Silicon-carbon negative electrode material for lithium ion battery and preparation method

A technology of lithium-ion batteries and negative electrode materials, applied in the direction of battery electrodes, nanotechnology for materials and surface science, negative electrodes, etc., can solve the problems of high specific capacity batteries, volume changes, volume expansion, etc., and achieve excellent Cycling performance, simple preparation process, and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

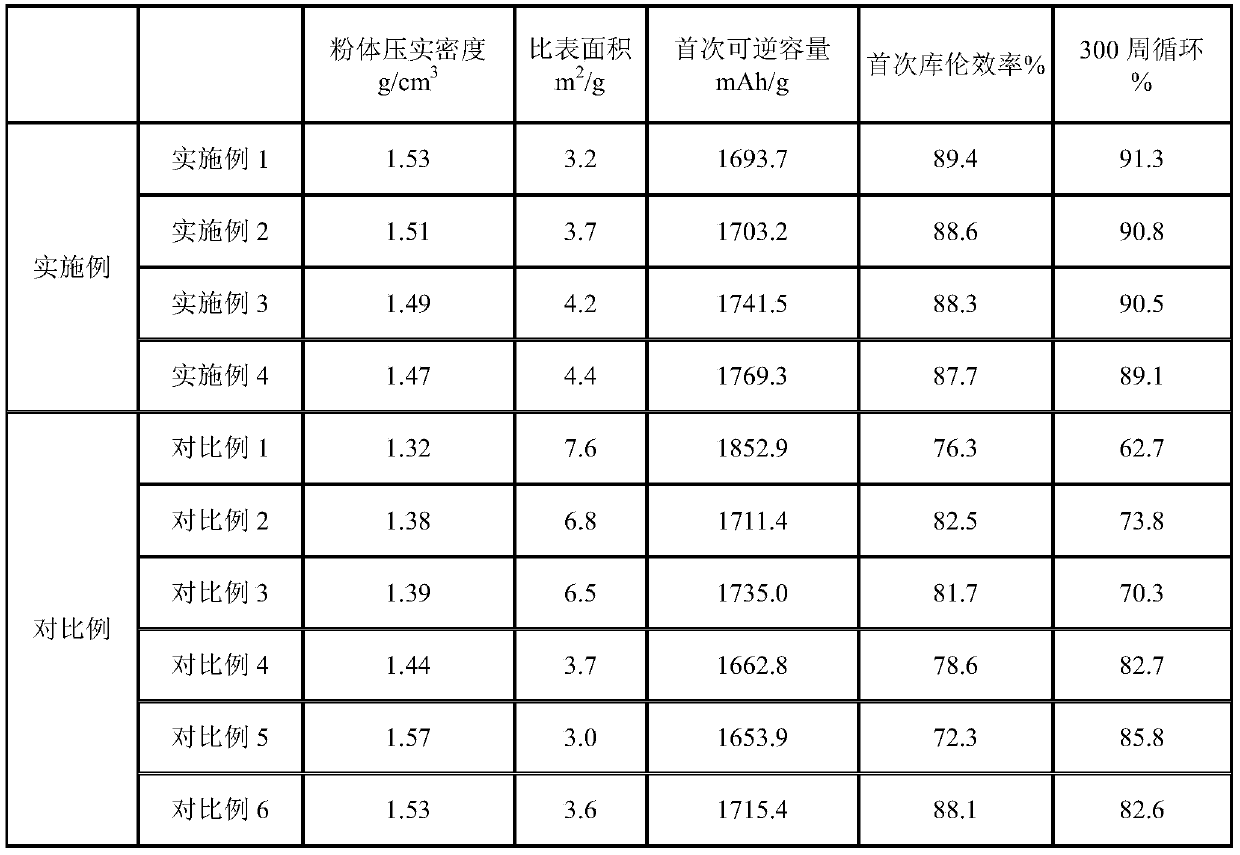

Embodiment 1

[0032] A method for preparing a silicon-carbon negative electrode material for a lithium-ion battery, comprising the steps of:

[0033] (1) A dispersant is added to the single-walled carbon nanotube suspension, wherein the single-walled carbon nanotube is an N-methylpyrrolidone system with a diameter of 5-10nm, a length of 30-100nm, and a mass of 100g. The mass ratio of walled carbon nanotubes in the suspension is 0.1%, the dispersant is sodium lauryl sulfate, and the quality is 5g, and then the suspension is diluted to the concentration of single-walled carbon nanotubes with N-methylpyrrolidone. The mass content is 0.01%. After stirring evenly, add domestic asphalt. The softening point of the asphalt is 230°C, the carbon residue rate is 63%, and the mass is 500g. Start ultrasonic dispersion. The ultrasonic frequency is 100KHz and the ultrasonic time is 5h. Stir slowly. After drying, silicon carbon negative electrode material precursor 1 is obtained;

[0034] (2) Add the nega...

Embodiment 2

[0038] A method for preparing a silicon-carbon negative electrode material for a lithium-ion battery, comprising the steps of:

[0039] (1) A dispersant is added to the single-walled carbon nanotube suspension, wherein the single-walled carbon nanotube is an N-methylpyrrolidone system with a diameter of 10-20nm, a length of 100-500nm, and a mass of 100g. The mass ratio of walled carbon nanotubes in the suspension is 0.1%, the dispersant is polyacrylamide, and the quality is 5g, and then the suspension is diluted to the mass content of single-walled carbon nanotubes with N-methylpyrrolidone. 0.03%, after stirring evenly, add phenolic resin, the softening point of phenolic resin is 180°C, the carbon residue rate is 51%, the mass is 600g, start ultrasonic dispersion, ultrasonic frequency is 80KHz, ultrasonic time is 3h, stir slowly, after drying Obtain silicon carbon negative electrode material precursor 1;

[0040] (2) Add the negative electrode material precursor 1 in the step...

Embodiment 3

[0044] A method for preparing a silicon-carbon negative electrode material for a lithium-ion battery, comprising the steps of:

[0045] (1) Add a dispersant to the single-walled carbon nanotube suspension, wherein the single-walled carbon nanotube is a water system, the diameter of the tube is 5-10nm, the length of the tube is 30-100nm, and the quality is 100g. The mass ratio in the suspension is 0.1%, the dispersant is polyvinylpyrrolidone, the mass is 5g, and then the suspension is diluted with pure water to a mass content of single-walled carbon nanotubes of 0.07%, after stirring evenly, add Epoxy resin, the softening point of epoxy resin is 140°C, the carbon residue rate is 47%, the mass is 700g, start ultrasonic dispersion, the ultrasonic frequency is 60KHz, the ultrasonic time is 4h, stir slowly, and dry to obtain the silicon carbon negative electrode material precursor Body 1;

[0046] (2) Add the negative electrode material precursor 1 in the step (1) to the inner tan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com