Patents

Literature

46results about How to "Good fast charge and discharge capability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

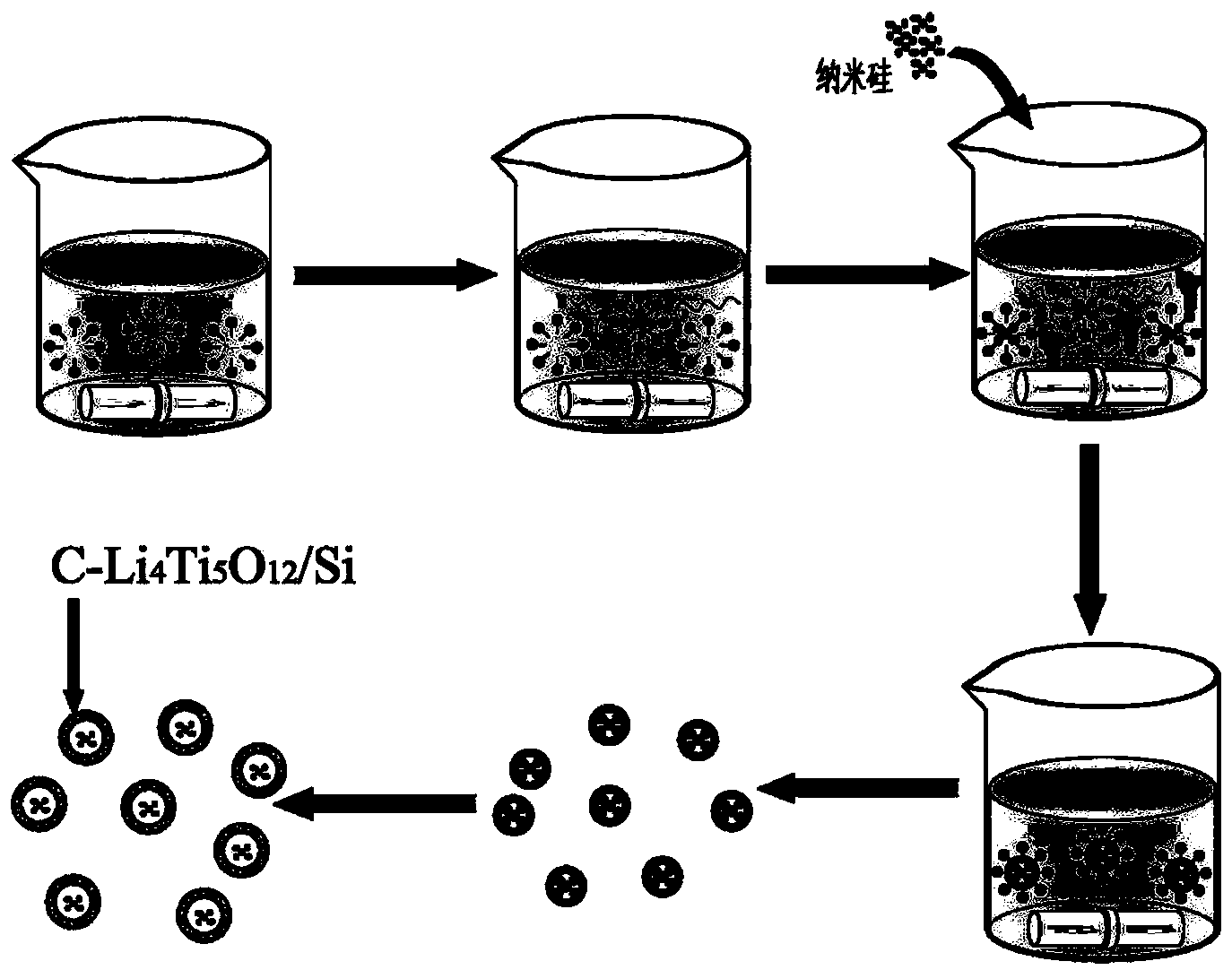

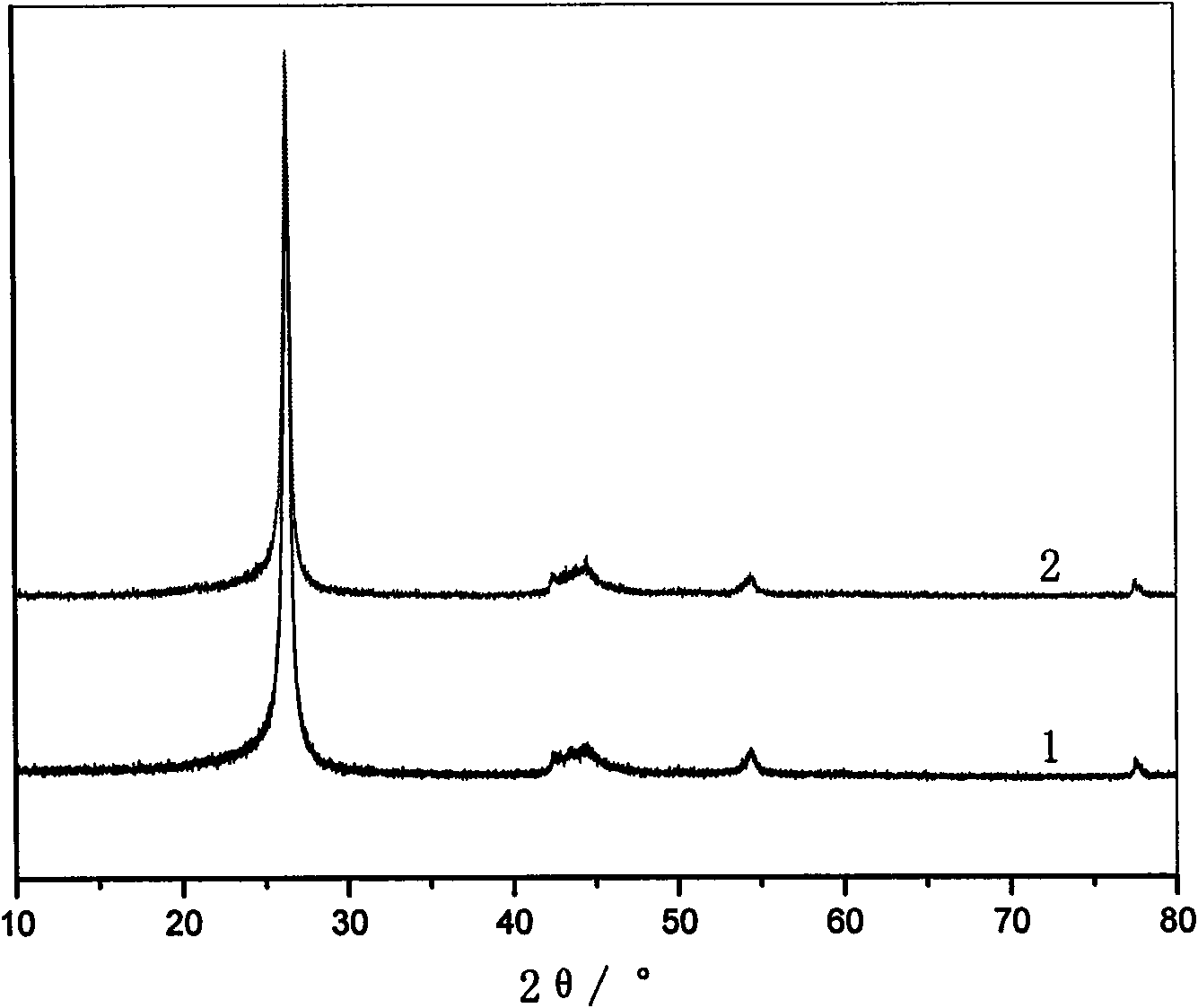

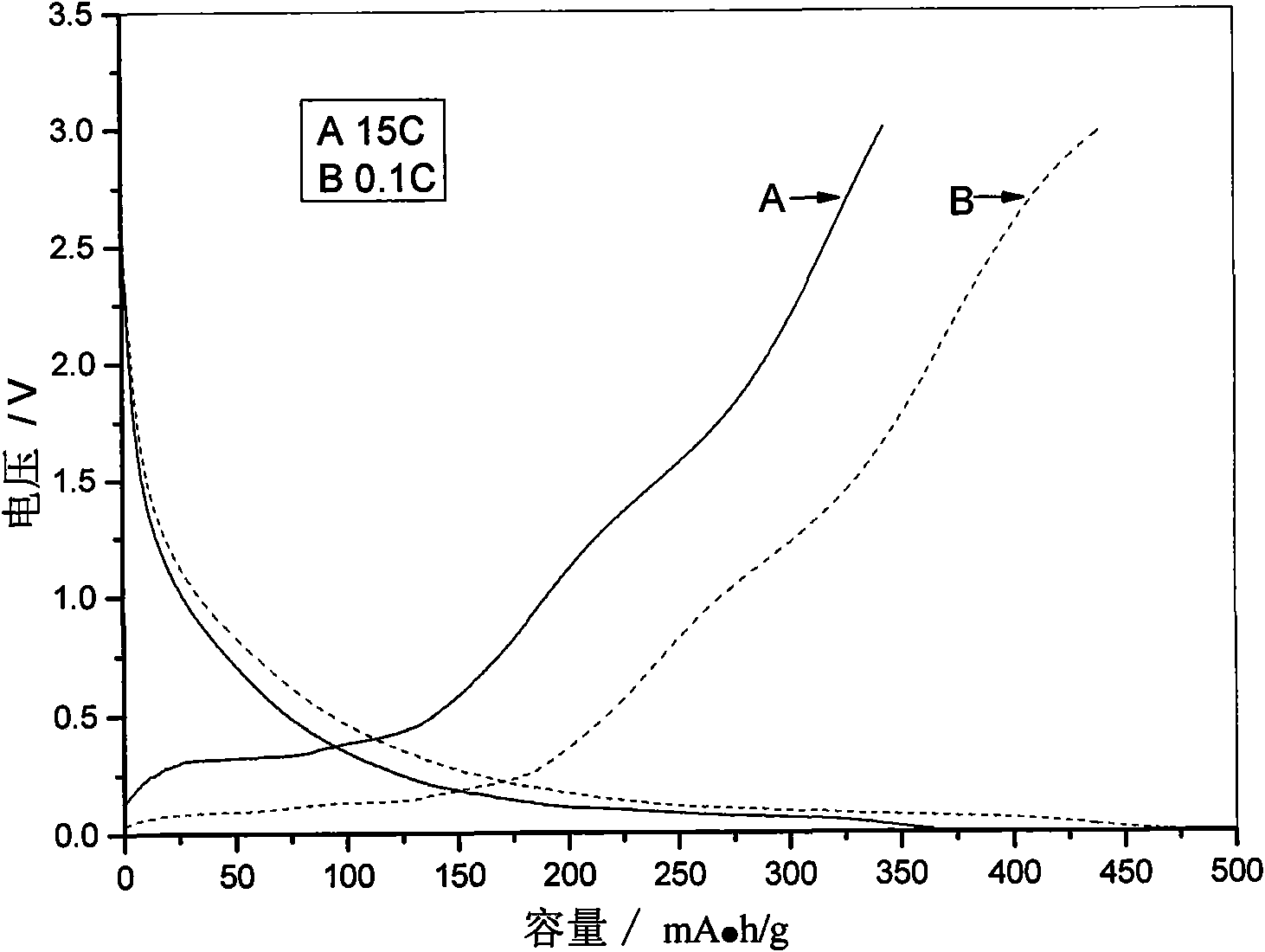

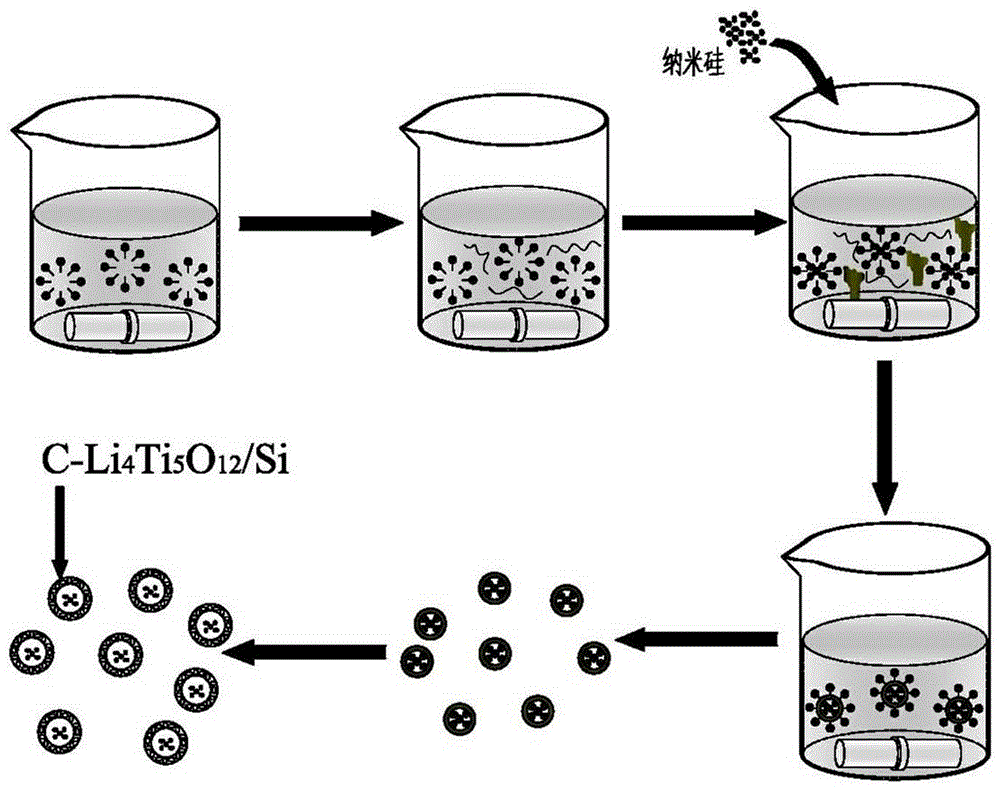

Preparation method of carbon-lithium titanate double-layer coated silicon negative electrode material

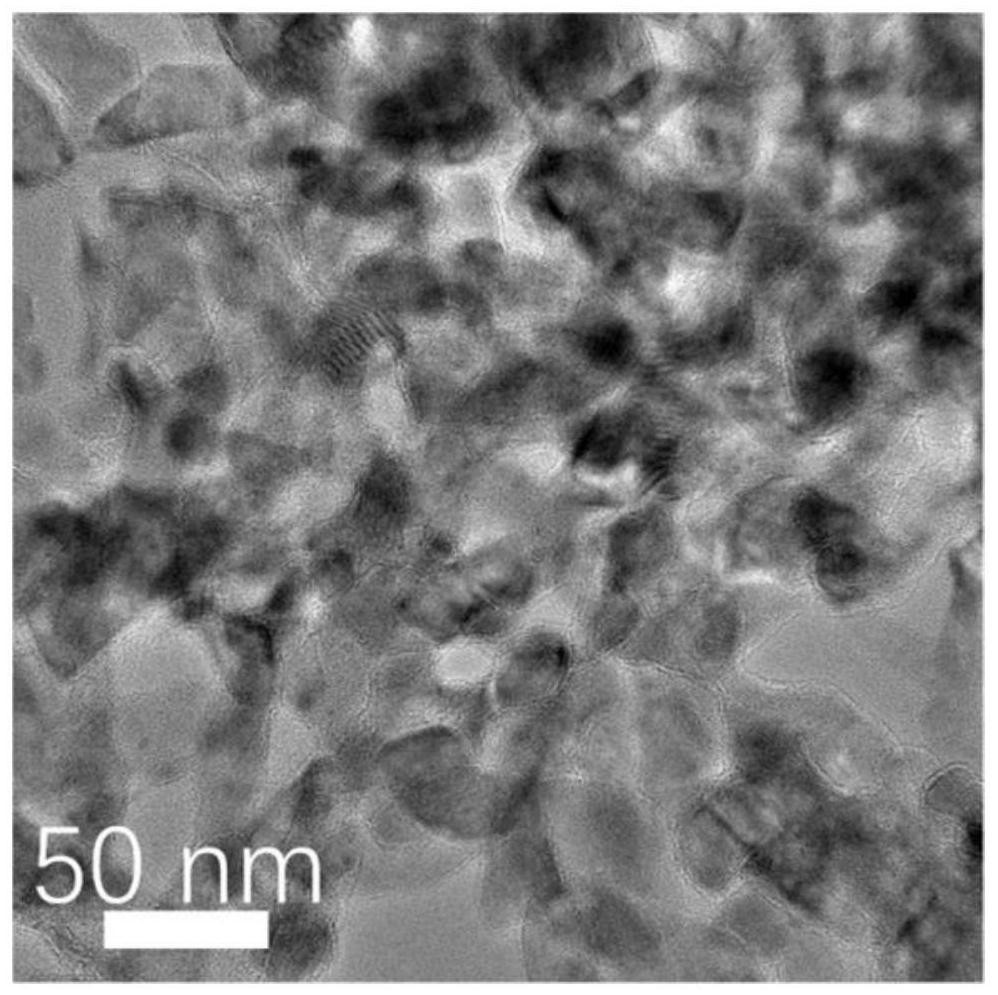

InactiveCN103682268AWell mixedUniform thicknessCell electrodesSecondary cellsNano siliconLithium compound

The invention belongs to the secondary lithium ion battery key material technical field, and provides a method for preparing a carbon-lithium titanate double-layer coated silicon negative electrode material. With chelating agents as carbon sources, a soluble Ti compound as a titanium source, a nano silicon source and various lithium compounds as lithium sources, the carbon-lithium titanate double-layer coated silicon negative electrode material is synthesized by a double-chelating-agent sol-gel method. Through combination of advantages of lithium titanate and the silicon material, a prepared lithium ion battery has high specific capacity, excellent cycling stability and quite high consistency, allows the high specific capacity and the high stability to be organically gathered together, and has wide application prospects.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

