Valve body assembling machine

A technology for assembly machines and valve bodies, which is applied to the surface coating liquid device, mechanical equipment, material gluing, etc., can solve the problems of uncontrollable production quality and low assembly efficiency, so as to improve production efficiency and pass the one-way valve High efficiency, automatic glue application, and the effect of firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

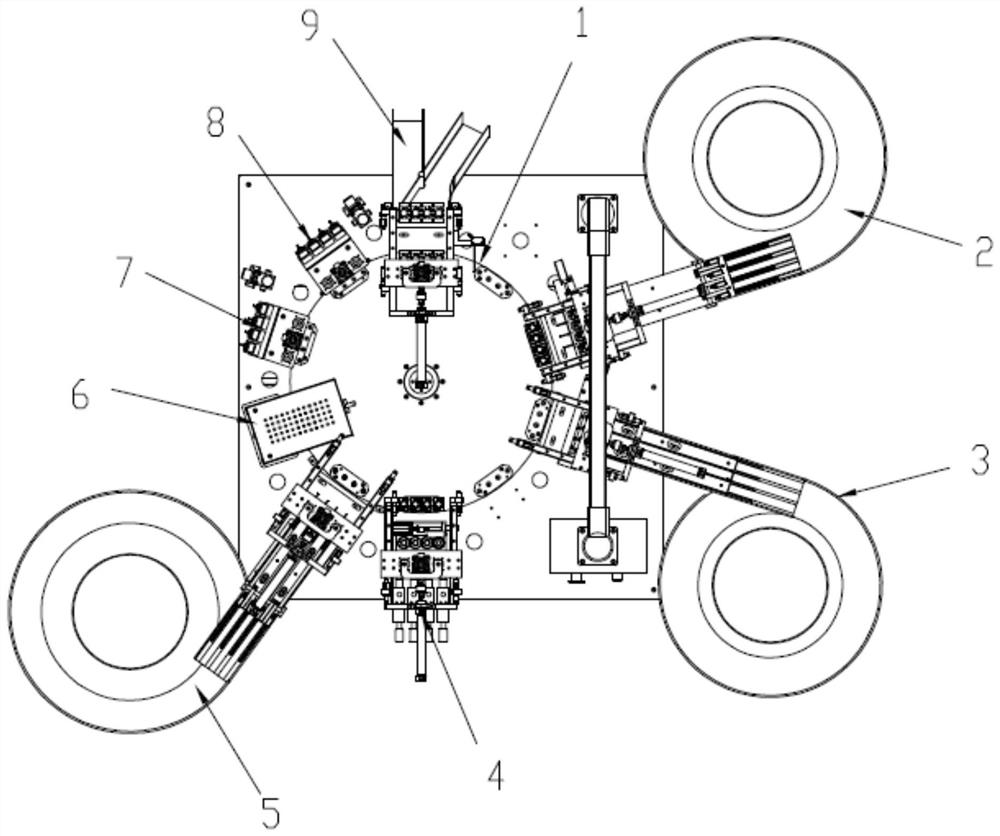

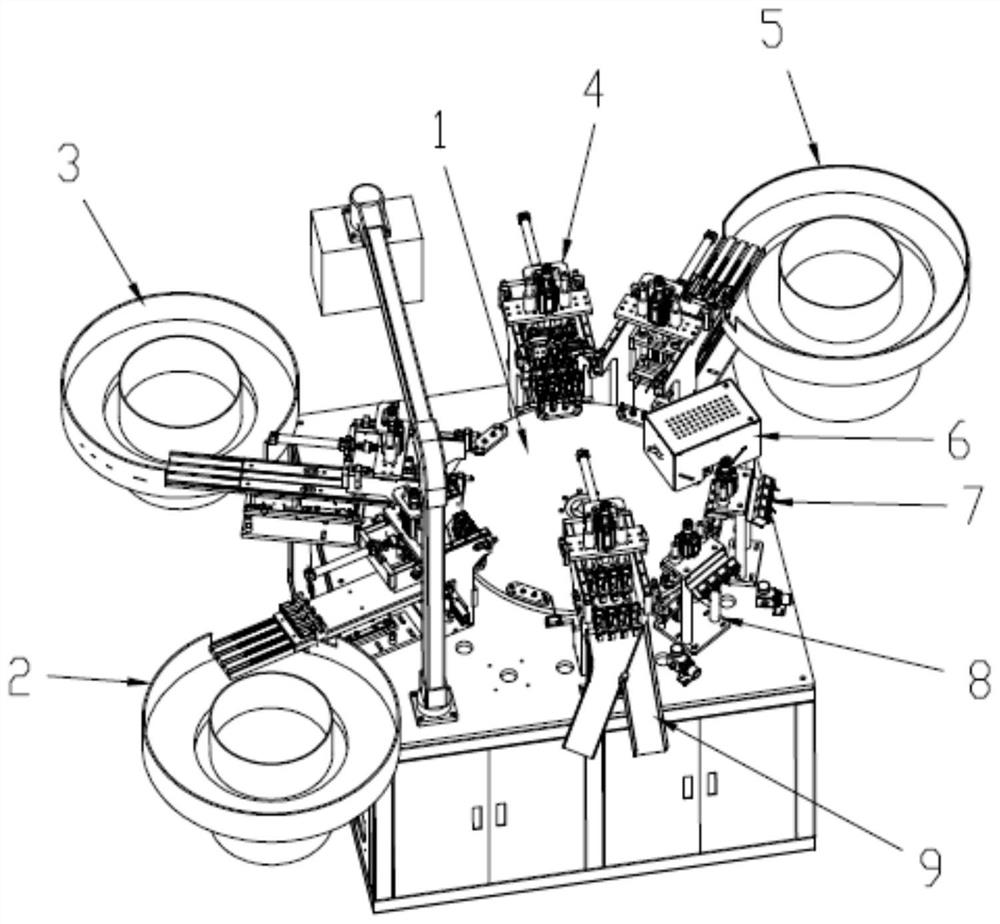

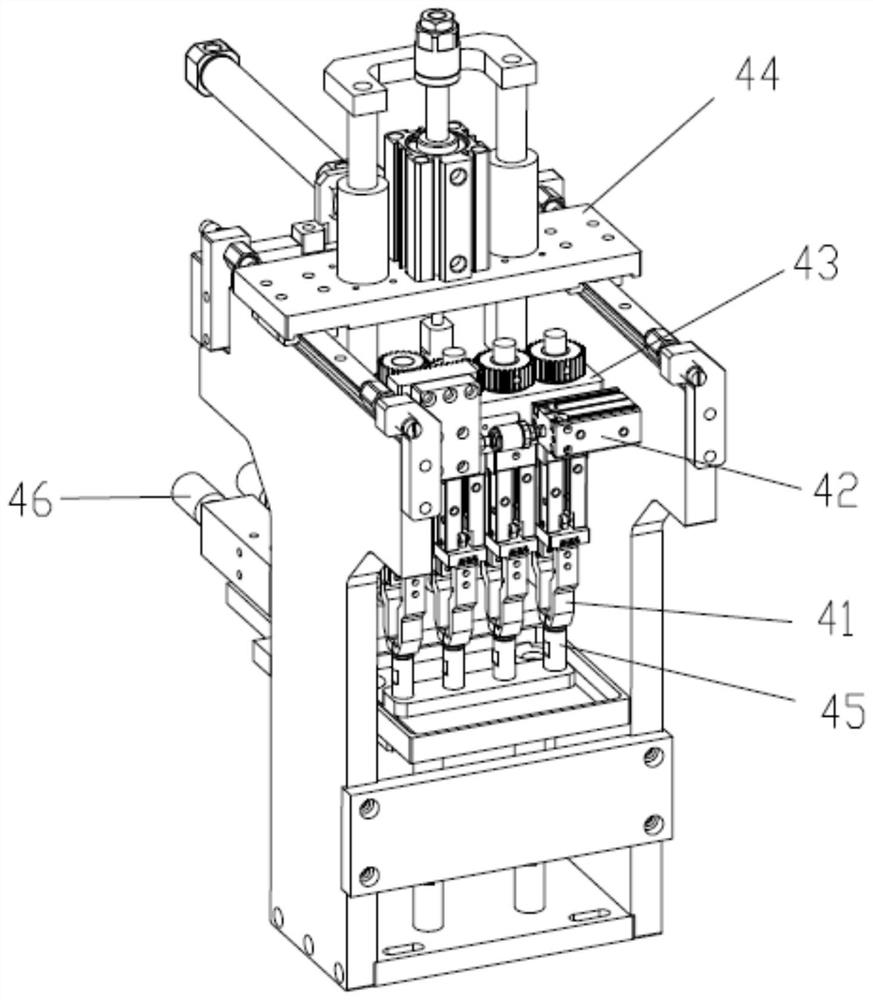

[0049] see Figure 1 to Figure 13 , a valve body assembly machine of the present invention, comprising a frame and a turntable 1 mounted on the frame for rotation, and also including a first feeding assembly 2, a gluing device 4, The third feeding device 5, the drying device 6 and the feeding device 9, the turntable 1 is provided with several jigs 11, and the jigs 11 are used to carry the first material 101 and the first material 101 from the first feeding assembly 2 thereof. The third material 103 from its third feeding device 5, the gluing device 4 includes a jaw assembly 41, a rotating drive member 42, a mounting plate 43, a transfer device 44 and a glue tank 45;

[0050] The glue tank 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com