High-pressure-bearing temporary plugging agent

A temporary plugging agent, high pressure technology, applied in the field of plugging agent, can solve the problems of long cement injection process, high cost, high risk of drill plug sticking, etc., achieve controllable curing time, low cost, avoid Effect of stuck pipe risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

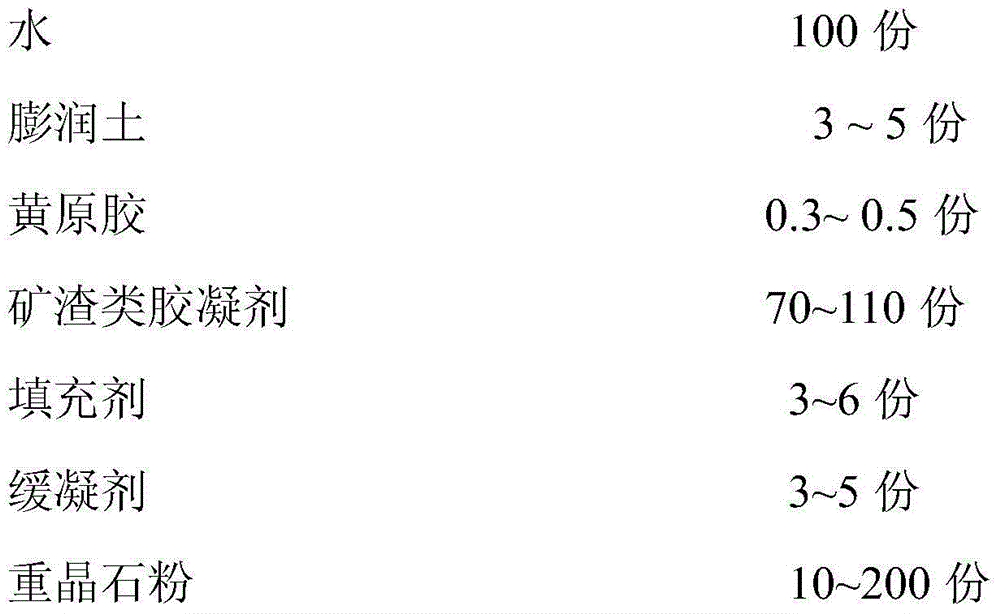

Embodiment 1

[0008] Embodiment 1: Weigh 100 parts of water, 3 parts of bentonite, 0.3 part of xanthan gum, 3 parts of retarder, 70 parts of slag gelling agent, 3 parts of filler and 100 parts of barite powder, add in the mud tank, Stir for 30 minutes to obtain a high-pressure temporary plugging agent.

[0009] The tested high-pressure temporary plugging agent has a density ranging from 1.4 to 1.9 g / cm3 and an applicable temperature range of 70°C to 130°C.

Embodiment 2

[0010] Embodiment 2: Weigh 100 parts of water, 5 parts of bentonite, 0.5 part of xanthan gum, 5 parts of retarder, 110 parts of slag gelling agent, 6 parts of filler and 200 parts of barite powder, add in the mud tank, Stir for 40 minutes to obtain a high-pressure temporary plugging agent.

[0011] The tested high-pressure temporary plugging agent has a density ranging from 1.4 to 1.9 g / cm3 and an applicable temperature range of 70°C to 130°C.

Embodiment 3

[0012] Embodiment 3: Weigh 100 parts of water, 5 parts of bentonite, 0.4 part of xanthan gum, 4 parts of retarder, 100 parts of slag gelling agent, 5 parts of filler and 150 parts of barite powder, add in the mud tank, Stir for 30 minutes to obtain a high-pressure temporary plugging agent.

[0013] The tested high-pressure temporary plugging agent has a density ranging from 1.4 to 1.9 g / cm3 and an applicable temperature range of 70°C to 130°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com