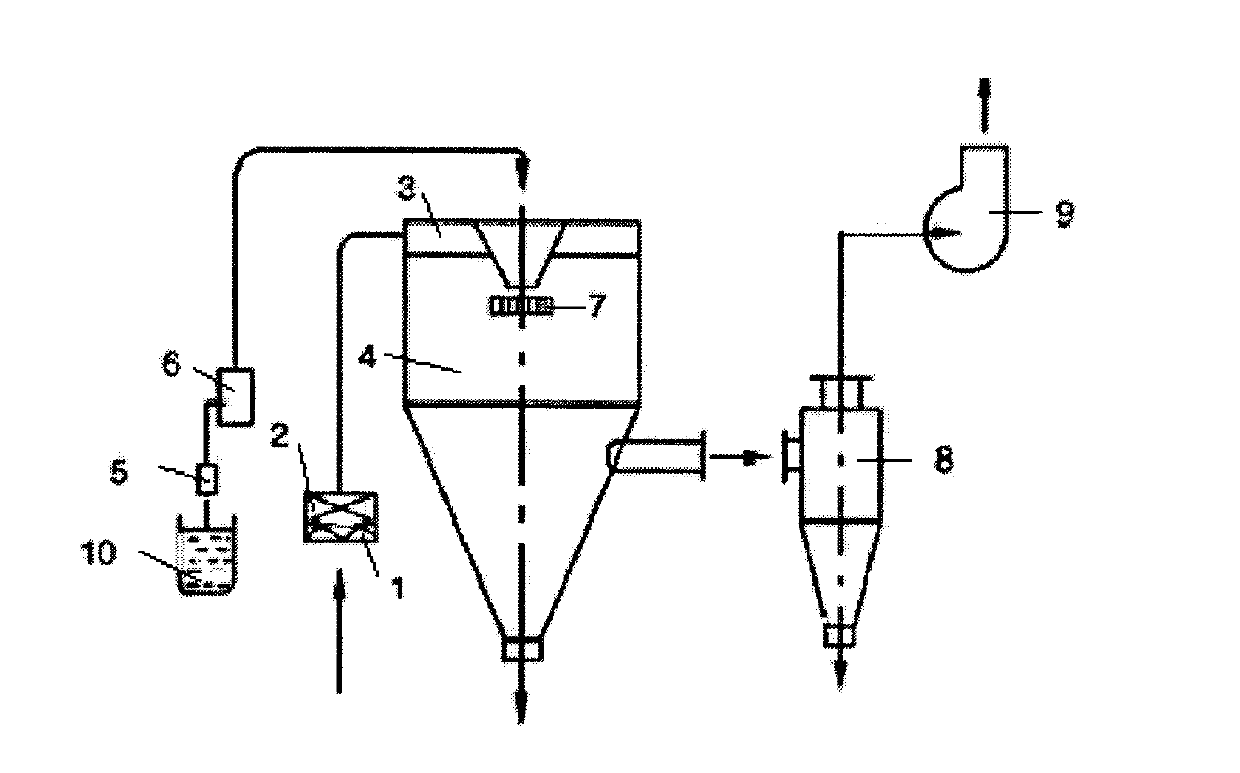

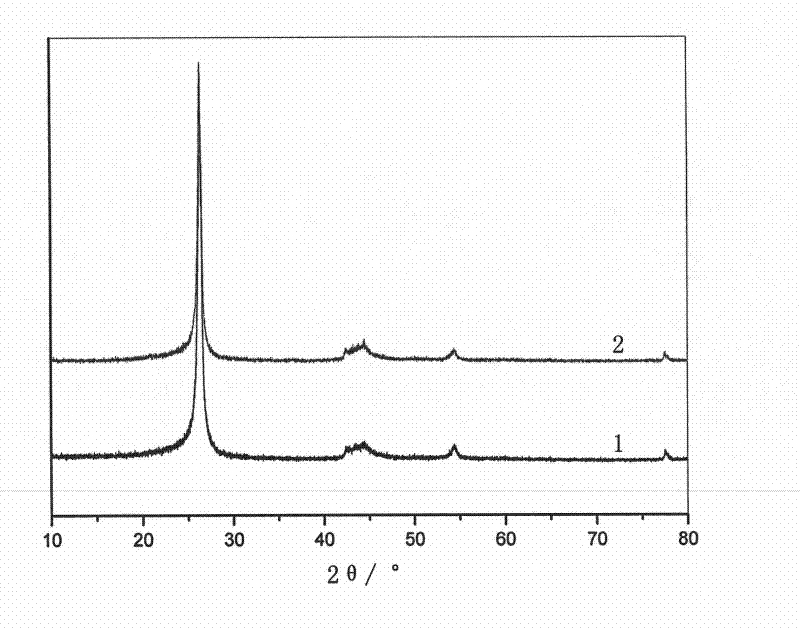

Method for the preparation of high rate lithium ion capacitor battery cathode material by pyrolyzing asphalt at low temperature to cover graphite

InactiveCN101604748AImprove charge and discharge efficiencyImprove the degree of graphitizationElectrode manufacturing processesCapacitanceAlcohol

The invention relates to a method for the preparation of high rate lithium ion capacitor battery cathode material by pyrolyzing asphalt at low temperature to cover graphite, belonging to the technical field of the preparation of energy storage material. The invention comprises the steps that: first, mixed solution containing graphitizing catalyst, water and alcohol is formulated, then graphite, asphalt powder and conductive agent are added therein for being mixed for several hours, the resultant mixture is dried in an atmosphere of the air, the asphalt is then pyrolyzed in an atmosphere of Ar or N2, and in the end, salpeter solution is used to remove the graphitizing catalyst by means of dissolution, and the high rate lithium ion capacitor battery cathode material with pyrolyzed asphalt covering the graphite is obtained by sufficient washing and drying. The cathode material obtained according to the method has the characteristics of high capacity and good high rate performance, is simple in process flow and includes tremendous application value.

Owner:CENT SOUTH UNIV

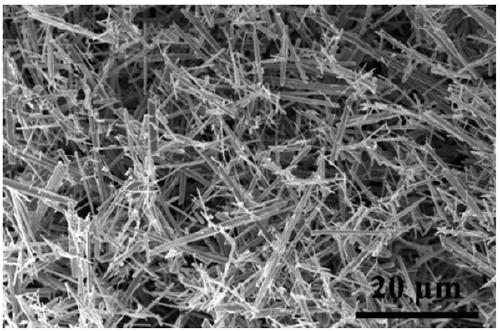

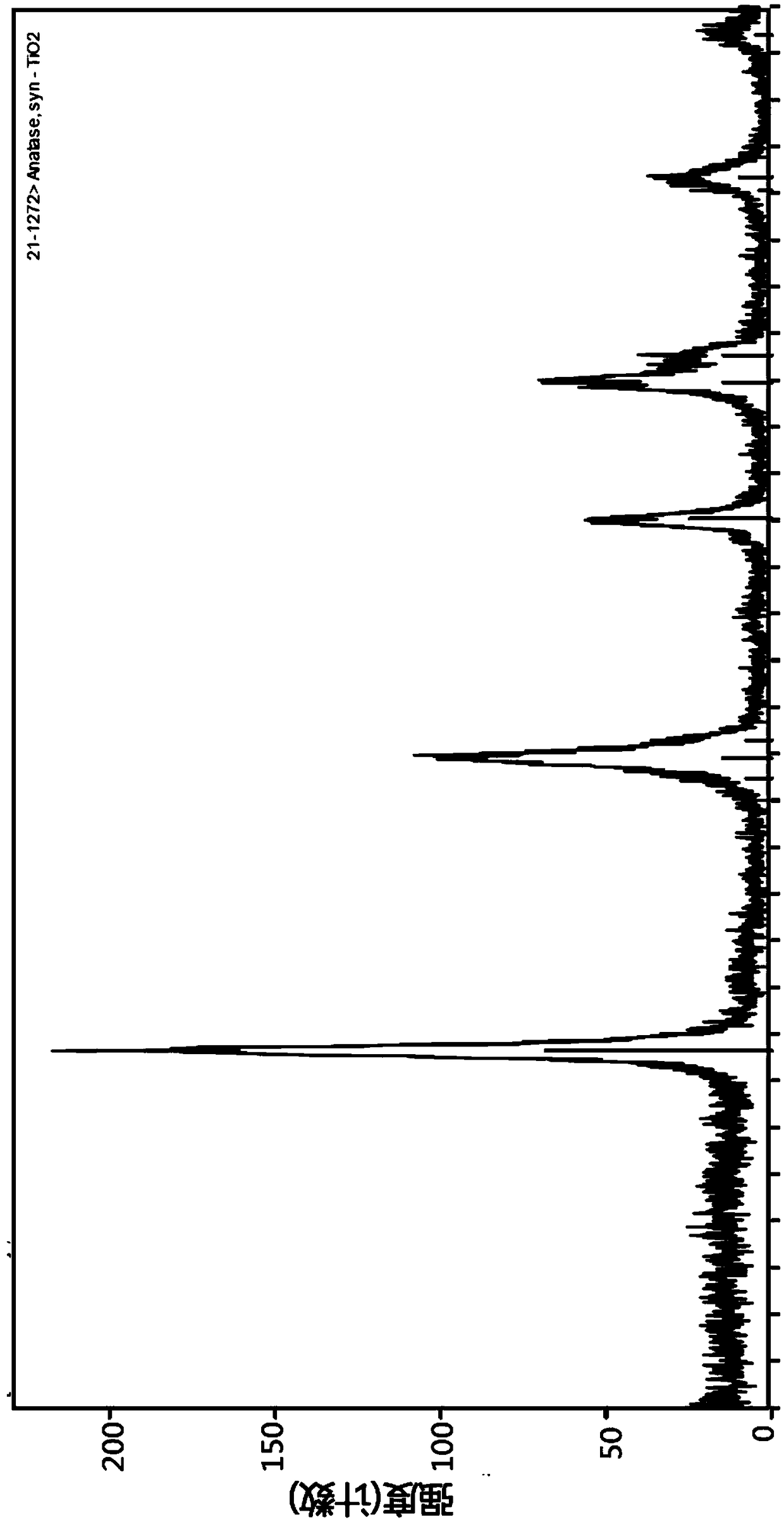

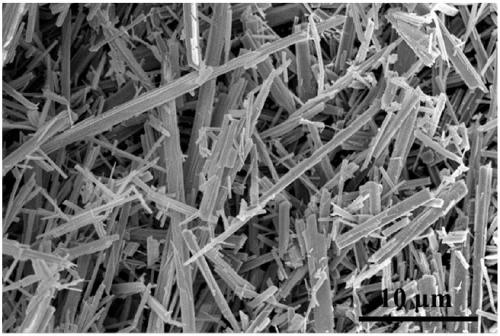

Linear porous titanium dioxide material and preparation method and application thereof

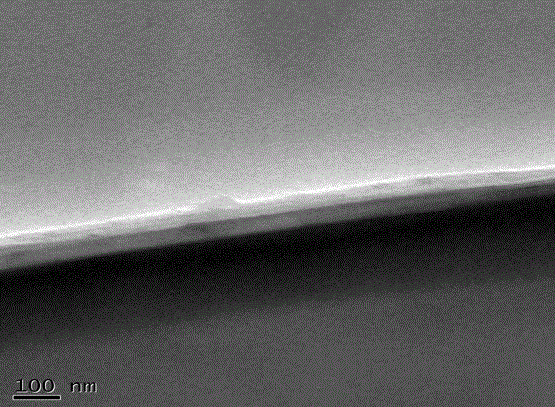

ActiveCN109319832ALarge specific surface areaGood application effectMaterial nanotechnologyAlkali titanatesElectrolytic agentNanowire

The invention provides a linear porous titanium dioxide material and a preparation method and application thereof. The linear porous titanium dioxide material is of an anatase-phase structure and a monocrystalline structure, and structurally consists of a plurality of particles; each particle has the fixed growth direction. The invention also provides the preparation method and application of thelinear porous titanium dioxide material. The titanium dioxide porous nanometer line has the advantages that the long axis of the structure is suitable for the effective transfer of electrons, so as tofacilitate the hydrogenation by photolysis of water, or degradation of organic pollutants by photocatalysis; the porous structure is suitable for the quick embedding-in and embedding-out process of lithium ions, sodium ions or potassium ions; the large specific surface area is suitable for the contact area between an electrolyte and an electrode, so that the current density is reduced, and the better battery quick charge and discharge property is realized.

