A prefabricated slab for prefabricated buildings, a connection method between the prefabricated slab and the beam, and a construction method

A technology of construction method and connection method, which is applied in the directions of buildings, building components, building structures, etc., can solve the problems of difficult occlusion of adjacent prefabricated panels, difficulty in ensuring construction quality, and difficulty in pin positioning, so as to achieve overall firmness, reduce Concrete dosage and excellent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

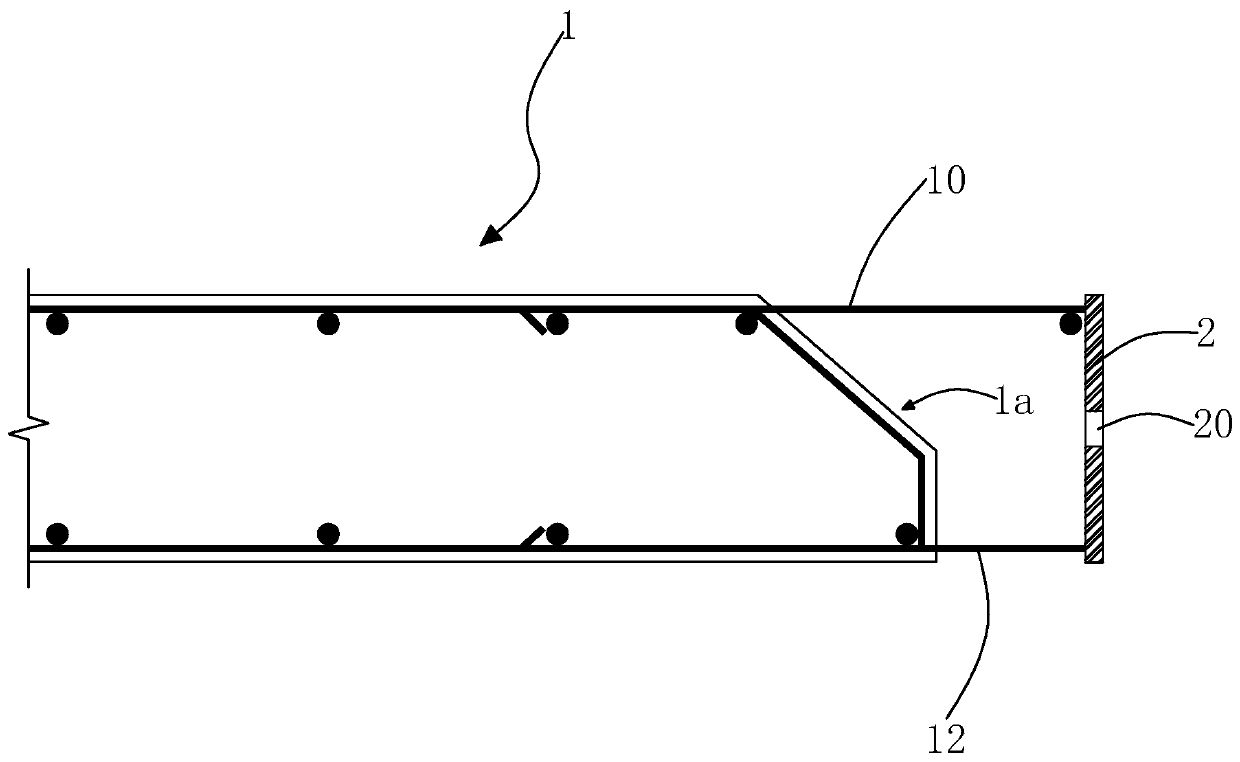

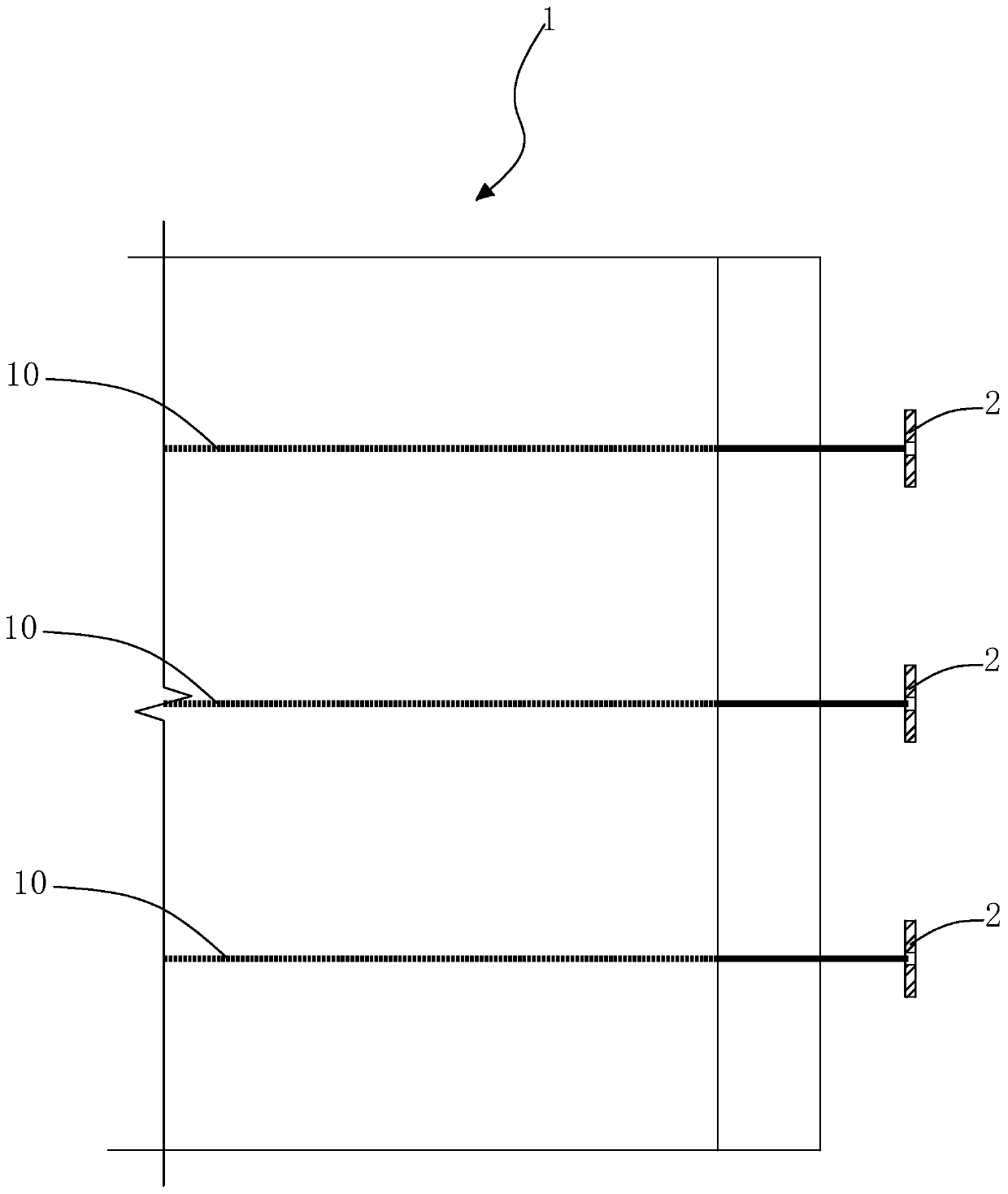

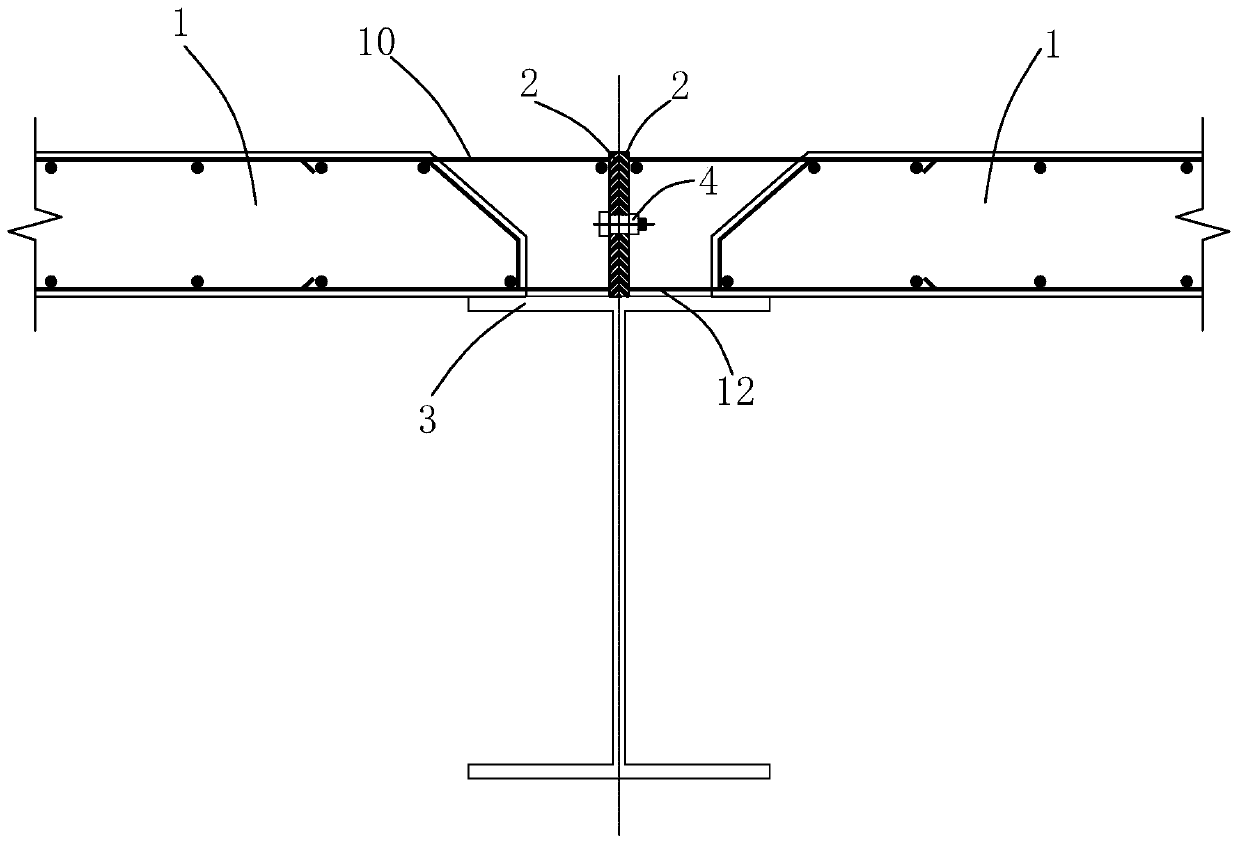

[0037] The invention provides a prefabricated panel for prefabricated buildings, such as figure 1 with figure 2 As shown, the prefabricated slab body 1 is included, and the prefabricated slab body 1 has plate