Multi-formation fracturing device and process of release tubular column

A multi-layer fracturing technology, applied in the direction of drill pipe, casing, production fluid, etc., can solve the problems of high risk of sand stuck and difficult removal of pipe string, so as to reduce the risk of sand plugging and easy drill sticking , high working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

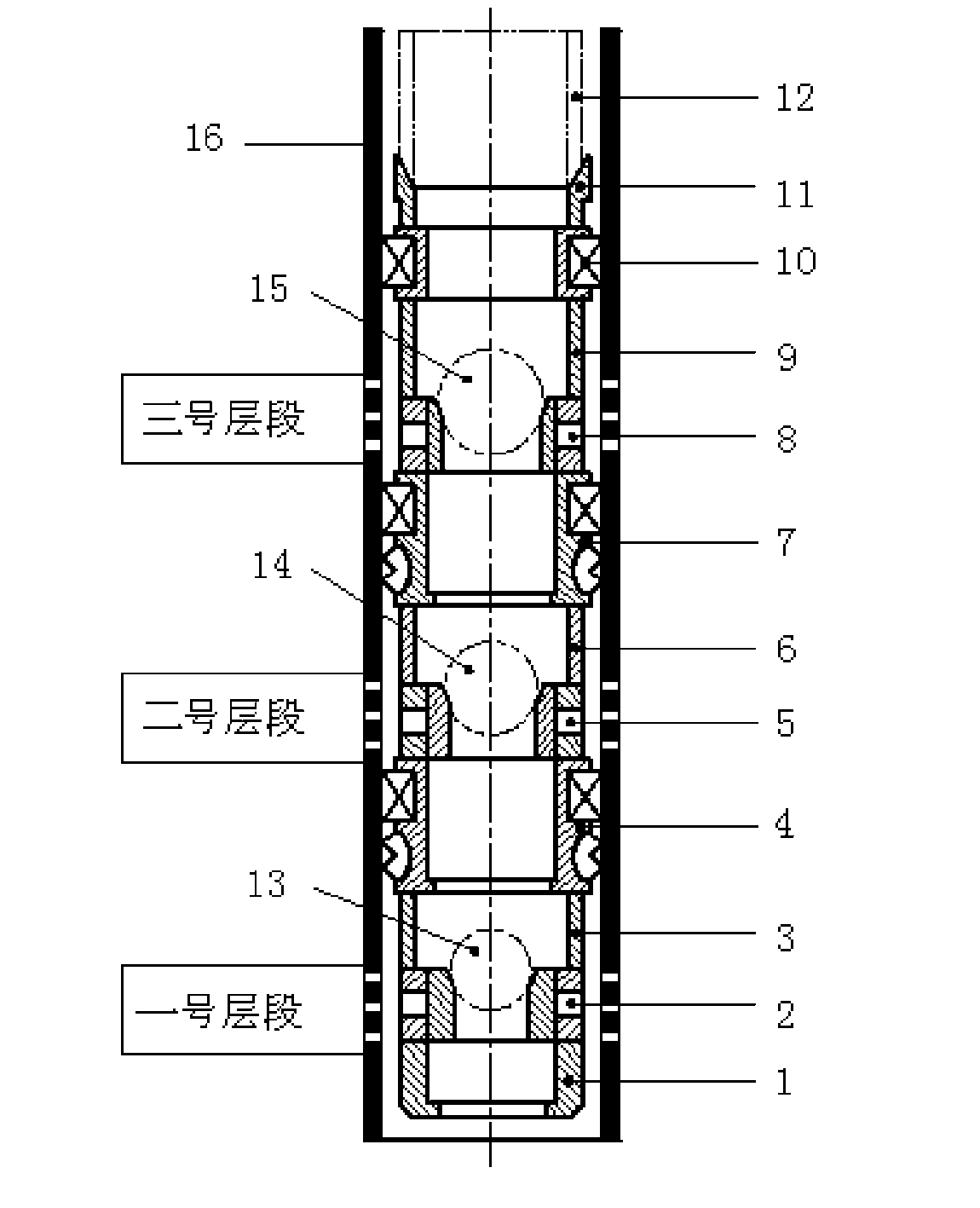

[0032] Example 1 provides an example of fracturing in three layers in a fracturing string.

[0033] Such as figure 1 As shown, it includes sliding sleeve seat 1, first-stage sand blaster 2, first-stage oil pipe 3, first-stage packer 4, second-stage sand blaster 5, second-stage oil pipe 6, and second-stage packing 7, the third-stage sand blaster 8, the third-stage oil pipe 9, the third-stage packer 10, the hand-off joint 11, and the oil delivery pipe 12. The first-stage sand blaster 2 is threadedly connected with the lowermost sliding sleeve seat 1, and is seated on the sliding sleeve seat 1; the first-stage sand blaster 2 connects with the first-stage packer 4 through the first-stage oil pipe 3 in the middle The connection forms a one-layer fracturing string. The second-stage sand blaster 5 is connected with the first-stage packer 4 through threads, and is seated on the first-stage packer 4. The second-stage sand blaster 5 passes through the second-stage oil pipe 6 and conne...

Embodiment 2

[0047] Embodiment 2 gives an embodiment in which the fracturing string has four layers.

[0048] Same as Example 1, at least including sliding sleeve seat 1, first-stage sand blaster 2, first-stage oil pipe 3, first-stage packer 4, second-stage sand blaster 5, second-stage oil pipe 6, first-stage Secondary packer 7, third-stage sand blaster 8, third-stage oil pipe 9, third-stage packer 10, hand-off joint 11, and oil delivery pipe 12. Add the fourth sand blaster, the fourth tubing, and the fourth packer on the basis of the above, and the first-stage sand blaster 2 is threadedly connected with the lowermost sliding sleeve seat 1 and is seated on the sliding sleeve seat 1; The first-stage sand blaster 2 is connected with the first-stage packer 4 through the intermediate first-stage tubing 3 to form a layer of fracturing string. The second-stage sand blaster 5 is connected with the first-stage packer 4 through threads, and is seated on the first-stage packer 4. The second-stage s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com