Owner:PETROCHINA CO LTD

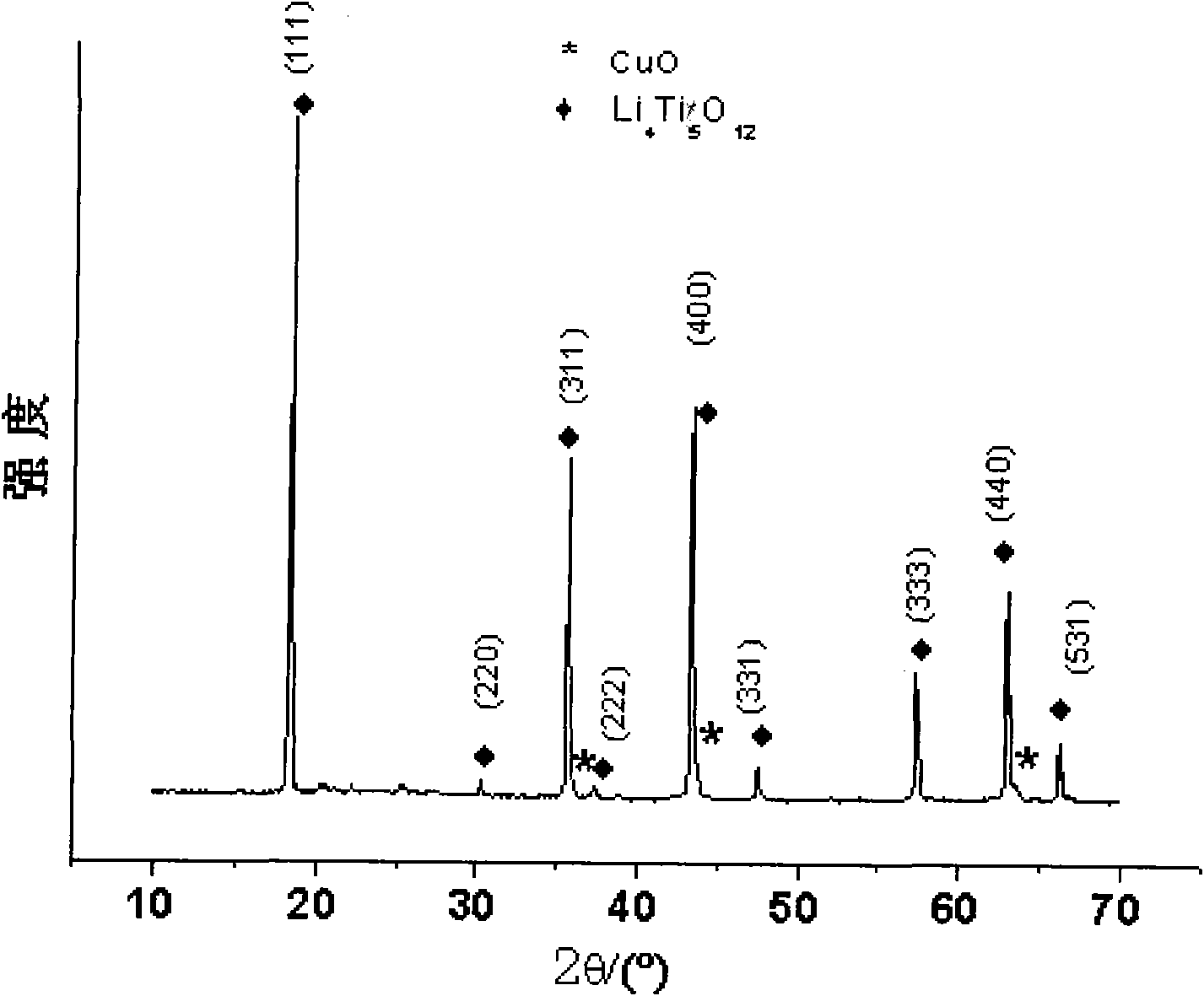

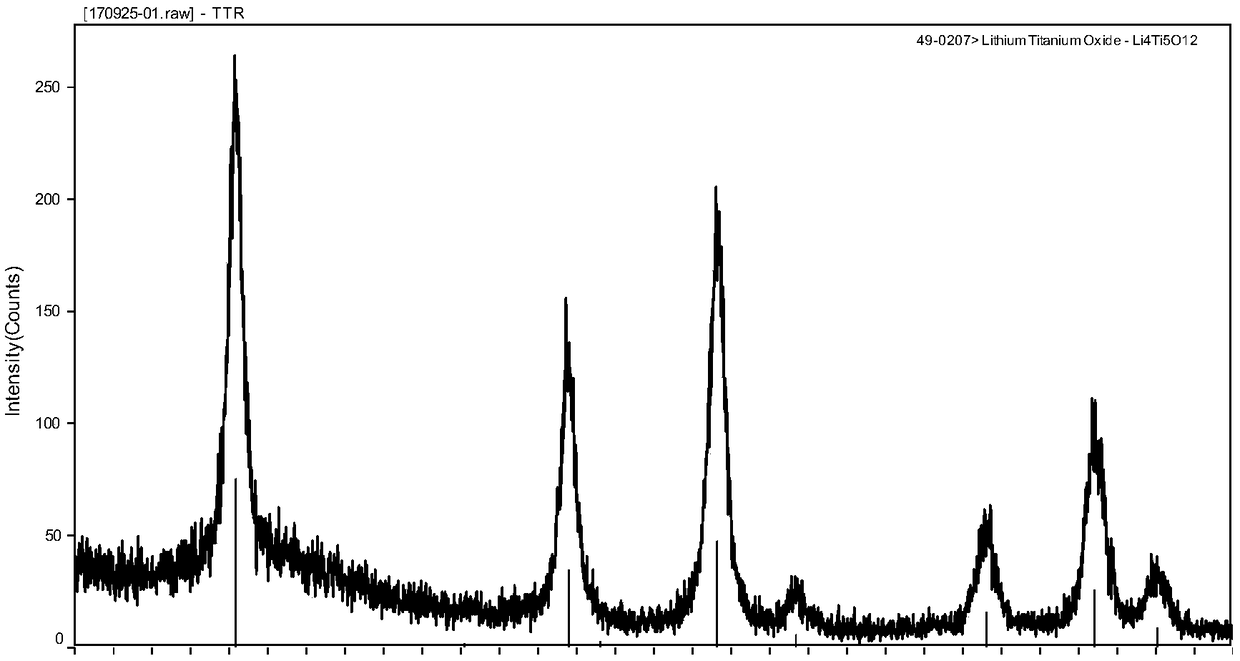

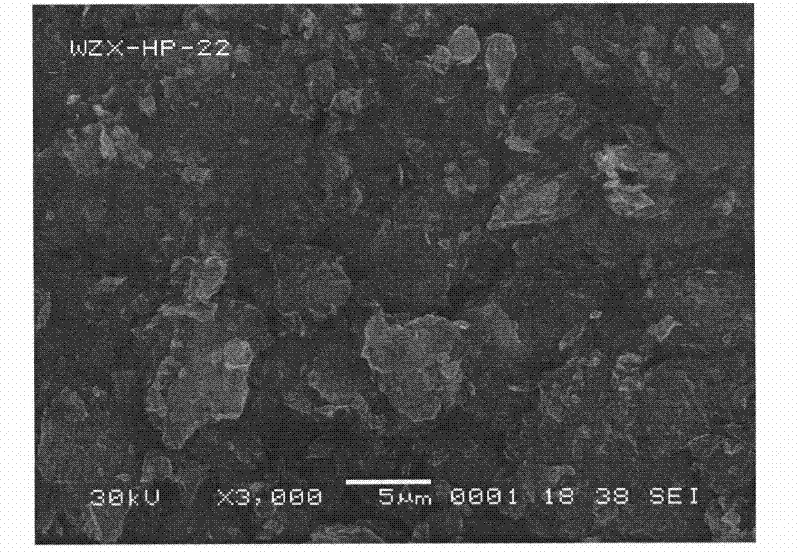

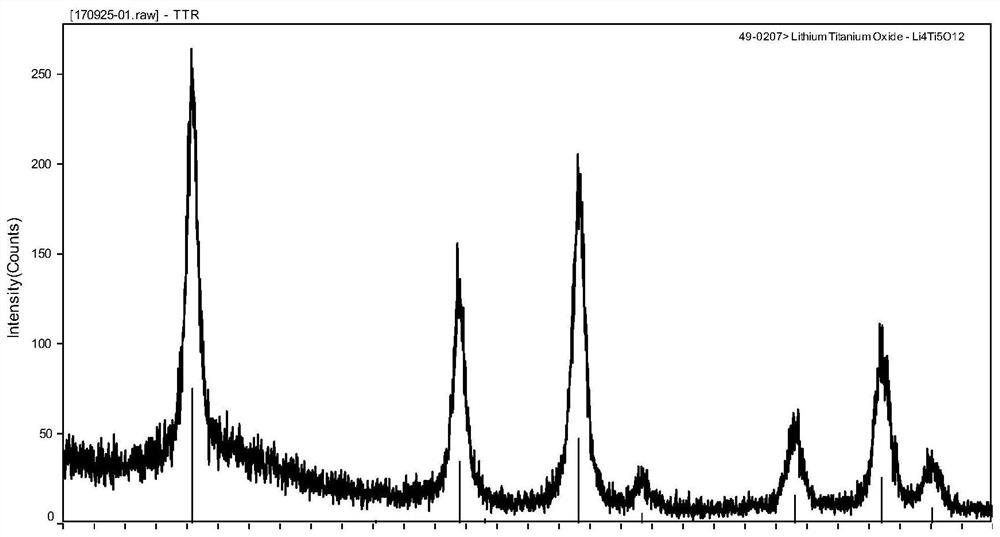

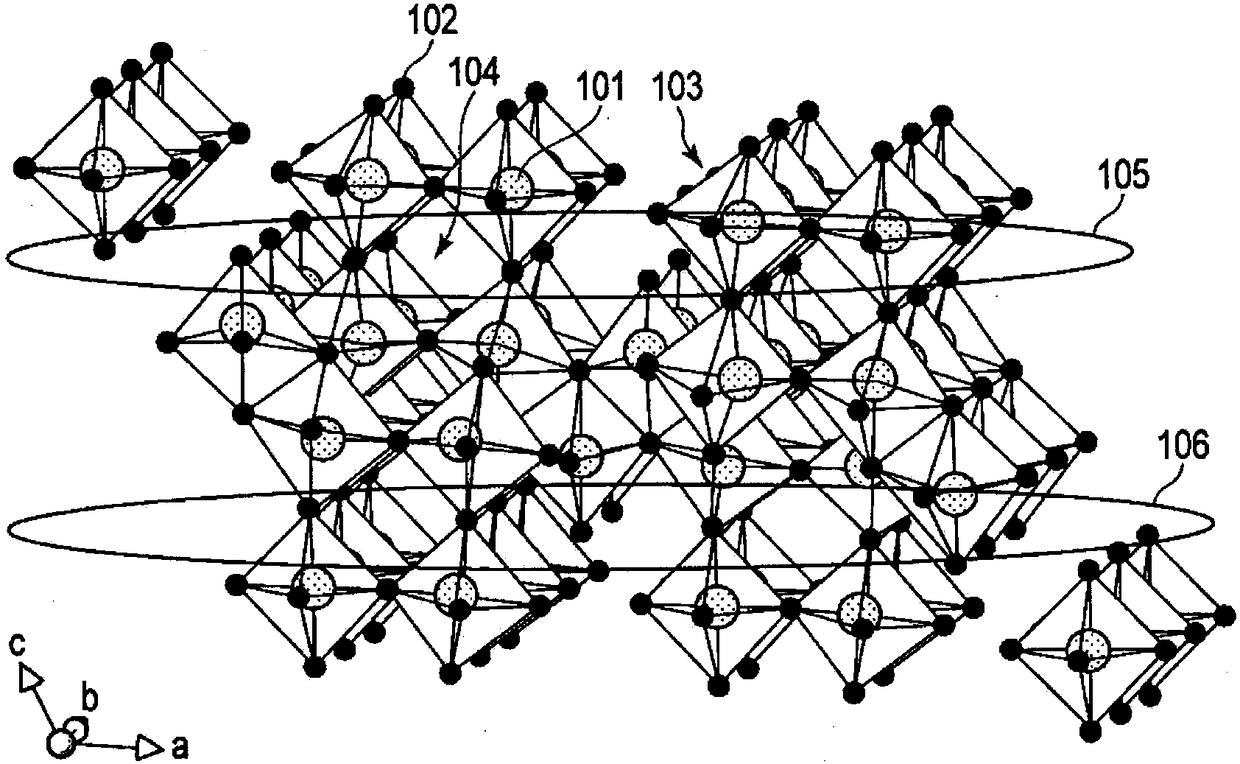

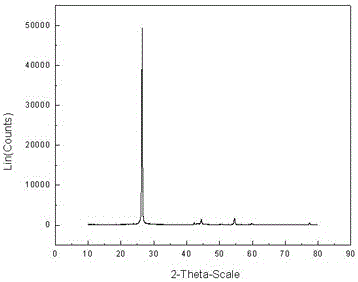

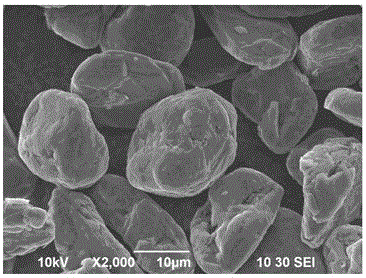

Preparation method of lithium titanate composite negative electrode materials used by lithium ion batteries

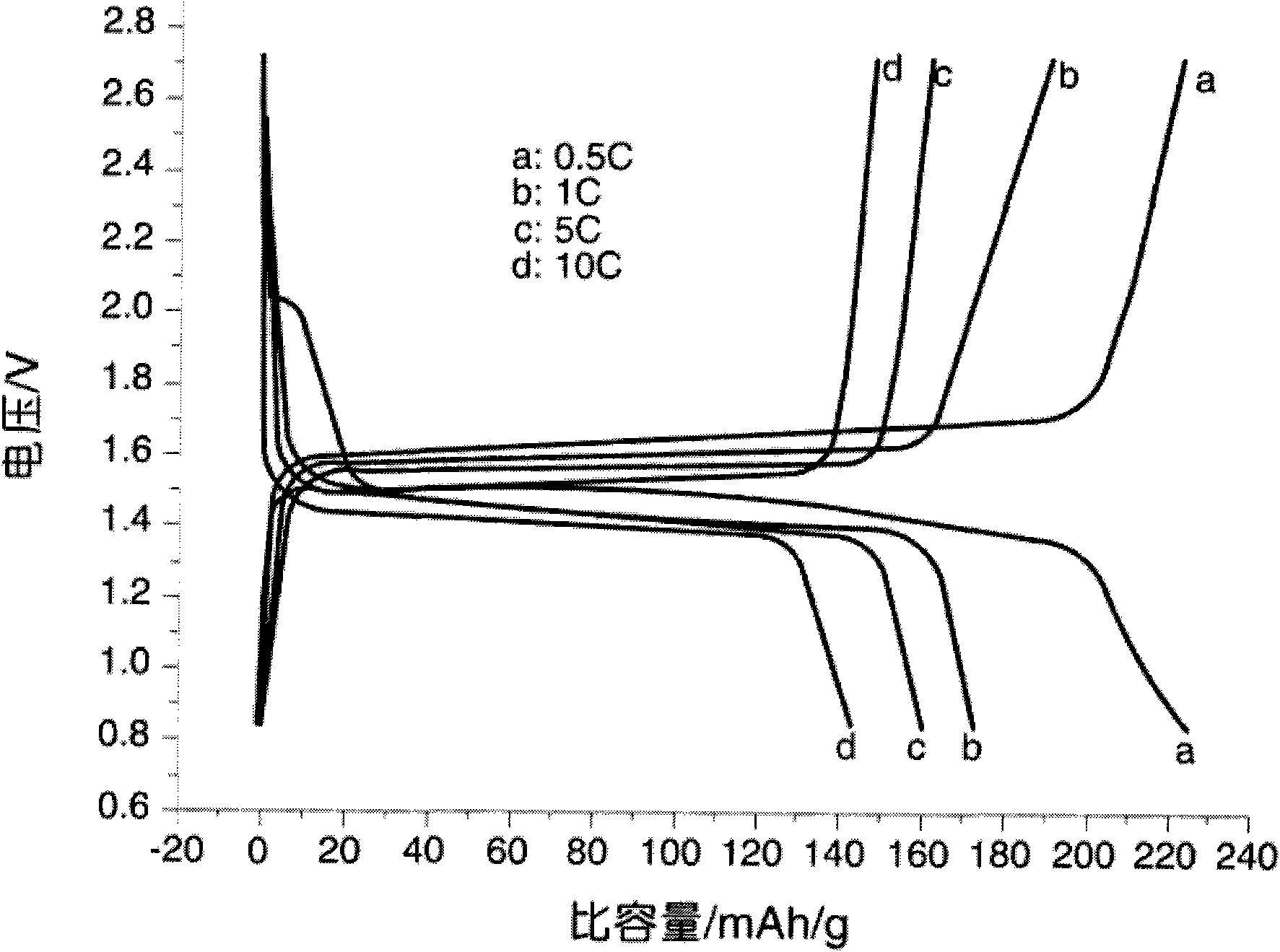

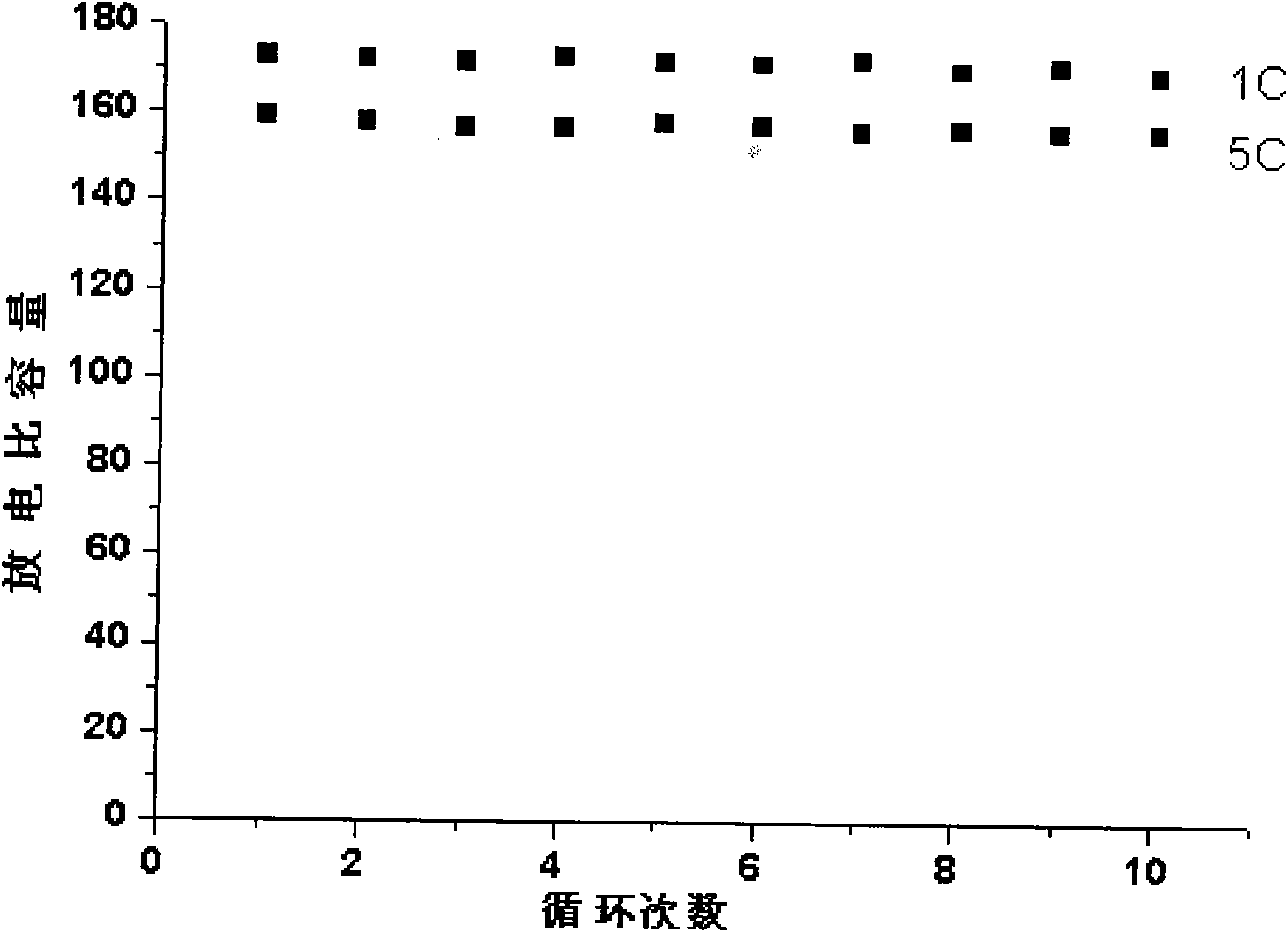

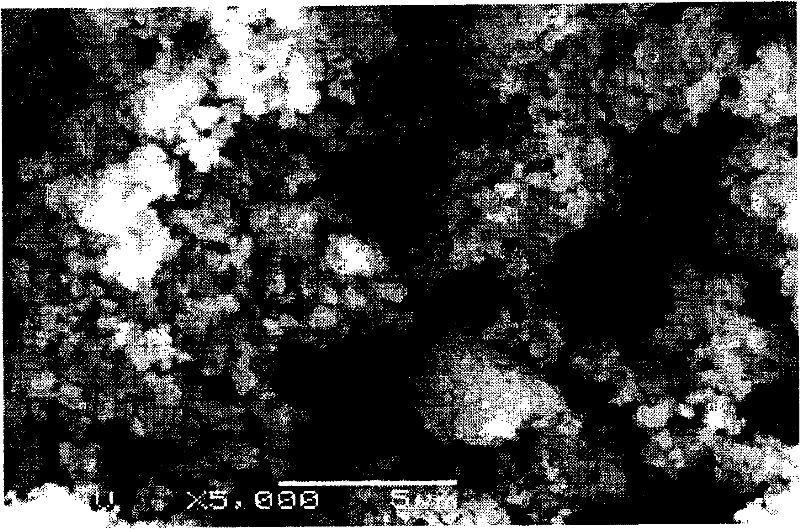

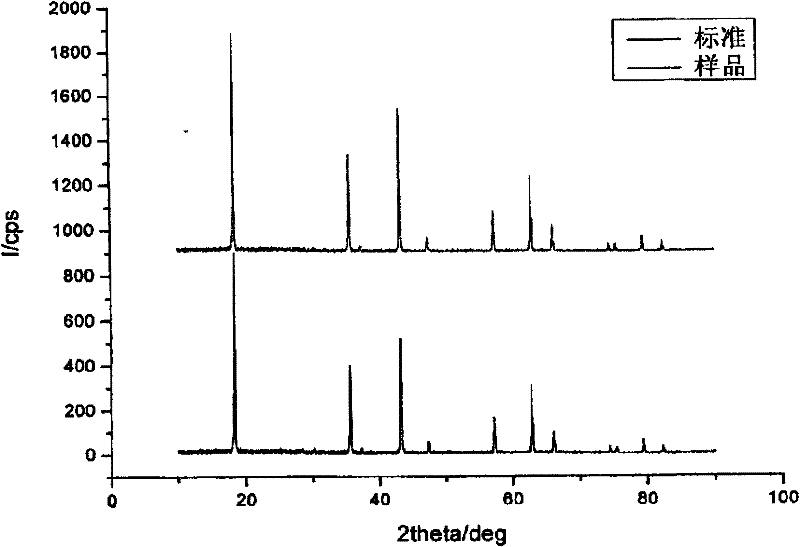

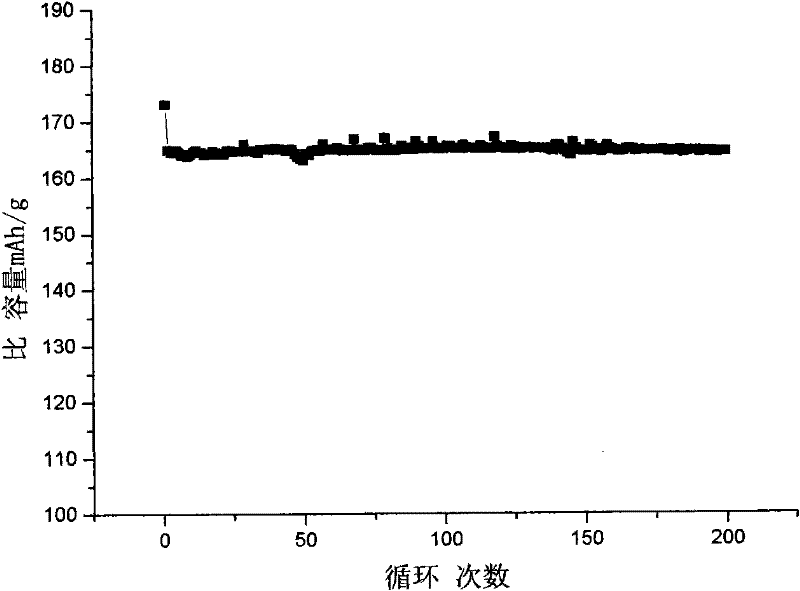

The invention discloses a preparation method of lithium titanate composite negative electrode materials used by lithium ion batteries, which is characterized in that the method comprises the following steps: proportionally mixing Li2CO3 powder and TiO2 powder; then, adding organic solvents into the mixture to be simultaneously prepared into paste materials; drying the paste materials after ball milling; raising the temperature; preserving the temperature; carrying out ball milling after cooling to obtain Li4Ti5O12; adding Li4Ti5O12 into metal compounds to simultaneously carry out ball milling; and then, completing the preparation through drying, temperature rising, temperature preservation, cooling and fine grinding. The lithium titanate of the composite negative electrode materials of the lithium ion batteries prepared by the method of the invention can adopt a general formula of Li4Ti5O12 / MOx, wherein x is 1 when M is Cu, and x is 0 when M is Ag. The lithium titanate can be used as the negative electrode materials of the lithium ion batteries, and has the advantages of good fast charging and discharging capability, high safety performance, no pollution and excellent large-magnification charging and discharging performance. The invention is applicable to industrial production, and can be applied to the fields of electric automobiles, energy storing equipment and electric tools.

Owner:HEFEI UNIV OF TECH

Titanium acid lithium battery cathode material containing rare metal elements

InactiveCN102054963AImprove fast charge and discharge performanceHigh electrochemical capacityCell electrodesIndustrial scaleRare-earth element

The invention relates to titanium acid lithium battery cathode material containing rare metal elements, which comprises a synthesized lithium titanate material. A or a plurality of rare metal elements are contained in the lithium titanate material; the rare metal elements adopt Zr, Al, La, Ce, Pr, Nd, Sm and Dy or Ho; the contents of the rare metal elements are 0.01-3 wt percent by oxidate; the lithium and titanium molar ratio in the lithium titanate material is 0.7-1.2; and the titanium acid lithium battery cathode material is produced by adopting the processes of material mixing, ball milling and sieving, high-temperature treatment, secondary ball milling, high-temperature heat preservation and the like. The titanium acid lithium battery cathode material containing the rare metal elements is doped with the rare metal elements, improves the quick charging and discharging properties, improves the electrochemical capacity and has excellent cycle performance, good repeatability and high consistency; and furthermore, the titanium acid lithium battery cathode material has the advantages of low raw material cost, short synthesis time, low temperature, low requirements for equipment and simple manufacturing process and is suitable for industrial scale production.

Owner:RISESUN MENGGULI NEW ENERGY SCIENCE & TECHNOLOGY CO LTD

Composite conductive paste, preparation method and use thereof

InactiveCN109830685AOvercome the Difficulty of ScatteringGood dispersionCell electrodesSecondary cellsConductive pasteCarbon nanotube

The invention relates to a composite conductive paste, a preparation method and use thereof. The composite conductive paste of the invention comprises a composite material composed of a carbon nanotube and grapheme. The grapheme is less-layer graphene (10-20 layers), and the carbon nanotube is a multi-walled carbon nanotube. The composite conductive paste solves the problem that the two nanomaterials including the carbon nanotube and the graphene are difficult to disperse. The prepared composite conductive paste has good electrical conductivity and a resistivity of 32[omega].cm to 35[omega].cm. An electrode pole piece prepared from the composite conductive paste of the invention has high electrical conductivity, can improve the electrical conductivity and the electrochemical performance ofthe whole battery. An assembled battery has good fast charge and discharge performance, good reversibility and stability.

