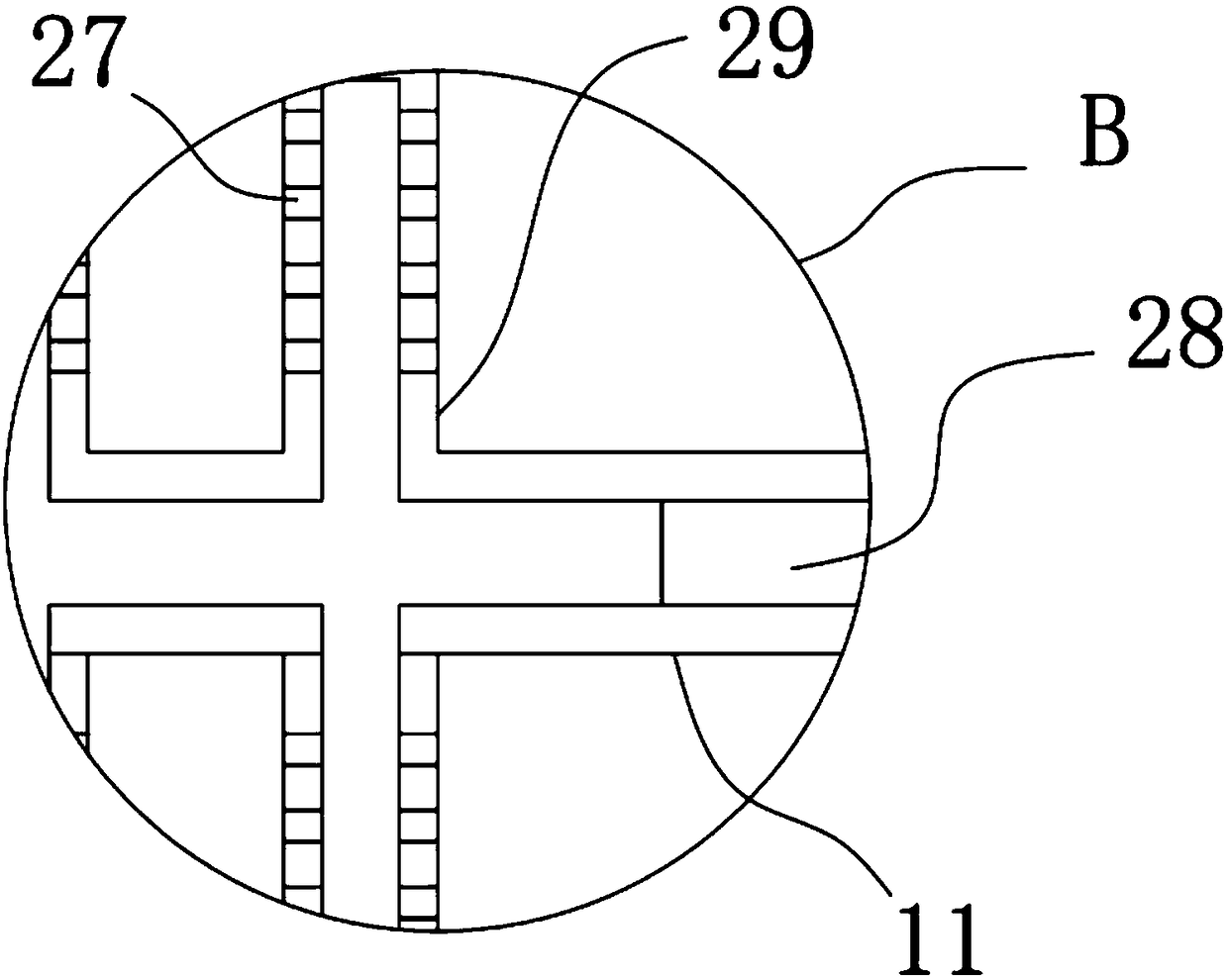

[0029] On the basis of embodiment 2, in addition, sieve barrel 2 right side walls are fixed with hot air blower 3, and the outlet end of hot air blower 3 is communicated with and installed with air intake pipe 28, and driving shaft 11 inside is provided with cavity, and air intake pipe 28 extends to Inside the cavity, the surface of the driving shaft 11 is evenly fixed with several rotating tubes 29 communicating with the cavity of the intake pipe 28, and the surface of the rotating tube 29 is evenly provided with several air outlet holes 27.

[0030] The hot air blower 3 injects the hot air generated into the cavity of the drive shaft 11 through the air inlet pipe 28, and the rotation of the drive shaft 11 drives the rotation of the rotating tube 29, and the rotating tube 29 pairs of materials that fall into the screening bucket 2 from the feed pipe 5 The chemical raw materials are broken up, which promotes the dispersion of the chemical raw materials. At the same time, the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com