gluten 10 and slab bottom rib 12, and the slab gluten 10, slab bottom rib 12 and other longitudinally arranged steel bars are welded to form a steel skeleton, defining the prefabricated slab body 1 The end face connected to the beam is the joint surface 1a, and the surface of the joint surface 1a is roughened to make it a rough surface with a concave-convex difference of not less than 6mm, so as to increase the bonding force of the concrete poured in the edge seam of the slab. A plurality of panel gluten bars 10 and a plurality of panel bottom ribs 12 in the prefabricated panel body 1 all extend to the outside of the joint surface 1a, and there are a plurality of connecting plates 2 arranged at intervals along the length direction of the joint surface outside the joint s...

Embodiment 2

[0045] The present invention also provides a connection method and construction method between prefabricated slabs and beams, refer to Figure 1-Figure 8 , including the following steps,

[0046] S1. Beams and prefabricated slabs are provided, wherein the prefabricated slab is any one of the prefabricated slabs described in Embodiment 1, and the bearing surface of the beam 3 has a shear connector 6;

[0047] S2. Hoist the prefabricated slab. After the prefabricated slab is hoisted in place, use bolts on site to lock the connecting plates on the prefabricated slabs on both sides of the beam (the length of the end of the prefabricated slab resting on the beam should not be less than 30mm, and the bolts should be M16, and Meet the structural requirements of "Code for Design of Concrete" GB 50010, "Code for Design of Steel Structure" GB 50017 and other relevant specifications);

[0048] S3. Pouring concrete strips, pouring self-compacting concrete strips at the boundary joints of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com