Owner:哈尔滨万鑫石墨谷科技有限公司

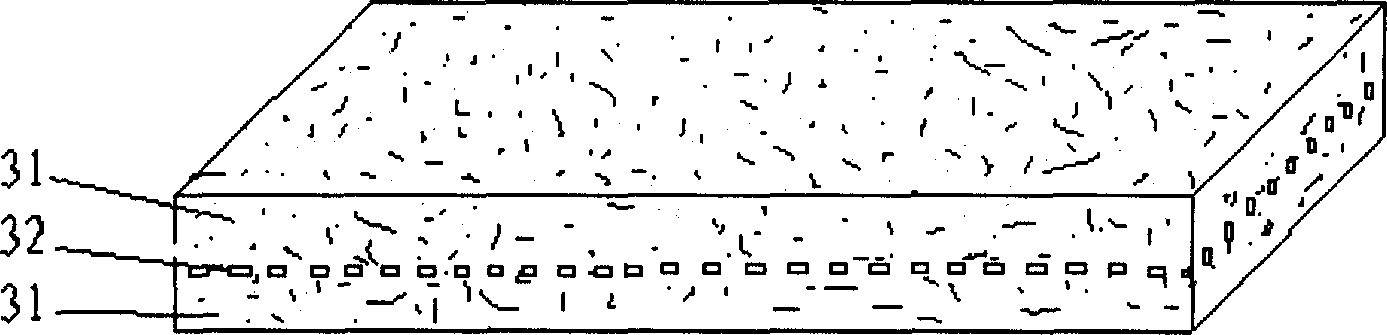

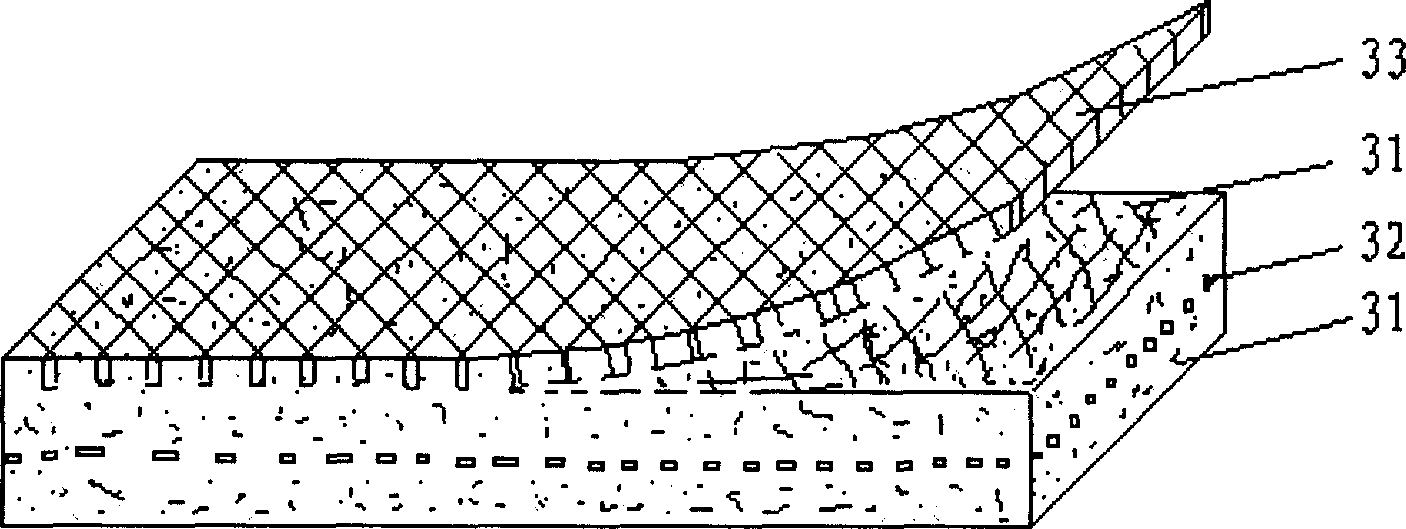

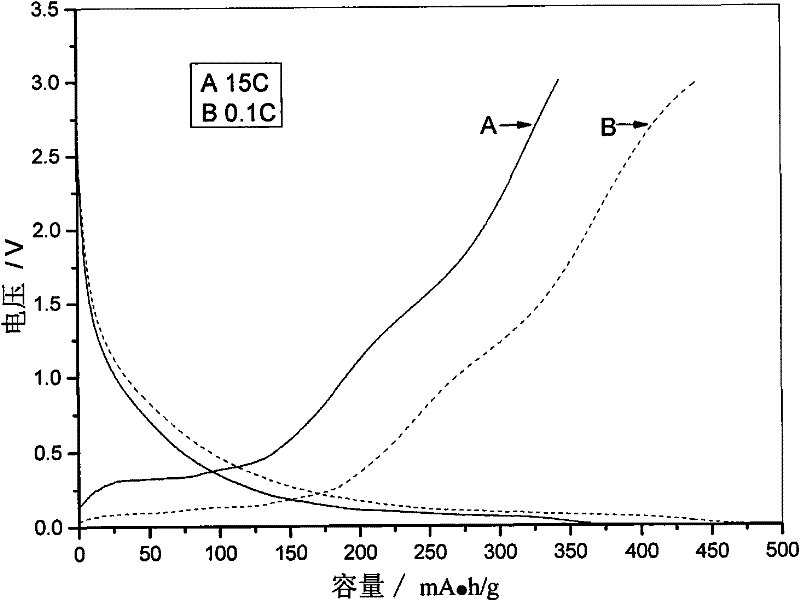

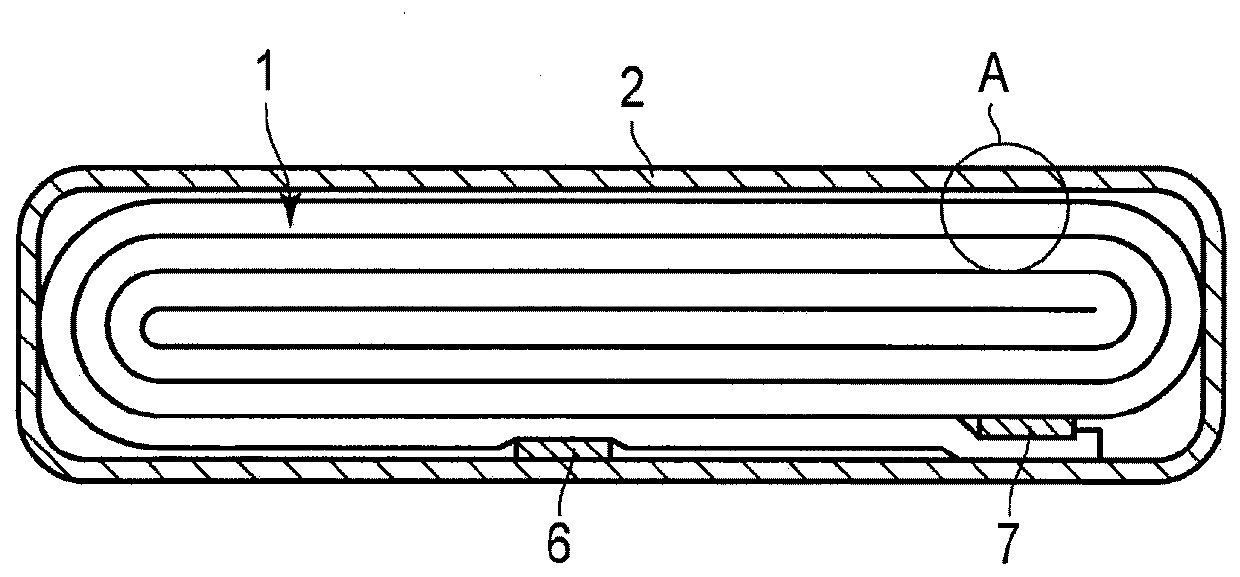

Accumulator and its preparing method

InactiveCN1722506ALower internal resistanceImprove discharge capacityElectrode manufacturing processesFinal product manufactureEngineeringVoltage

This invention relates to an accumulator, comprising the following steps: joining the positive plate, baffle plate, negative plate and electrolytic solution in the cell housing, wherein, the positive and negative plates is formed by coating active material on both sides of the metallic base, and one lateral side of at least one of the positive and negative plates is located with metallic net embedded in the lateral side of the plate. The invention has the advantages of simple structure of accumulator plate, lower essential resistance, higher discharge capacity and simple preparing method.

Owner:SHANGHAI BYD

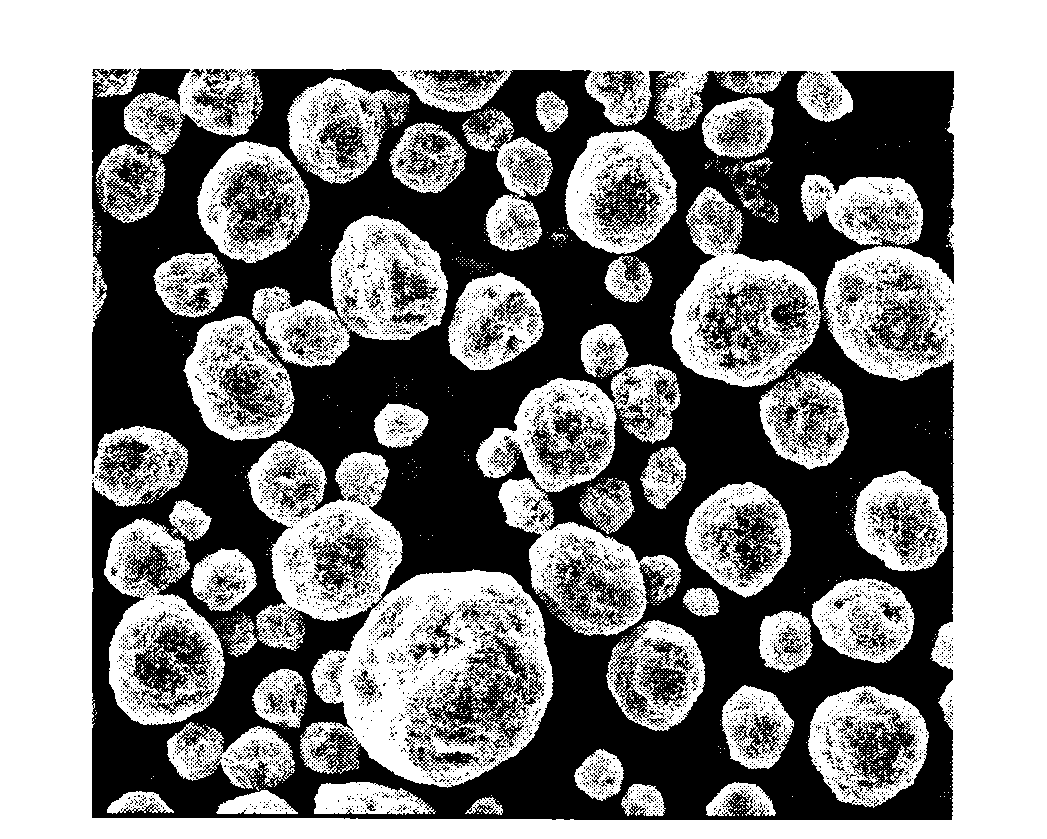

TiO2-coated graphite composite particle for lithium ion battery, and preparation method and application thereof

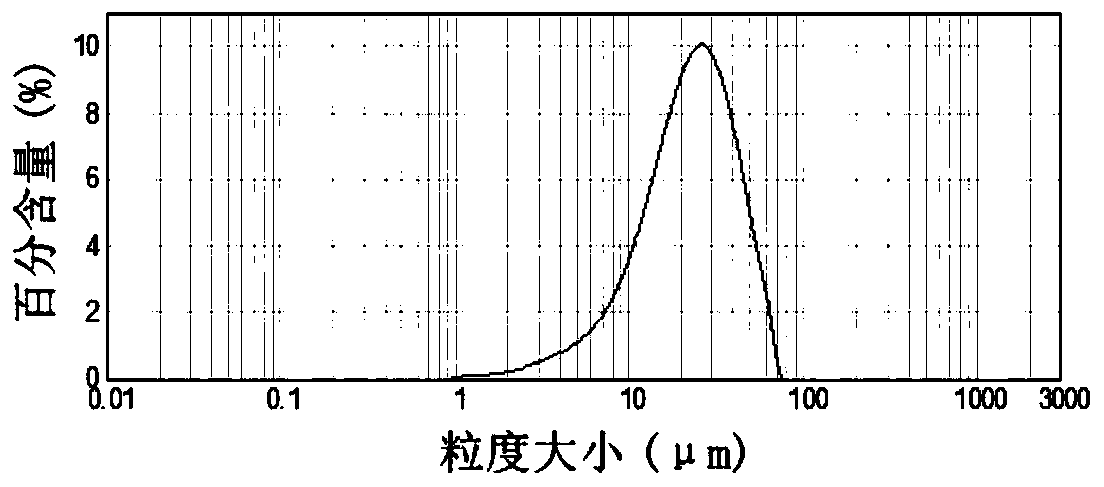

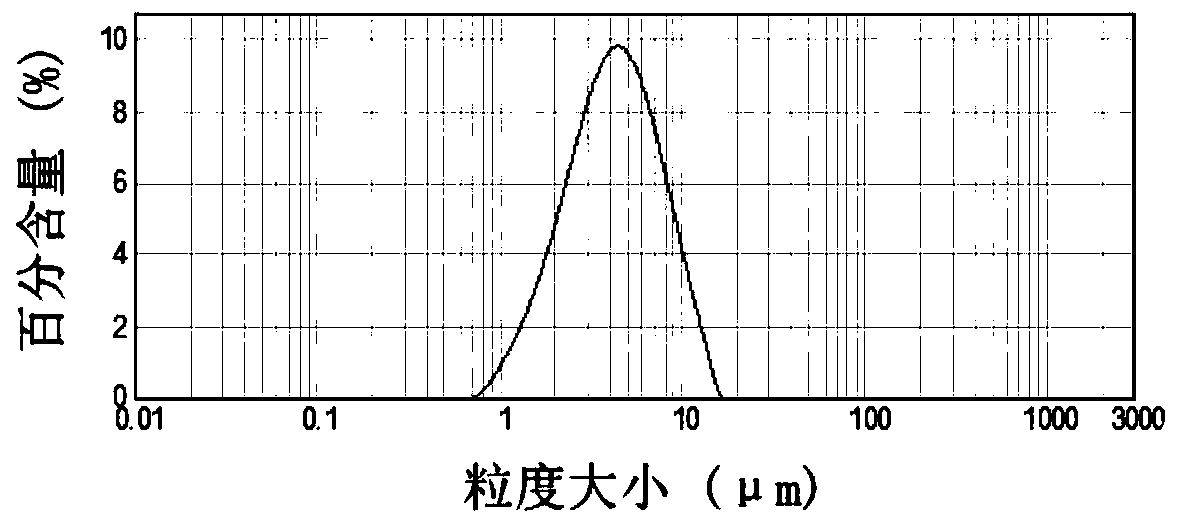

The invention provides a TiO2-coated graphite composite particle for a lithium ion battery and a preparation method and application thereof. The method comprises the following steps: (1) mixing spherical graphite with TiO2 sol with stirring so as to obtain mixed slurry; and (2) drying and granulating the mixed slurry by using spray granulation equipment under the protection of inert gas, taking a cyclone material with a median particle diameter of 5 to 15 mu m and subjecting the cyclone material to heat treatment at a temperature of 400 to 800 DEG C under the protection of inert gas; wherein in the step (1), the median particle diameter of the spherical graphite is 5 to 14 mu m, the concentration of TiO2 in the TiO2 sol is 0.2 to 2.0 mol / L, and the spray granulation equipment has an air inlet temperature of 250 to 350 DEG C and an air outlet temperature of 70 to 100 DEG C. According to the invention, high-rate charge and discharge performance of graphite is improved, the phenomenon of precipitation of lithium from the surface of graphite in the process of heavy current charge and discharge is avoided, security of a material is enhanced, an obtained composite material has capacity substantially higher than the capacity of a pure TiO2 material, and the preparation method is simple to operate and applicable to industrial production.

Owner:SHANGHAI SHANSHAN TECH CO LTD

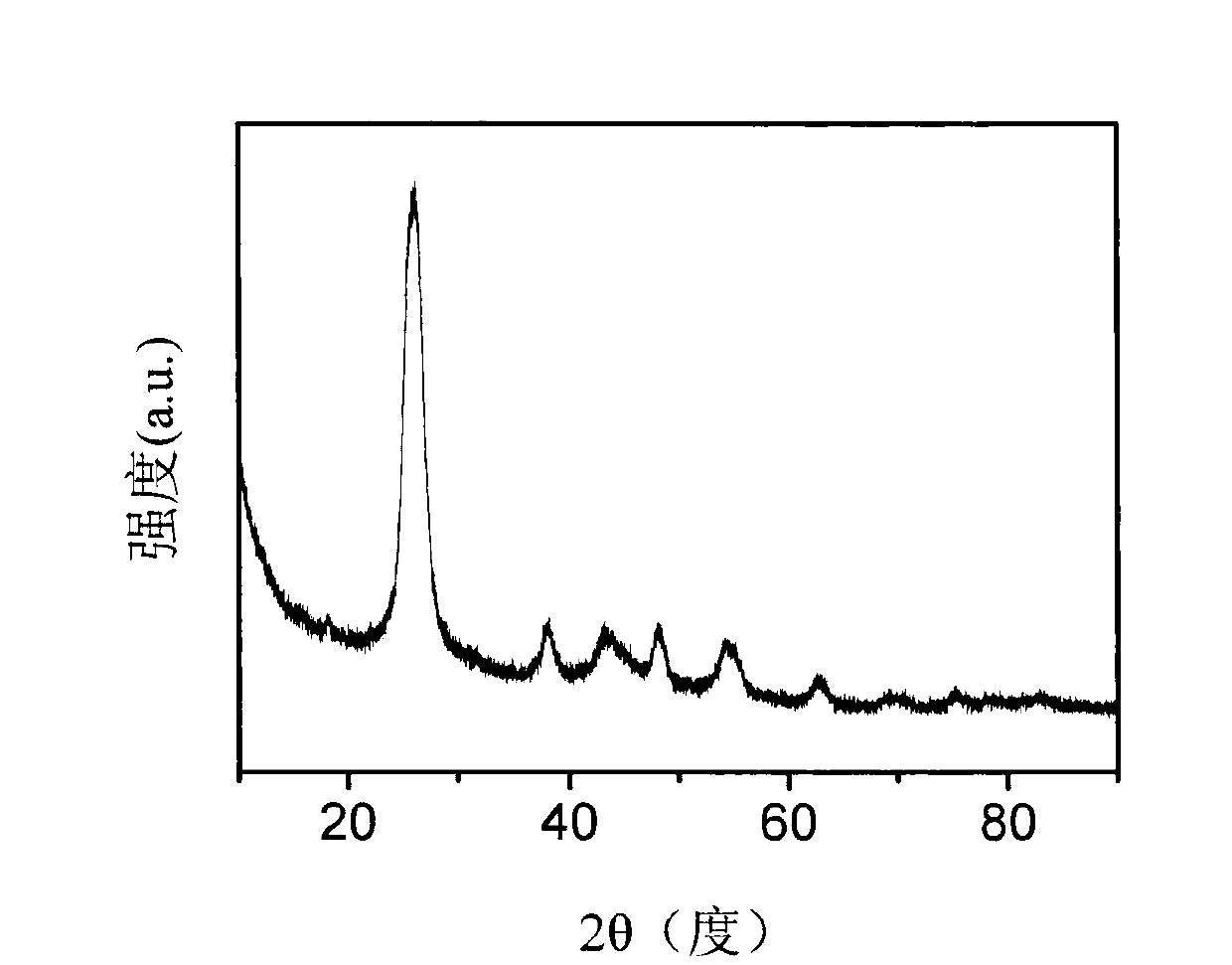

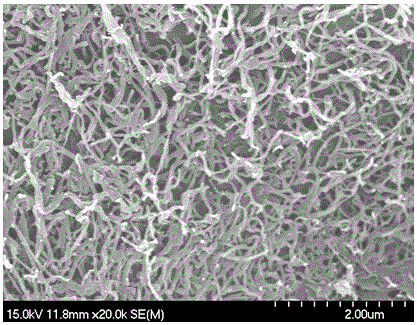

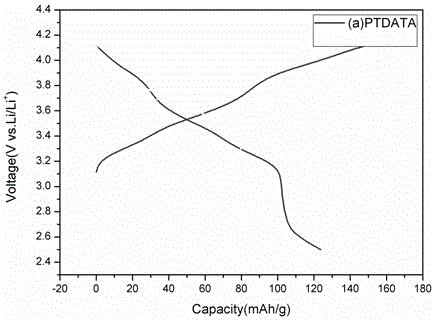

Micro-mesoporous polytriphenylamine derivative applied to lithium battery, as well as preparation method thereof

InactiveCN106207182AExcellent charge and discharge performanceHigh charge-discharge specific capacityCell electrodesSecondary cellsChemistryLithium electrode

The invention provides a micro-mesoporous polytriphenylamine derivative applied to a lithium battery, as well as a preparation method thereof, relates to a lithium ion battery material and a preparation method thereof, and discloses a micro-mesoporous structured polytriphenylamine derivative with high free radical density, an application thereof and a lithium battery prepared from the polytriphenylamine derivative. The micro-mesoporous structured polytriphenylamine derivative is prepared by taking 4,4',4'-tris(N,N-diphenylamino)triphenylamine as a monomer by virtue of a chemical oxidative polymerization method. Such a polytriphenylamine derivative material is of a micro-mesoporous structure and fiber morphology, is used as a lithium ion battery cathode material, and has high charge and discharge performance, cyclic stability and rate performance.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

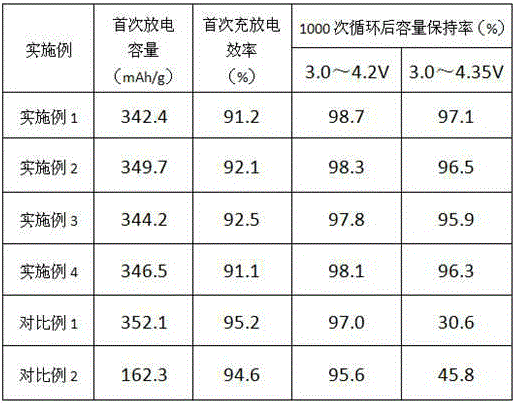

Manufacturing method for high-voltage lithium ion anode material

InactiveCN104916834AIncrease energy densityGood fast charge and discharge capabilityCell electrodesSecondary cellsGraphiteOptoelectronics

The invention provides a manufacturing method for a high-voltage lithium ion anode material. A lithium battery manufactured with the preparation method can be quickly recharged and discharged, and the recharging cut-off voltage is increased to 4.35V, so that the energy density of the lithium battery is greatly increased. The anode material manufactured with the manufacturing method takes lithium titanate as a core, the surface of lithium titanate is uniformly coated with a layer of graphite, and the surfaces of lithium titanate particles coated with the graphite are further coated with a layer of conductive agent, as a result, a lithium titanate-graphite-conductive agent three-layer composite structure is formed. The manufactured battery has very good performance of quick recharging and discharging and is greatly improved in high and low temperature performance and safety.

