A kind of anti-corrosion technology of sticking anode inside the high corrosion section under the oil pump

A technology of oil well pump and anode, which is applied in the direction of wellbore/well components, earthwork drilling and production, etc. It can solve problems such as the solution to the oil pipe that has not been mentioned, achieve rich anti-corrosion technical means, avoid the risk of pipe sticking, and realize the conductive connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

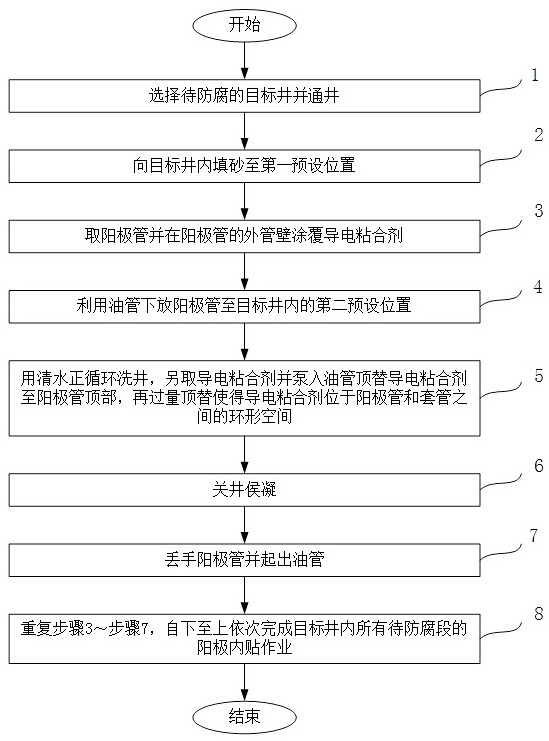

[0051] The first embodiment of the present invention relates to an anti-corrosion process for sticking anodes in a high-corrosion section under an oil pump, including the following steps:

[0052] Step 1. Select the target well to be anticorrosion and pass the well;

[0053] Step 2. Fill the target well with sand to the first preset position;

[0054] Step 3. Take the anode tube and coat the outer tube wall of the anode tube with conductive adhesive;

[0055] Step 4. Using the tubing to lower the anode tube to the second preset position in the target well;

[0056] Step 5. Rinse the well with clean water in positive circulation, take another conductive adhesive and pump it into the oil pipe to replace the conductive adhesive to the top of the anode tube, and then excessively replace the conductive adhesive so that the conductive adhesive is located in the annular space between the anode tube and the casing;

[0057] Step 6. Shut in the well;

[0058] Step 7. Discard the ano...

no. 2 approach

[0065] The present embodiment relates to the anti-corrosion process of sticking anodes in the high corrosion section under the oil well pump, including the following steps:

[0066] Step 1. Select the target well to be anticorrosion and pass the well;

[0067] Step 2. Fill the target well with sand to the first preset position;

[0068] Step 3. Take the anode tube and coat the outer tube wall of the anode tube with a conductive adhesive with a coating thickness of 3 to 5 mm;

[0069] Step 4. Using the tubing to lower the anode tube to the second preset position in the target well;

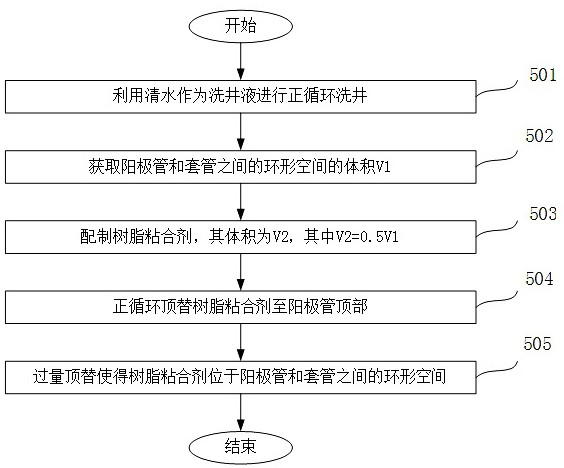

[0070] Step 5. Rinse the well with clean water in positive circulation, take another conductive adhesive and pump it into the oil pipe to replace the conductive adhesive to the top of the anode tube, and then excessively replace the conductive adhesive so that the conductive adhesive is located in the annular space between the anode tube and the casing, like figure 2 shown, including:

[0071]...

no. 3 approach

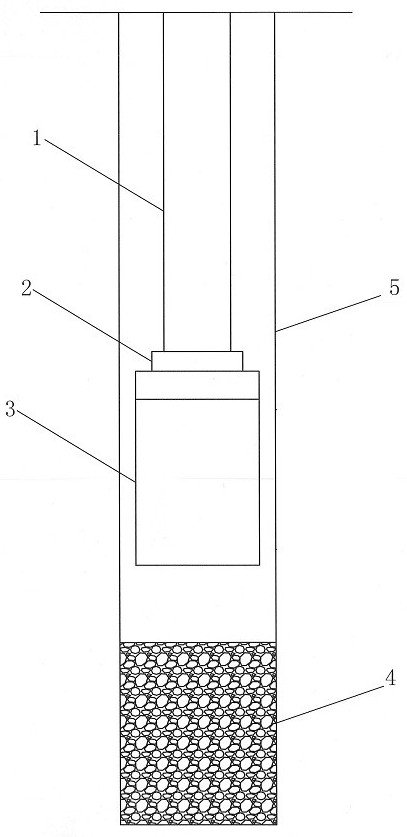

[0093] According to the anti-corrosion process of sticking anodes in the high-corrosion section under the oil pump provided by the second embodiment, the anti-corrosion of Zhen X well is implemented:

[0094] The oil pump of the well is 350m above the perforation section, and 7 anode tubes are run at a distance of 50m;

[0095] Anode tube size: outer diameter 112mm, inner diameter 98mm, length 5m, the molding process is casting.

[0096] The current efficiency of the anode tube measured indoors is 40%.

[0097] Resin binder: 100 parts E40 epoxy resin, 10 parts m-phenylenediamine, 17 parts liquid nitrile-40, 1 part resorcinol, 20 parts silver powder, 3 parts acetylene carbon black (purity 99%), liquid 1 part of nitrile rubber and 50 parts of aluminum powder, each component is added to the reaction vessel according to the above proportions, heated and stirred evenly to obtain a resin adhesive.

[0098] The shear strength of solidified bonded steel pipe and aluminum alloy is 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com