Owner:田东

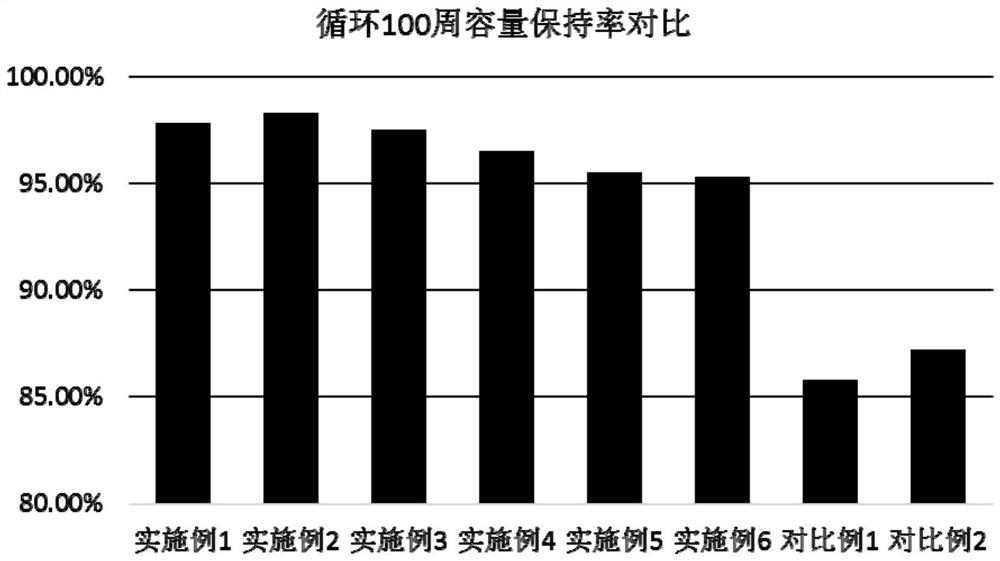

Preparation method of lithium battery high-voltage modified cathode material

InactiveCN104916825AIncrease energy densityGood fast charge and discharge capabilityCell electrodesSecondary cellsElectrical batteryGraphite particle

The invention provides a preparation method of a lithium battery high-voltage modified cathode material. A lithium battery made of the cathode material can be charged and discharged rapidly; the charging cut-off voltage is raised to 4.35V; and the energy density of the battery is greatly increased. In the cathode material prepared with the method, graphite is taken as a core, the surface of the graphite is uniformly coated with a layer of lithium titanate, and the surfaces of graphite particles coated with the lithium titanate are coated with a layer of conductive agent, thereby forming a graphite-lithium tianate-conductive agent three-layer composite structure. The obtained battery has high rapid charging-discharging performance, and the low-temperature performance is improved greatly. Meanwhile, the safety performance is improved greatly.

Owner:田东

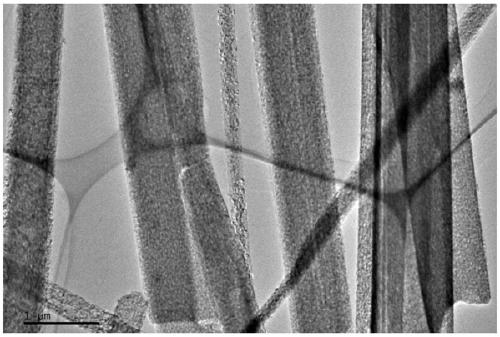

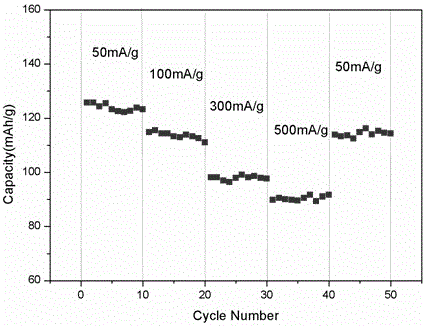

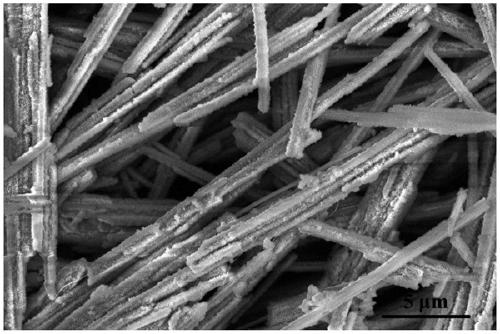

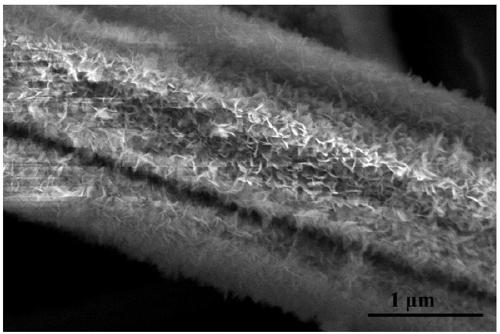

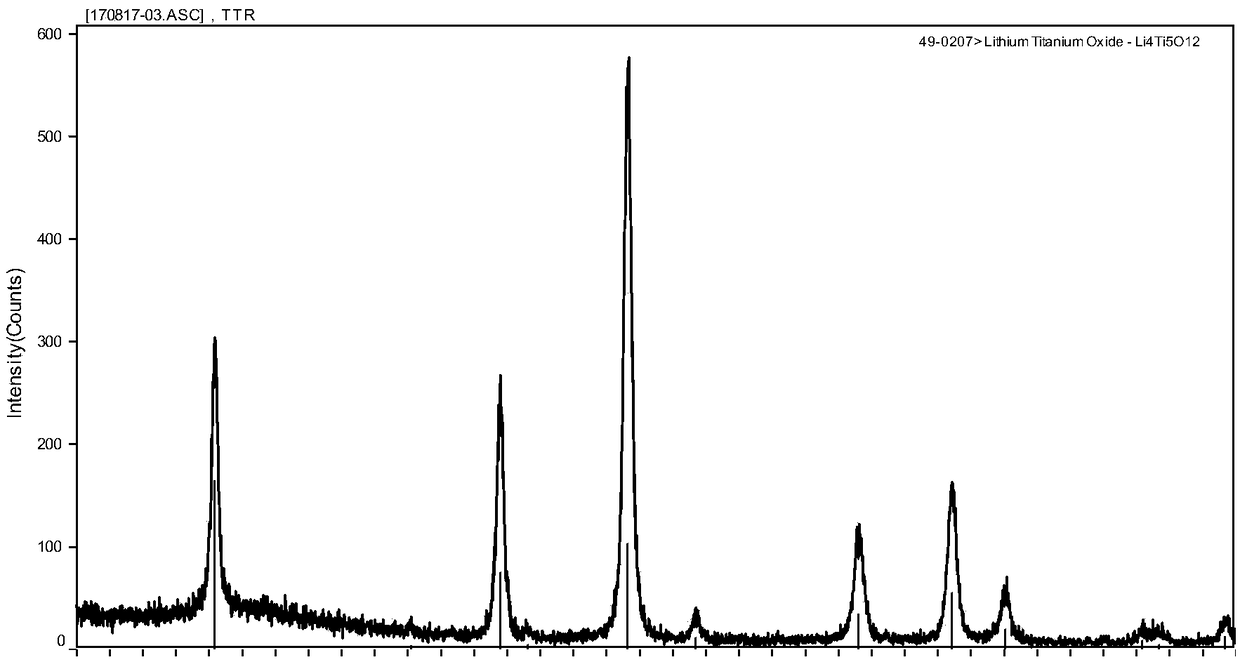

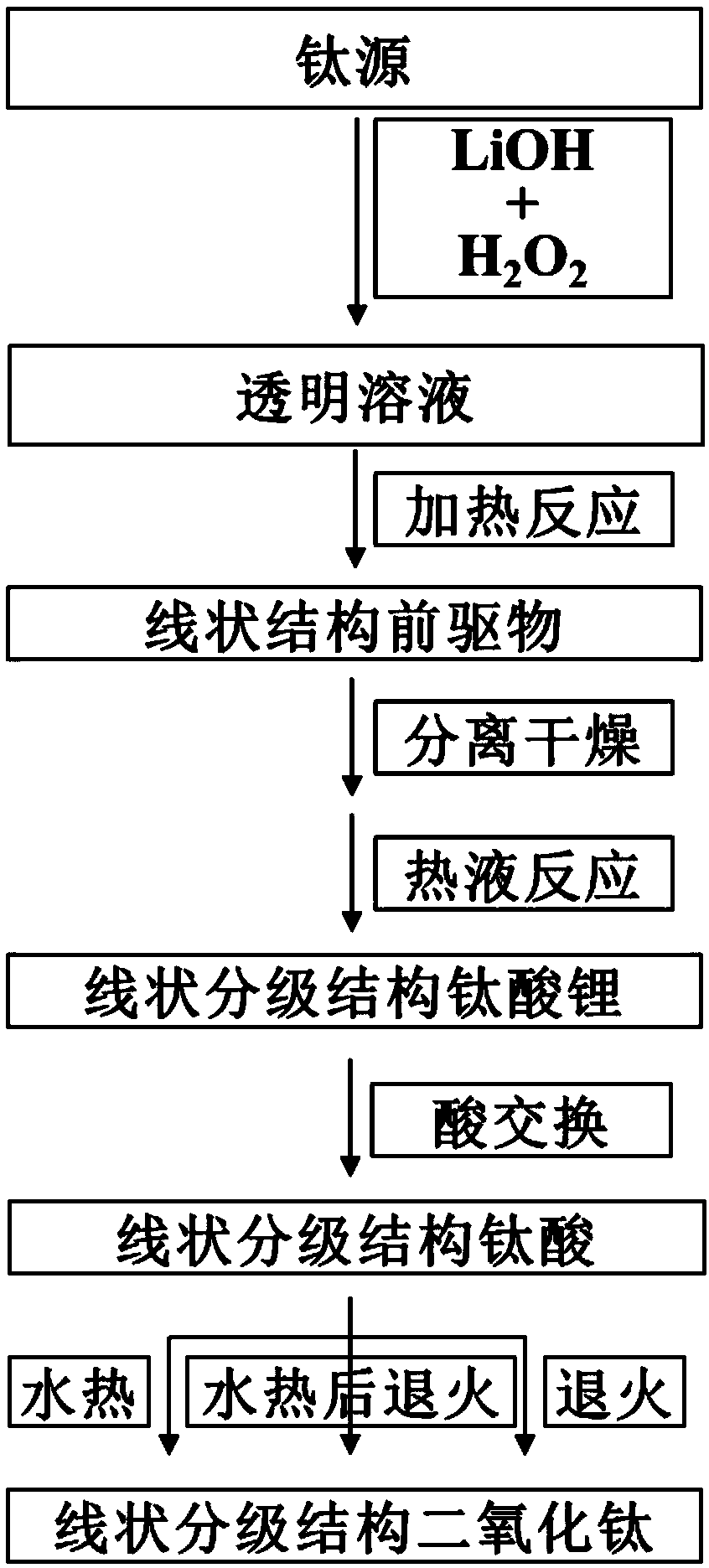

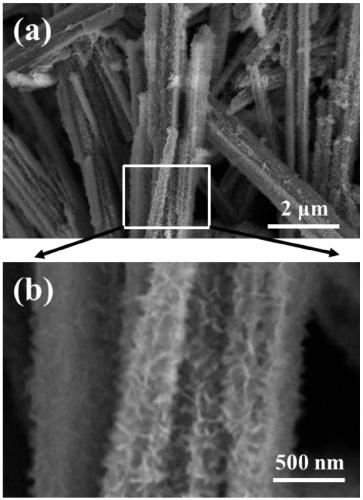

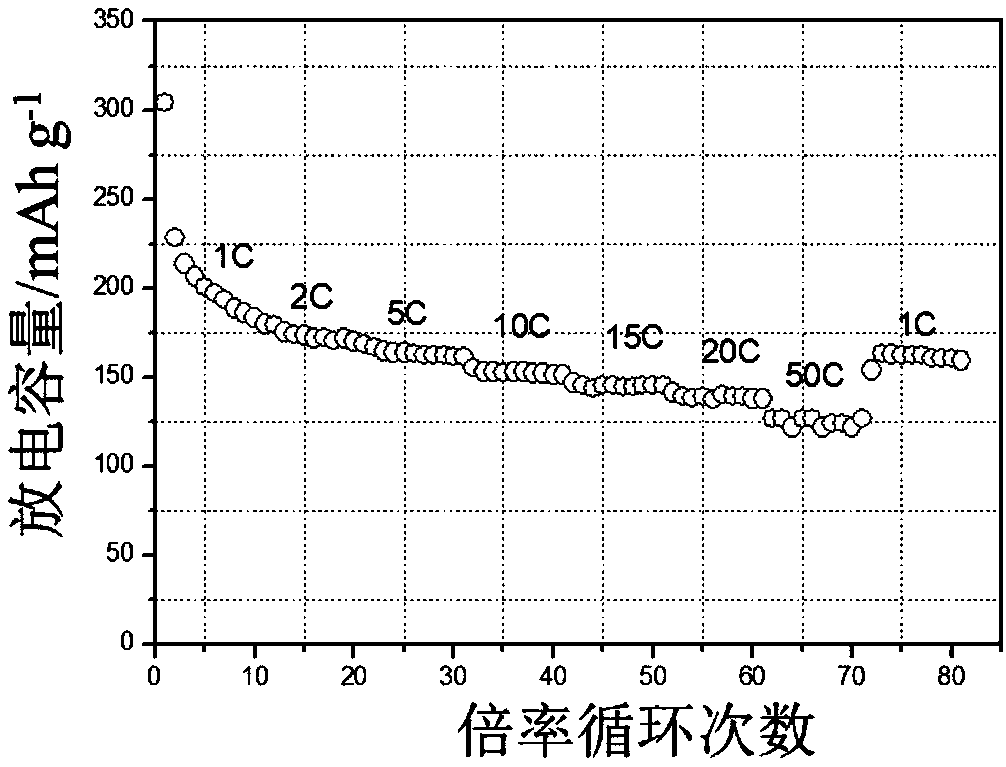

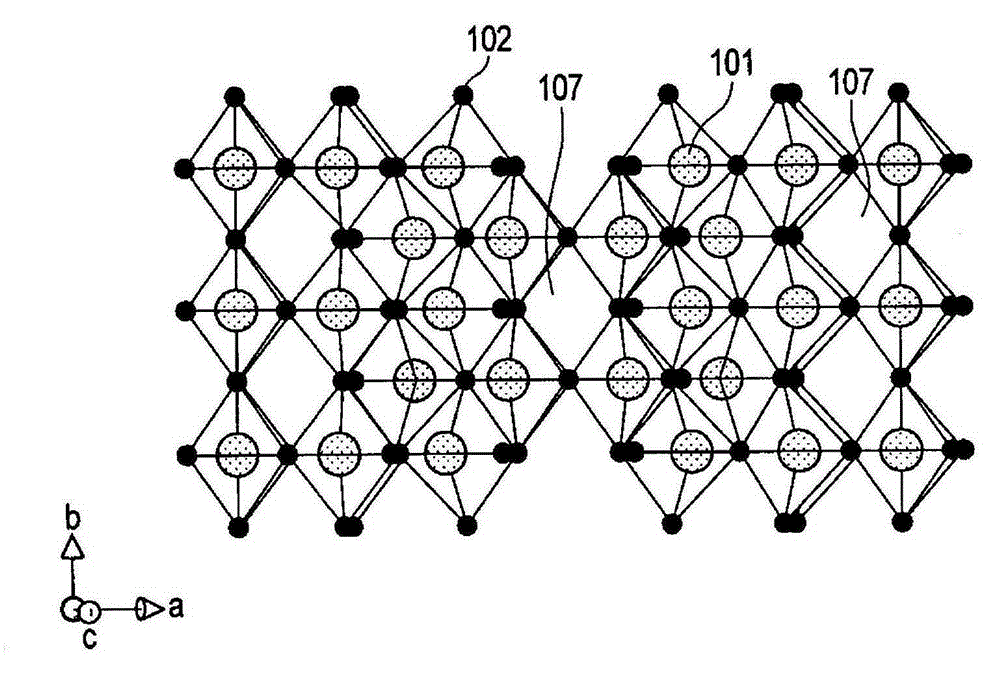

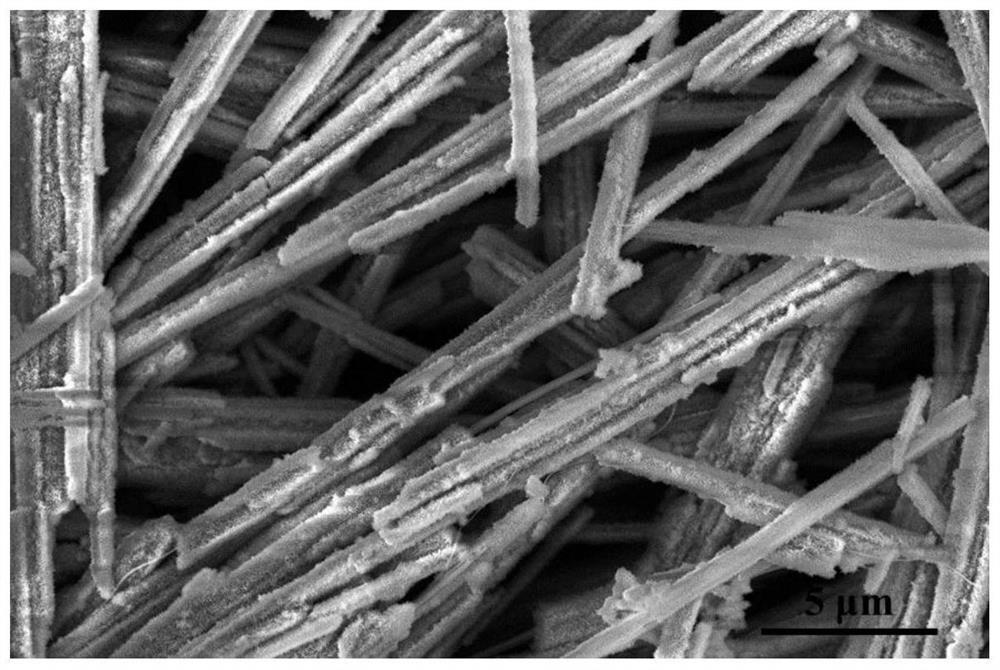

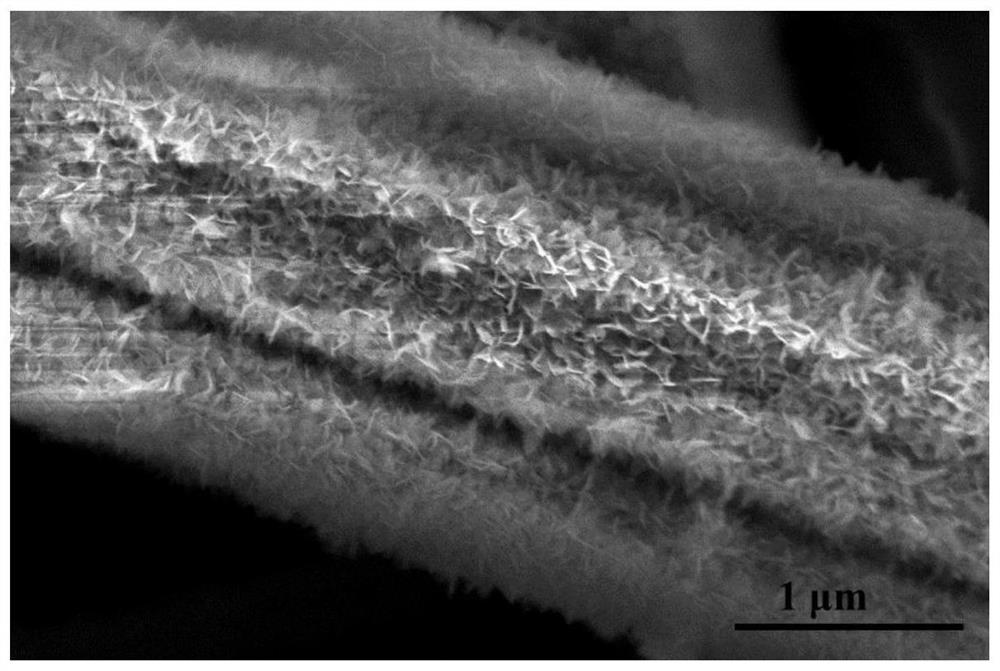

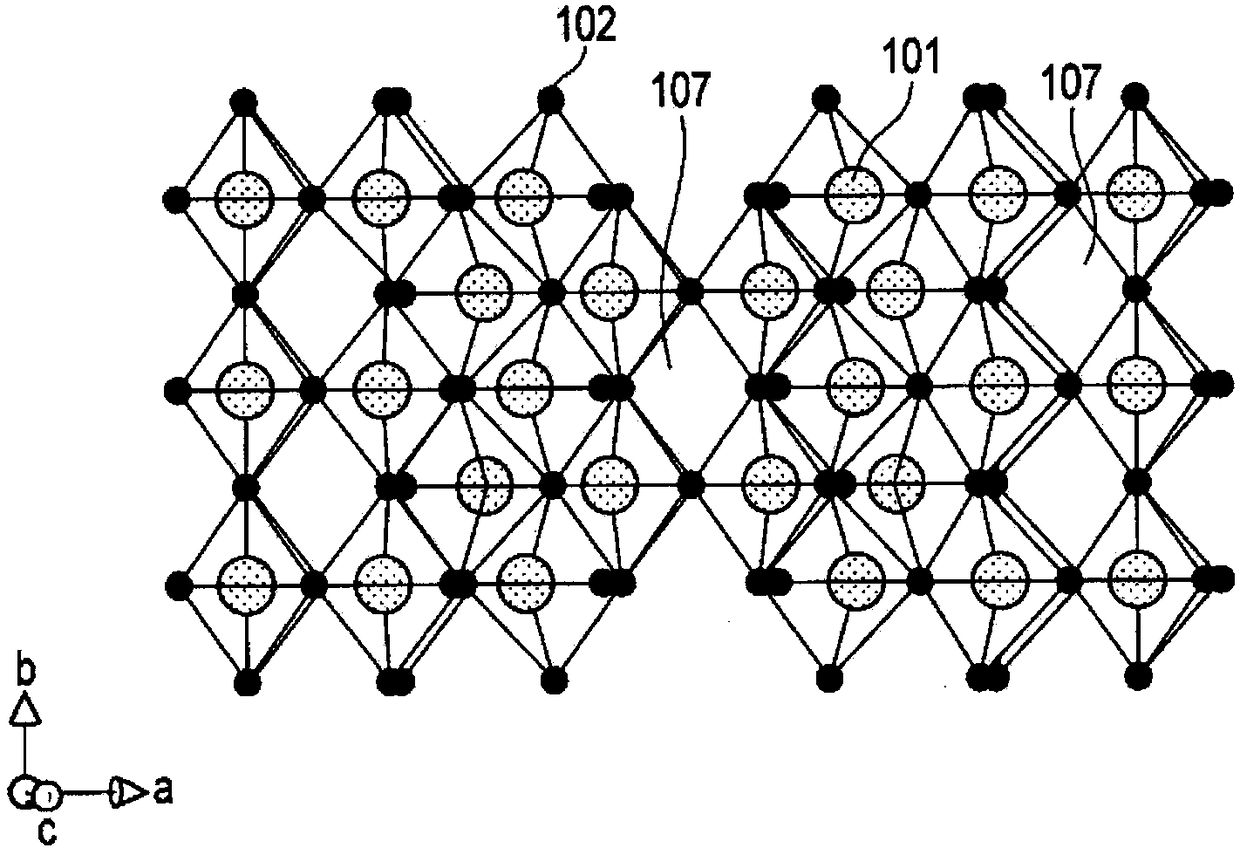

Linear hierarchy lithium titanate material, as well as preparation and application thereof

ActiveCN108946798AFacilitate contact areaQuick contact areaMaterial nanotechnologyAlkali titanatesElectronElectrolyte

The invention provides a linear hierarchy lithium titanate material, as well as preparation and application thereof. The lithium titanate material has a spinel crystal phase, or a monoclinic crystal phase or a composite crystal phase of spinel and monoclinic crystal phases, wherein the lithium titanate material is mainly formed by a linear hierarchy structure which has a draw ratio of more than 10; and the surface of the lithium titanate material with the linear hierarchy structure is formed by nanosheets. According to the linear hierarchy lithium titanate material, the long axis of the linearstructure is favorable to effective mobility of electrons, the flaky hierarchy structure is favorable to the process of quickly embedding in and out lithium ions, sodium ions or potassium ions, a large specific surface area is favorable to the contact area of electrolyte and electrode, the current density is reduced, and the material has relatively good battery quick charge and discharge performance.

Owner:PETROCHINA CO LTD

A kind of preparation method of silicon negative electrode material coated with carbon and lithium titanate double layer

InactiveCN103682268BWell mixedUniform thicknessCell electrodesSecondary cellsNano siliconLithium compound

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

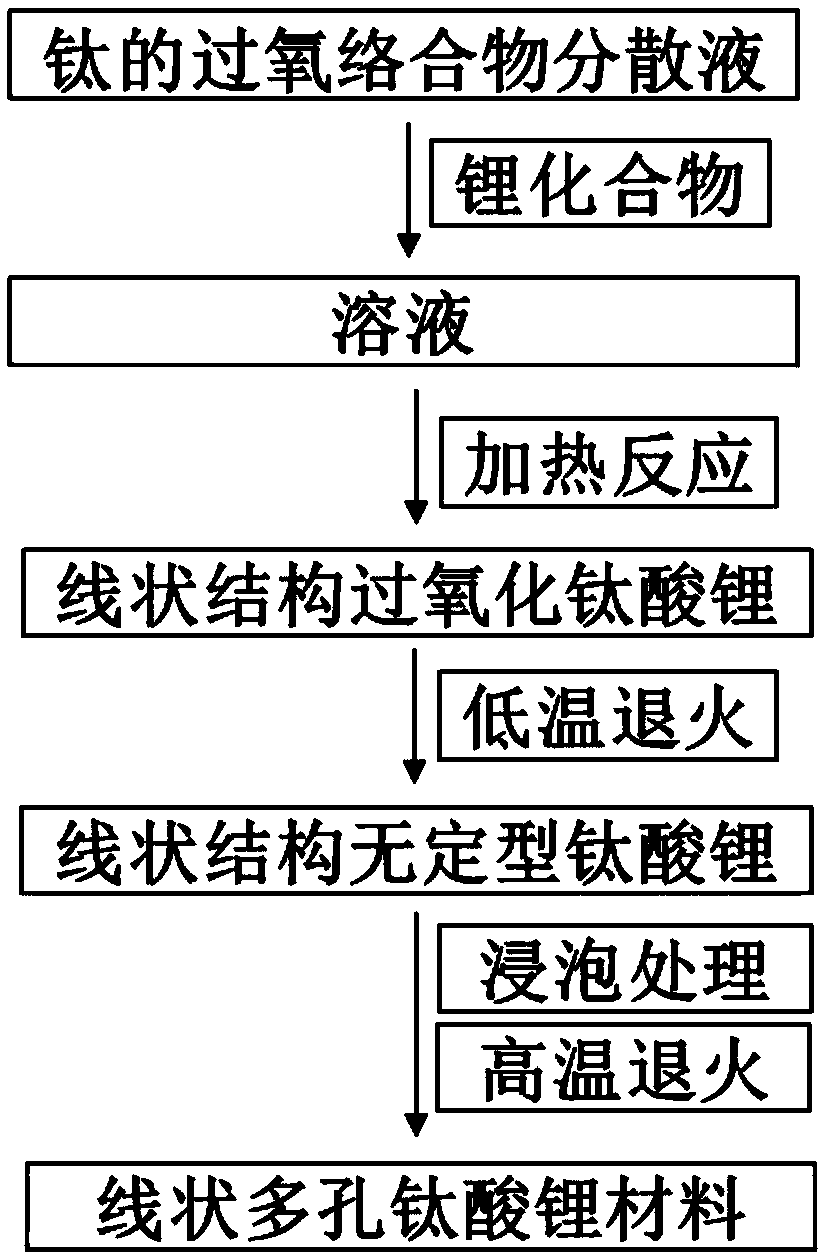

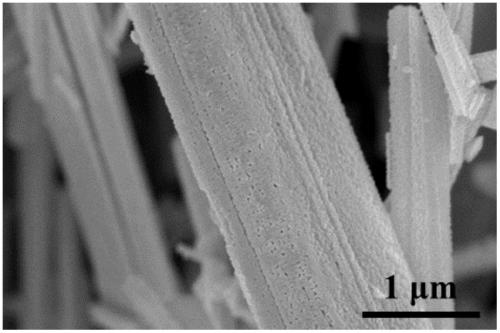

Linear porous lithium titanate material and preparation and product thereof

ActiveCN109326791ALarge specific surface areaIncrease contact areaAlkali titanatesCell electrodesElectrical batteryLong axis

The invention provides a linear porous lithium titanate material and preparation and product thereof. The linear porous lithium titanate material is characterized in that the crystal phase is spinel lithium titanate; the lithium titanate material is of a linear structure; the length to diameter ratio of the linear structure is greater than 10; the linear lithium titanate material is of a porous structure; the structure of the linear porous lithium titanate material consists of a plurality of particles; each particle has the fixed growth direction. The linear porous lithium titanate material has the advantages that the long axis of the structure is suitable for the effective transfer of electrons; the porous structure is suitable for the quick embedding-in and embedding-out process of lithium ions, sodium ions or potassium ions; the large specific surface area is suitable for the contact area between an electrolyte and an electrode, so that the current density is reduced, and the betterbattery quick charge and discharge property is realized.

Owner:PETROCHINA CO LTD

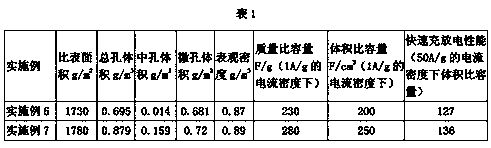

High-volume specific capacity coal-based supercapacitor electrode material and preparation method thereof

ActiveCN108455555AHigh apparent densityLarge specific surface areaHybrid capacitor electrodesCarbon preparation/purificationActivation methodPorous carbon

The invention relates to the technical field of supercapacitor electrode materials, and provides a high-volume specific capacity coal-based supercapacitor electrode material and a preparation method thereof. The high-volume specific capacity coal-based supercapacitor electrode material is obtained in the following steps that coal is crushed to obtain coal powder, and the coal powder and an oxidizing agent are subjected to oxidation treatment to obtain coal oxide; the coal oxide is mixed with potassium hydroxide to obtain a mixture; the obtained mixture is compacted, and the compacted mixture is carbonized to obtain a carbonized sample; the carbonized sample is washed and dried to obtain the supercapacitor electrode material. According to the method, coal wide in source serves as the raw material, and a simple and universal compacting activation method is used for preparing the porous carbon material with high apparent density, high specific surface area and high volume specific capacity, the supercapacitor electrode material has excellent rapid charge and discharge performance, the problem that the volume ratio of a supercapacitor electrode material is not high is solved, and an idea for clean and efficient utilization of coal is provided.

Owner:XINJIANG UNIVERSITY

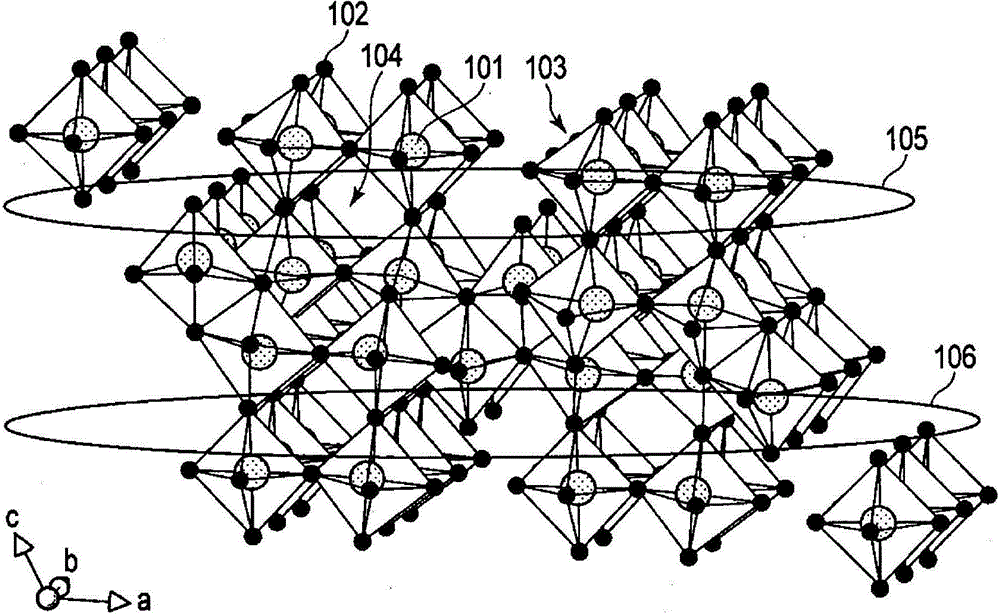

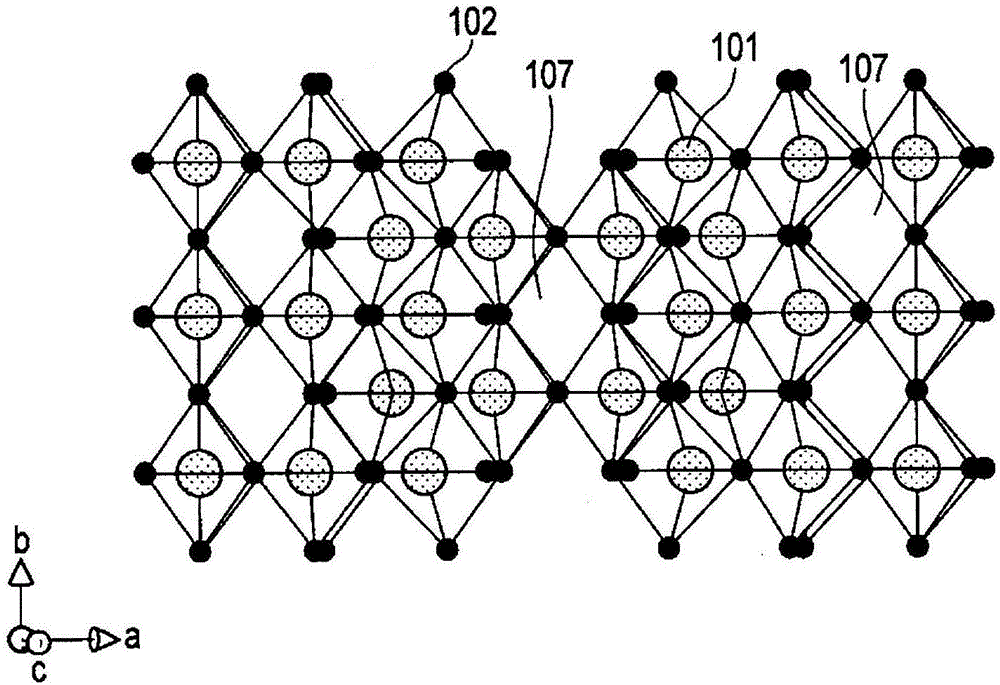

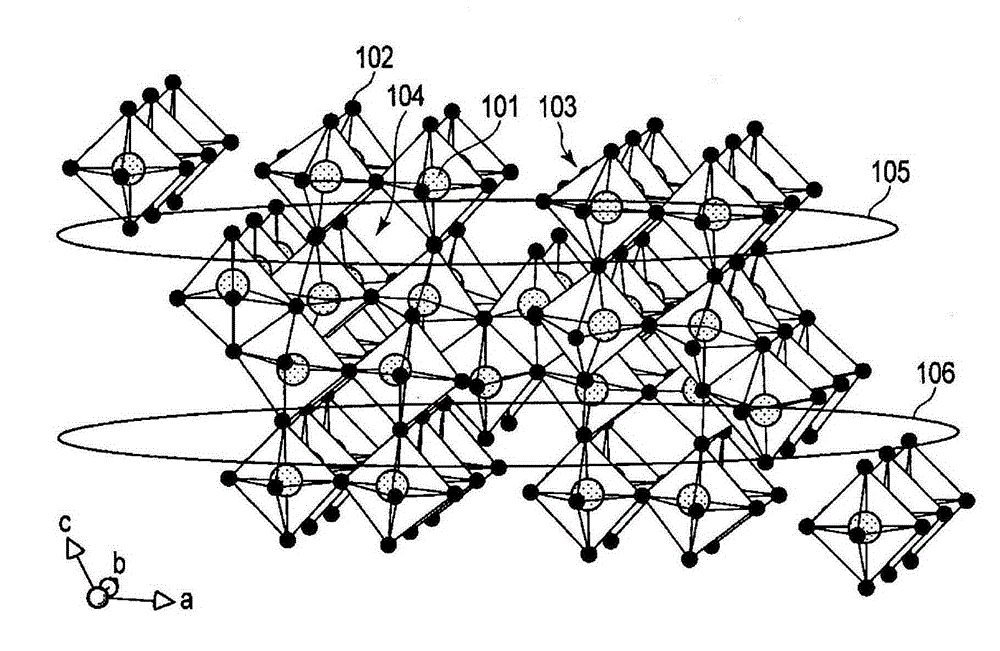

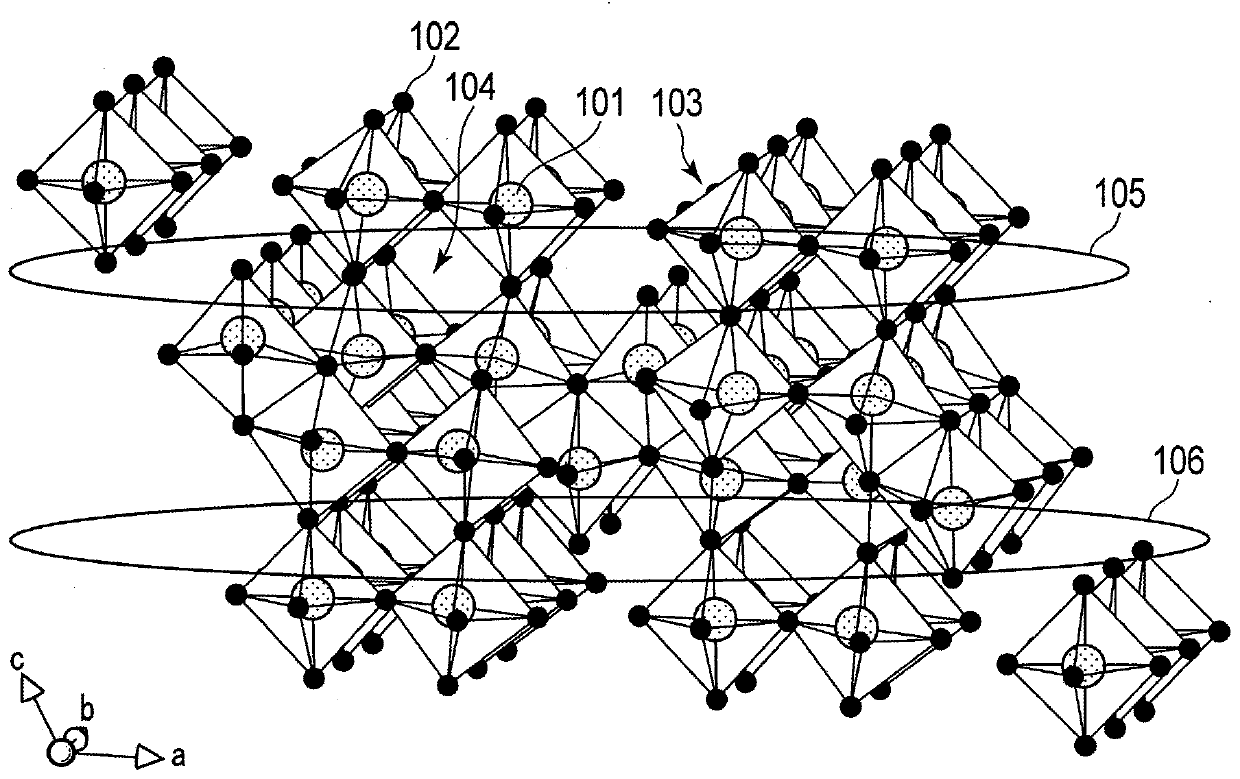

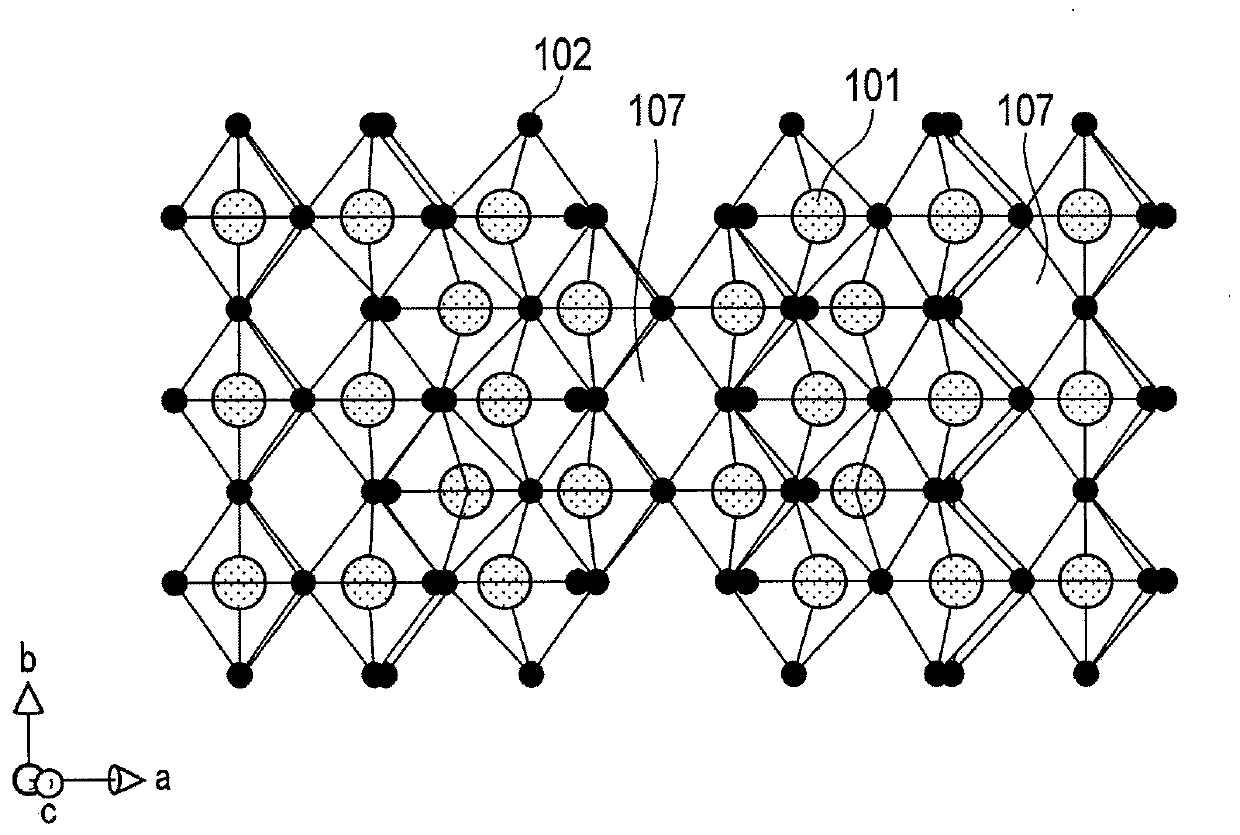

Active material for batteries, non-aqueous electrolyte battery, and battery pack

ActiveCN105102089AExcellent repeated charge and discharge characteristicsGood fast charge and discharge capabilityBatteries circuit arrangementsTantalum compoundsBattery packMetal

According to one embodiment, there is provided an active material. The active material contains a composite oxide represented by the following general: a general formula Lix(Nb1−yTay)2+0.5zTi1−zM0.5zO7 (0≰x≰5, 0≰y≰1, and 0<z≰1). In this formula, M is at least one metal element selected from the group consisting of Sc, Y, V, Cr, Fe, Co, Mn, Al, and Ga.

Owner:KK TOSHIBA

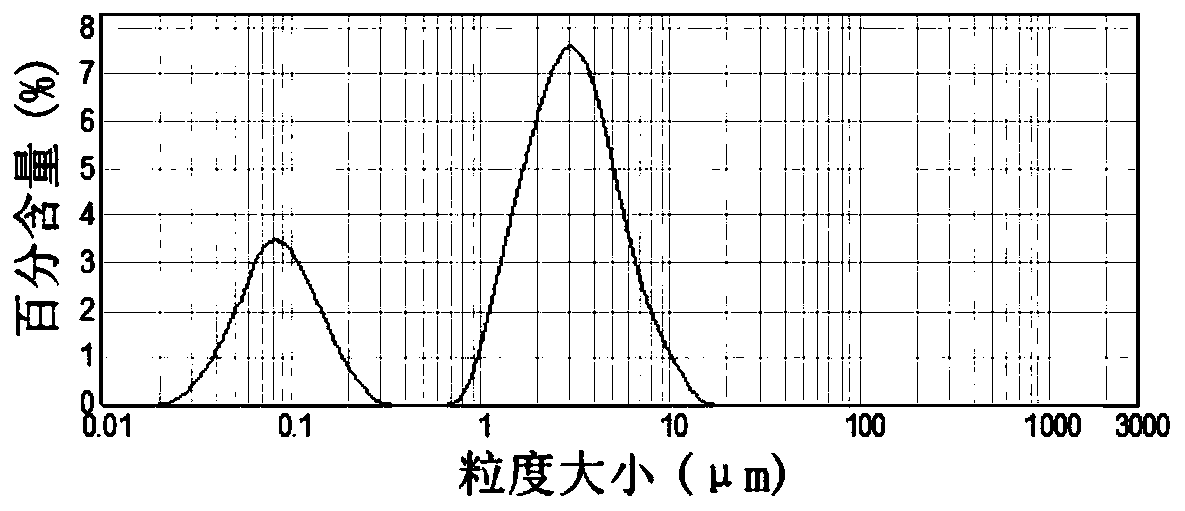

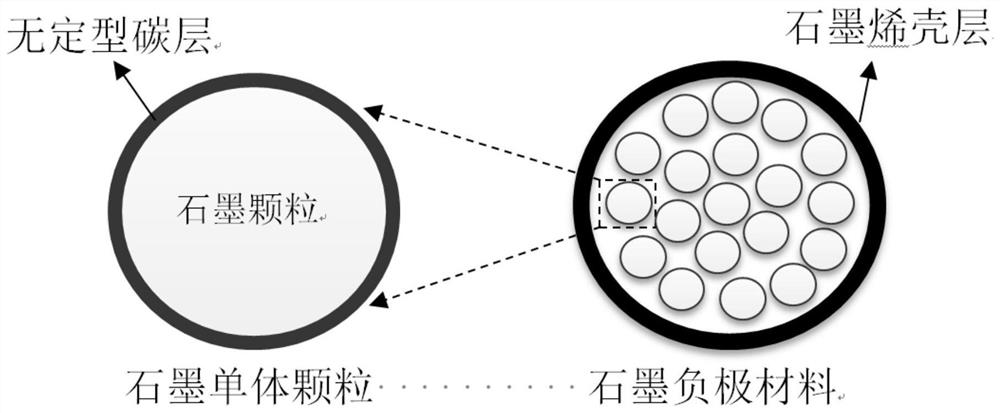

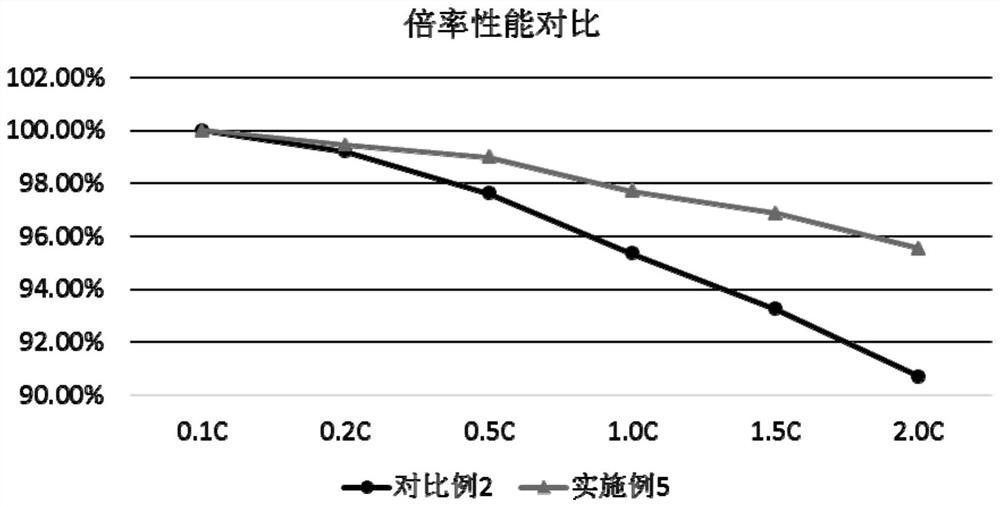

Graphite negative electrode material, preparation method thereof and battery

ActiveCN112786878AImprove cycle stabilityImprove securitySecondary cellsNegative electrodesDischarge efficiencyCarbon layer

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a graphite negative electrode material which is of a pomegranate-like structure and comprises a graphene shell layer and a plurality of graphite monomer particles wrapped in the graphene shell layer, and each graphite monomer particle comprises a graphite particle and an amorphous carbon layer wrapping the outer surface of the graphite particle. According to the graphite negative electrode material, the graphite particles serve as the inner core, the outer surface of the inner core is coated with the amorphous carbon layer to form a graphite monomer particle, the multiple graphite monomer particles are coated with the graphene to form a whole, the whole is a secondary coated particle with the graphene as the shell layer, the whole is of a pomegranate-like structure, the ion transmission path is shortened, the rapid charging and discharging performance of the lithium ion battery is improved, and the cycling stability, the charging and discharging efficiency and the safety performance of the lithium ion battery are improved.

Owner:EVERGRANDE NEW ENERGY TECH SHENZHEN CO LTD

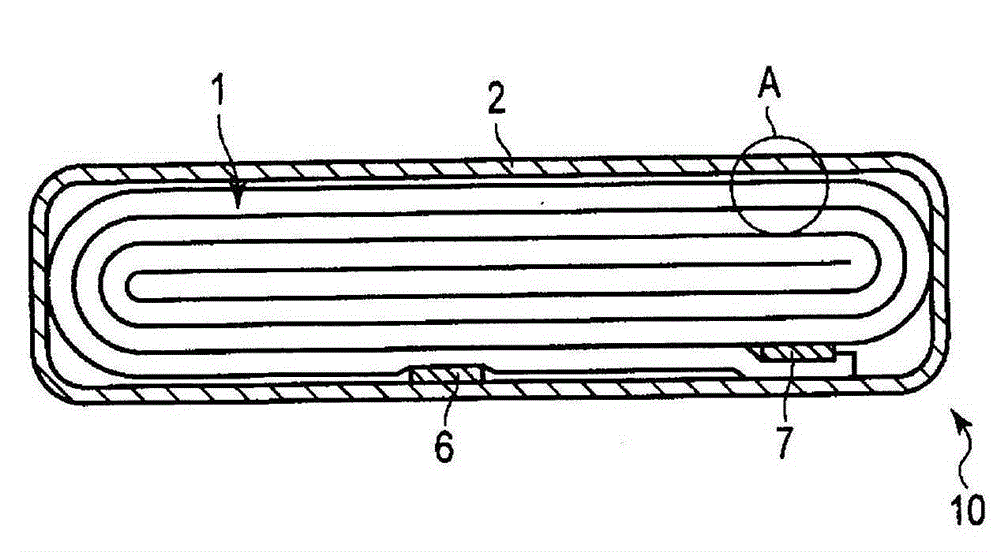

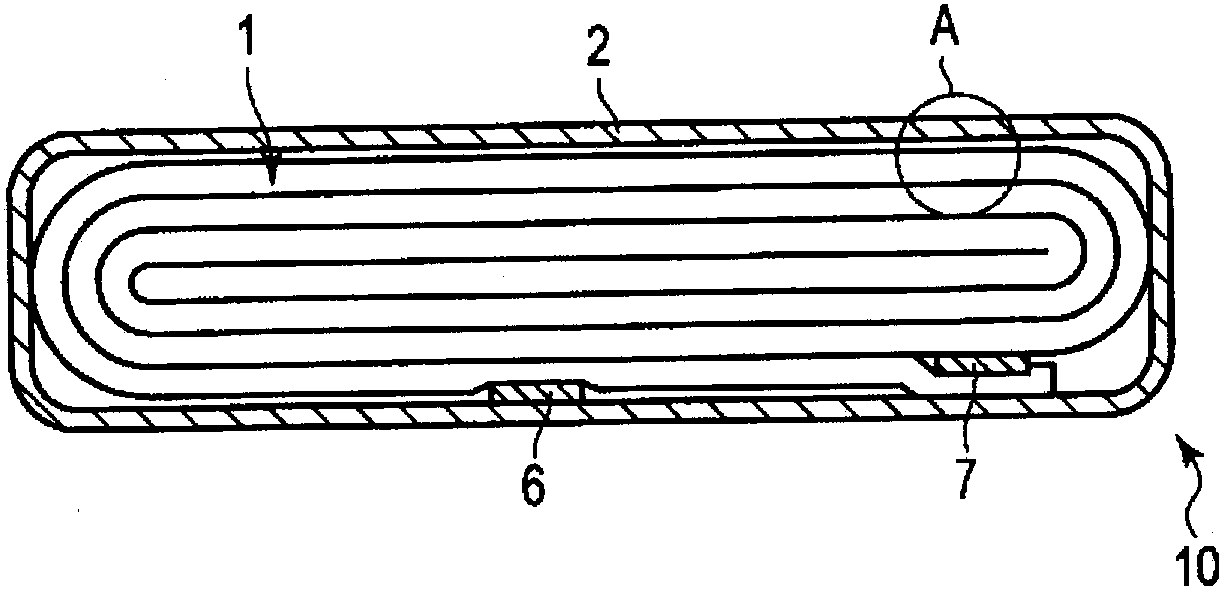

A kind of preparation method of lithium ion battery adopting lithium titanate negative electrode

ActiveCN103682454BOvercome the shortcomings that are not conducive to fast charging and dischargingImprove performanceCell electrodesFinal product manufactureSlurryIonic liquid

The invention discloses a preparation method of a lithium ion battery adopting a lithium titanate cathode. The preparation method comprises the following steps: preparing slurry; making an anode plate and a cathode plate, and assembling into a laminated flexible packaging battery together with a diaphragm; drying and dewatering; filling ionic liquid-containing electrolyte; performing film-forming activation primarily; filling commercial lithium ion battery electrolyte; performing film-forming activation secondarily; storing at high temperature; charging and discharging; degassing; sealing to obtain the lithium ion battery. By the preparation method, a dense and stable composite SEI film with excellent performance can be easily obtained on the surface of an electrode and a swelling phenomenon of the lithium ion battery using the lithium titanate cathode in charging and discharging processes can be effectively prevented; the developed lithium ion battery has the advantages of long cycle life, excellent rapid charging and discharging capacities and high safety.

Owner:CENT SOUTH UNIV

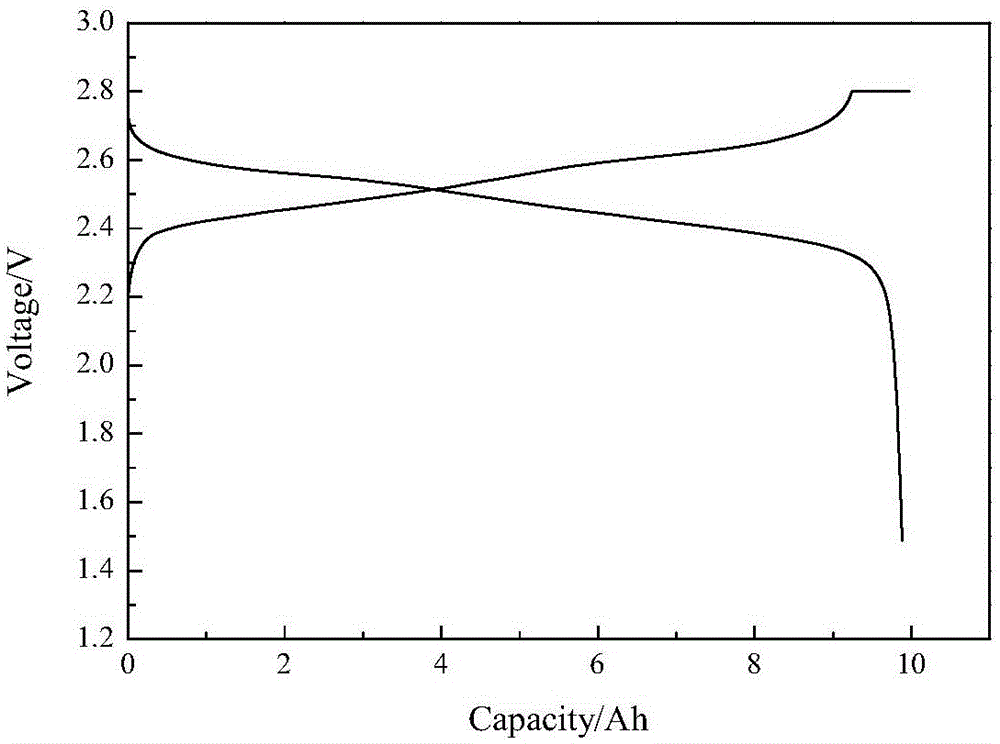

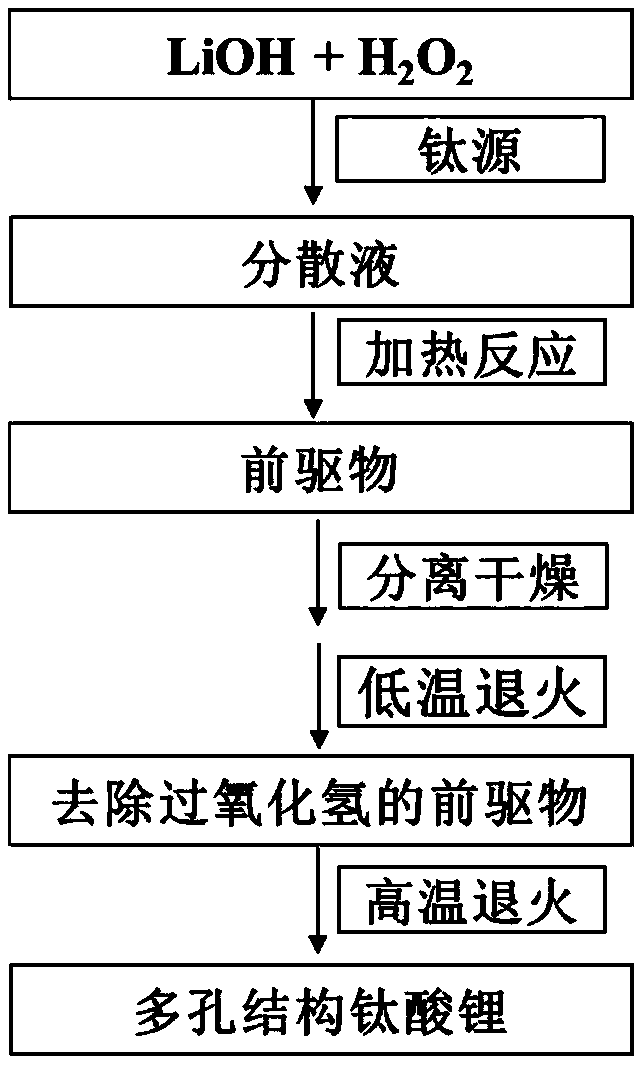

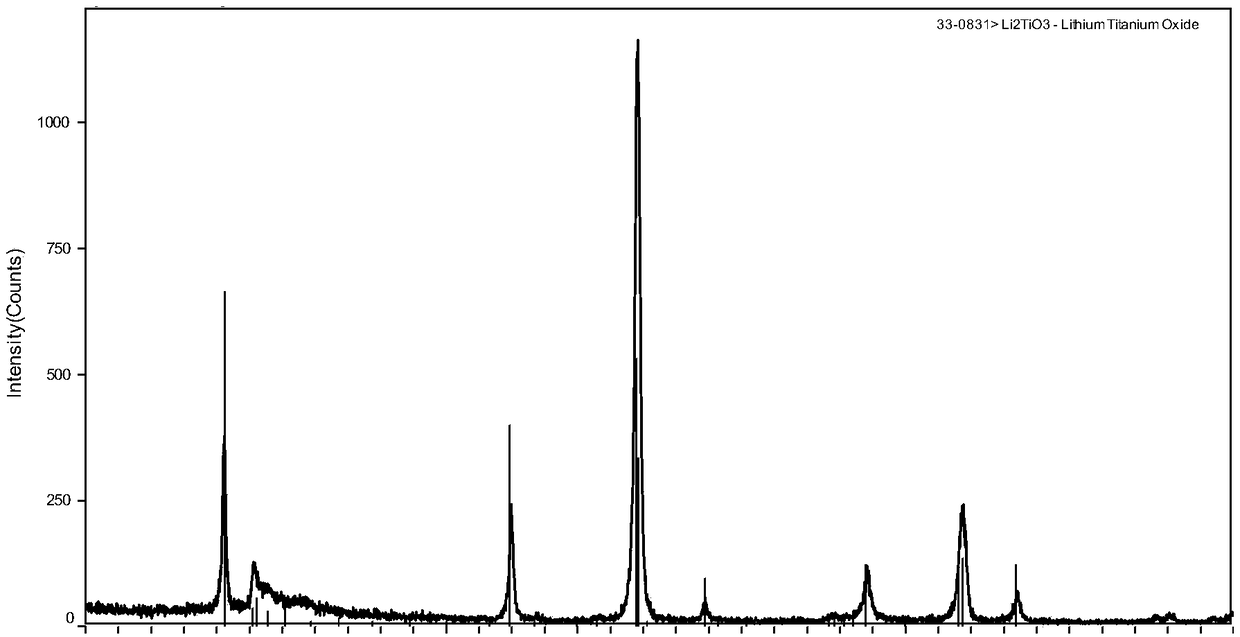

Lithium titanate of porous structure as well as preparation method and application thereof

ActiveCN109319829AAdjustable percentageCrystal phase adjustableAlkali titanatesCell electrodesLithium hydroxideAqueous solution

The invention provides lithium titanate of a porous structure as well as a preparation method and application thereof. The preparation method comprises the following steps of S1, dispersing a titaniumsource into a hydrogen peroxide water solution containing lithium hydroxide to obtain a dispersion solution; S2, performing heating reaction on the dispersion solution obtained in the S1 to obtain precursors; S3, separating and drying the precursors obtained in the S2; S4, performing low-temperature annealing treatment on the dried precursors; S5, performing high-temperature annealing treatment on the precursors subjected to low-temperature annealing treatment in S4 to obtain the lithium titanate of the porous structure. The lithium titanate of a linear porous structure, a linear and regularparticles existence porous structure and a regular particle porous structure can be prepared by the method, and these structures cannot be realized by other methods.

Owner:PETROCHINA CO LTD

Linear grading structure type lithium titanate and preparation method and application thereof

ActiveCN108975390AFacilitate contact areaQuick contact areaAlkali titanatesCell electrodesLithium hydroxidePotassium ions

The invention provides linear grading structure type lithium titanate and a preparation method and application thereof. The preparation method comprises the following steps of (S1) dispersing a titanium source into an aqueous solution of hydrogen peroxide containing lithium hydroxide, so as to obtain a transparent solution; (S2) heating the transparent solution obtained in step (S1) to react, so as to obtain a linear structure type precursor; (S3) separating the linear structure type precursor obtained in step (S2), and drying; (S4) performing heat liquid reaction on the dried linear structuretype precursor in step (S3), so as to obtain the linear grading structure type lithium titanate. The obtained linear grading structure type lithium titanate is suitable for the effective transfer ofelectrons, is suitable for the quick embedding-in and embedding-out process of lithium ions, sodium ions or potassium ions by the grading structure, and is suitable for increasing the contact area between an electrolyte and an electrode by the large specific surface area, and reducing the current density; the better quick charge and discharge property of a battery is realized.

Owner:PETROCHINA CO LTD

Active material for batteries, non-aqueous electrolyte battery, and battery pack

ActiveCN105190962AExcellent repeated charge and discharge characteristicsGood fast charge and discharge capabilityBatteries circuit arrangementsTantalum compoundsComposite oxideBattery pack

According to one embodiment, an active material for batteries is provided. The active material for batteries comprises a composite oxide represented by the general formula: Lix(Nb1-yTay)2-zTi1+0.5zM0.5zO7. In the formula, 0<=x<=5, 0<=y<=1, 0<z<=1, and M represents at least one metal element selected from the group consisting of Mo and W.

Owner:KK TOSHIBA

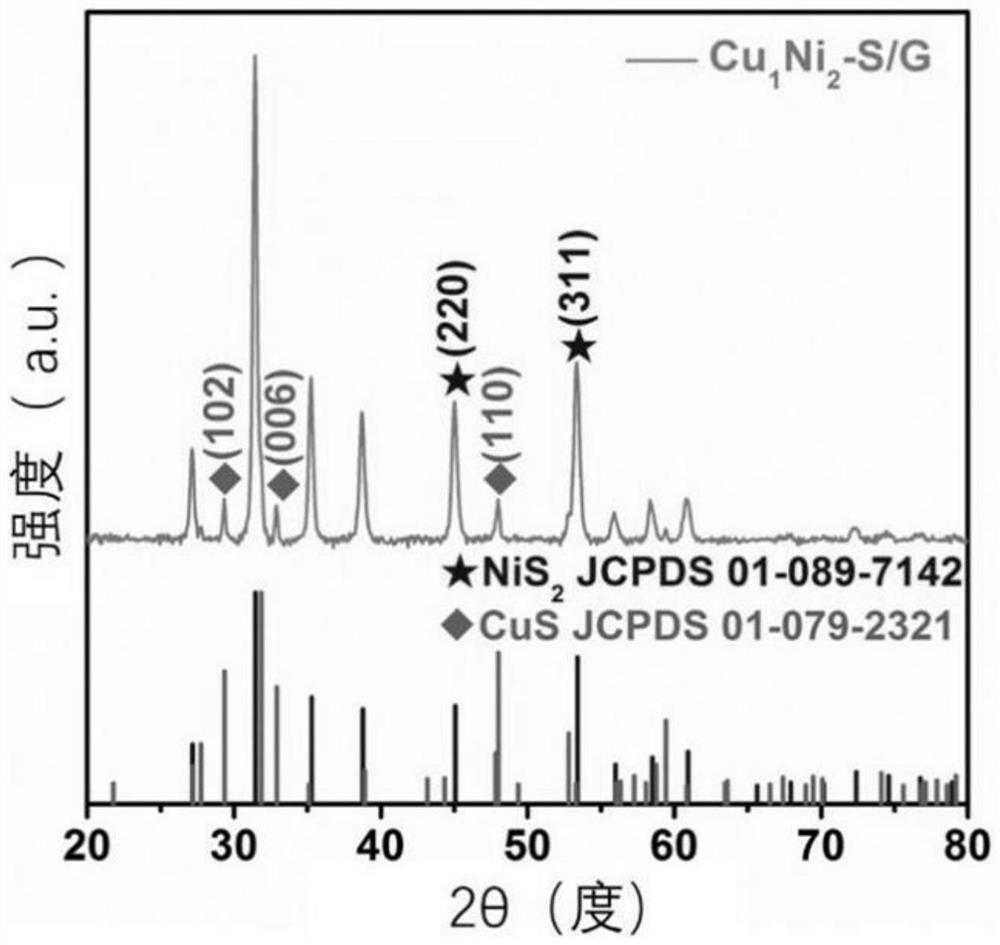

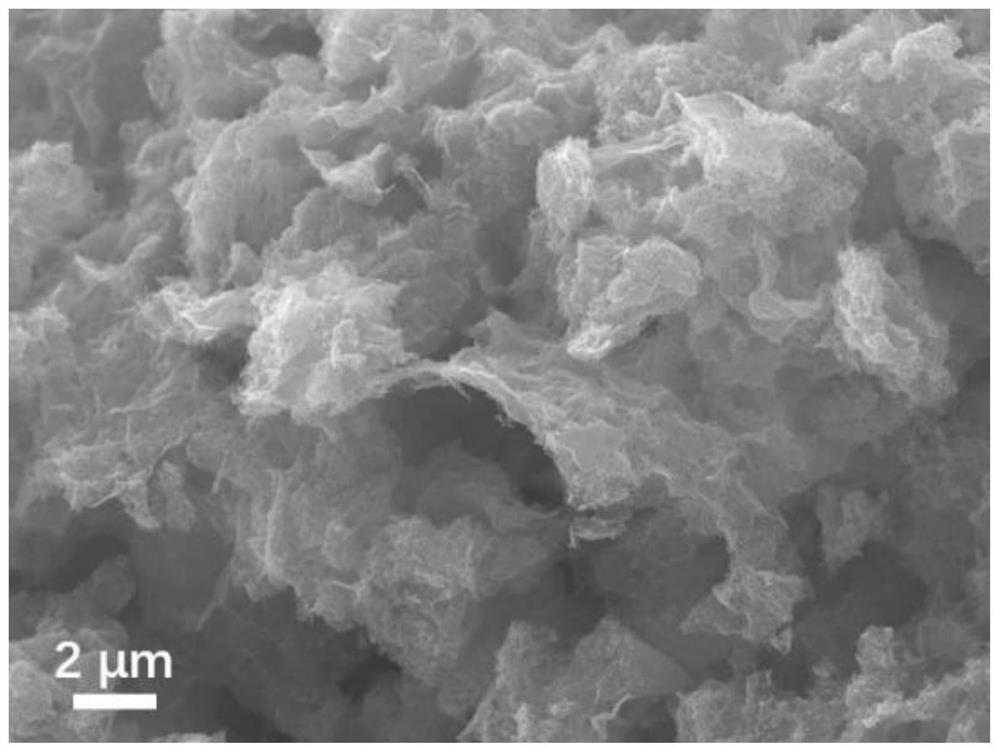

Graphene composite copper sulfide/nickel sulfide catalytic material and preparation method and application thereof

PendingCN113659151AFacilitate adsorption behaviorLower energy barrierFuel and secondary cellsCell electrodesArgon atmosphereCopper nitrate

The invention provides a graphene composite copper sulfide / nickel sulfide catalytic material as well as a preparation method and application thereof. The preparation method comprises the following steps: preparing a graphene oxide dispersion liquid; dissolving copper nitrate, nickel nitrate and urea in deionized water, uniformly performing stirring, adding the graphene dispersion liquid, and uniformly performing mixing to form a mixed solution; placing the mixed solution in a polytetrafluoroethylene reaction kettle, performing hydrothermal reaction, performing cooling to room temperature, performing centrifugal washing with deionized water and ethanol, and performing drying to obtain precursor powder; respectively placing the precursor powder and sulfur powder in two porcelain boats, and performing calcining in an argon atmosphere to obtain the graphene composite copper sulfide / nickel sulfide catalytic material. According to the graphene composite copper sulfide / nickel sulfide catalytic material prepared by the invention, the synergistic effect between strong interface coupling and sulfur vacancies can effectively adjust an electronic structure, the adsorption behavior of an oxygen intermediate is promoted, and the graphene composite copper sulfide / nickel sulfide catalytic material shows excellent and efficient oxygen reduction and alcohol oxidation dual-function catalytic performance.

Owner:WUHAN UNIV OF TECH

Method for the preparation of high rate lithium ion capacitor battery cathode material by pyrolyzing asphalt at low temperature to cover graphite

InactiveCN101604748BImprove charge and discharge efficiencyImprove the degree of graphitizationElectrode manufacturing processesCapacitanceAlcohol

Owner:CENT SOUTH UNIV

Technology for processing anode material of cell

InactiveCN102556995AGood physical propertiesGood chemical propertiesPhosphorus compoundsChemical industryMaterials science

The invention which belongs to the technical field of the chemical industry concretely relates to a technology for processing an anode material of a cell. The technology for processing the anode material of the cell has the advantages of simple operation and convenience for the enlarged production. The invention adopts the following technical scheme: a template-high temperature solid phase technique is utilized to process the anode material of the cell in the invention, and the technology of the invention comprises steps of burdening, material mixing, drying, burning, ball milling, sieving, homogenizing and packaging.

Owner:舒品

A linear hierarchical structure lithium titanate material and its preparation and application

ActiveCN108946798BFacilitate contact areaQuick contact areaMaterial nanotechnologyAlkali titanatesElectrolytic agentElectrical battery

The invention provides a lithium titanate material with a linear hierarchical structure and its preparation and application. The crystal phase of the lithium titanate material is a spinel crystal phase, or a monoclinic crystal phase or their composite crystal phase; the lithium titanate material is mainly composed of a linear hierarchical structure; the linear graded The aspect ratio of the structure is greater than 10; the surface constituents of the lithium titanate material of the linear hierarchical structure are nanosheets. The long axis of the linear structure is conducive to the effective transfer of electrons, the sheet-like hierarchical structure is conducive to the rapid intercalation and intercalation of lithium ions, sodium ions or potassium ions, and the large specific surface area is conducive to the contact area between the electrolyte and the electrode, reducing The current density has better battery rapid charge and discharge performance.

Owner:PETROCHINA CO LTD

Active material for battery, non-aqueous electrolyte battery and battery pack

ActiveCN105102089BExcellent repeated charge and discharge characteristicsGood fast charge and discharge capabilityBatteries circuit arrangementsTantalum compoundsComposite oxideBattery pack

An active material for batteries according to one embodiment includes a composite oxide represented by the general formula: Lix(Nb1-yTay)2+0.5zTi1-zM0.5zO7 (0≤x≤5, 0≤y≤1, 0 <z≤1). In the formula, M is at least one metal element selected from the group consisting of Sc, Y, V, Cr, Fe, Co, Mn, Al and Ga.

Owner:KK TOSHIBA

Negative electrode material for power lithium-ion battery with core-shell structure and preparation method thereof

InactiveCN103811717BImprove lithium intercalation capacityAdaptableCell electrodesSecondary cellsCarbonizationCarbide

Owner:XINXIANG SAIRI NEW ENERGY SCI & TECH

Electrodes, non-aqueous electrolyte batteries, battery packs and vehicles

ActiveCN106953067BGood fast charge and discharge capabilityIncrease energy densityCell electrodesSecondary cellsPhysical chemistryEngineering

The invention provides an electrode, a nonaqueous electrolyte battery, a battery pack and a vehicle. Electrodes are provided according to an embodiment. The surface composition ratio (Li+C+O) / P of the electrode measured by X-ray photoelectron spectroscopy XPS is within the range of 2 to 14.

Owner:KK TOSHIBA

A kind of fast charge and discharge high voltage lithium ion battery and preparation method thereof

ActiveCN104681860BIncrease energy densityGood fast charge and discharge capabilityCell electrodesFinal product manufactureFast chargingEngineering

The purpose of the present invention is to provide a high-voltage lithium-ion battery capable of rapid charging and discharging and a preparation method thereof. The battery includes a negative electrode, a positive electrode, a diaphragm between the positive and negative electrodes, and a non-aqueous electrolyte, and the charging cut-off voltage is raised to 4.35V. The energy density of the battery is greatly improved. The present invention is characterized in that the negative electrode material takes graphite as the core, and the graphite surface is evenly coated with a layer of lithium titanate, and then a layer of conductive agent is coated on the surface of graphite particles coated with lithium titanate to form graphite-lithium titanate-conductive agent three-layer composite structure. The manufactured battery has very good fast charging and discharging performance, and the high and low temperature performance has been greatly improved, and the safety performance has also been greatly improved.

Owner:HIGHPOWER TECH HUIZHOU +3

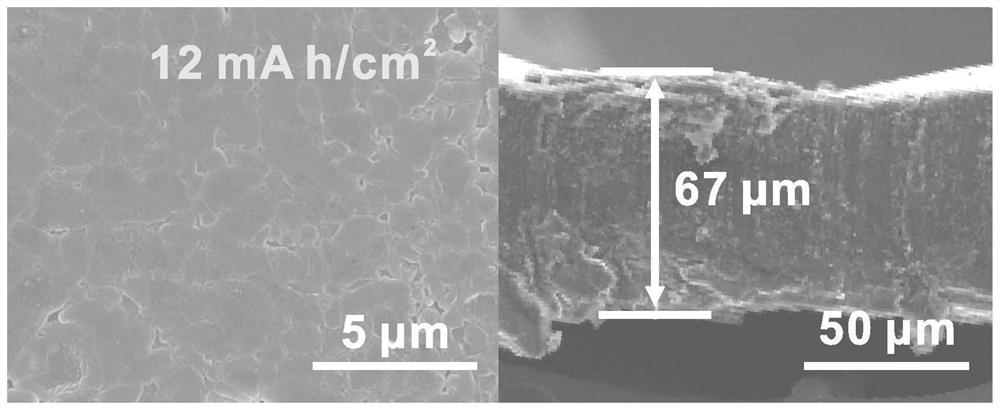

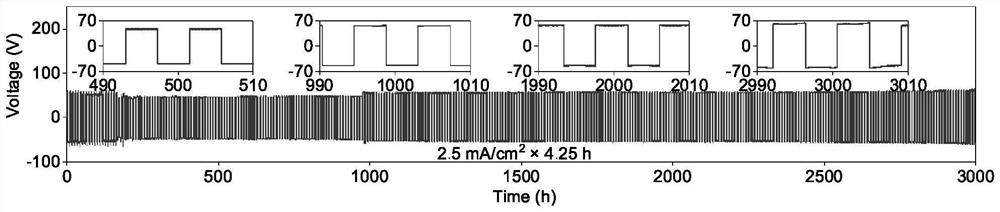

A three-dimensional current collector, metal lithium negative electrode and primary/secondary battery for primary/secondary battery lithium metal negative electrode

ActiveCN110444767BImprove long cycle stabilityGrowth inhibitionElectrode manufacturing processesNon-aqueous electrolyte cellsMetallic lithiumCarbon nanotube

Owner:UNIV OF SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com