High-volume specific capacity coal-based supercapacitor electrode material and preparation method thereof

A technology for supercapacitors and electrode materials, applied in the field of high volume ratio capacity coal-based supercapacitor electrode materials and its preparation, can solve the problems of low volume ratio capacity of supercapacitor electrode materials, and achieve excellent fast charge and discharge performance, high volume ratio The effect of capacity and high apparent density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

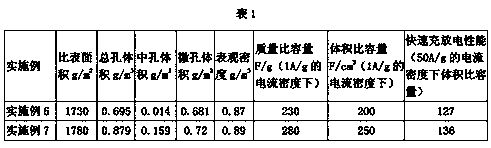

Examples

Embodiment 1

[0017] Embodiment 1: The high volume specific capacity coal-based supercapacitor electrode material is characterized in that it is obtained according to the following steps: the first step, the coal is pulverized, and after sieving treatment, coal powder is obtained, and the coal powder and the oxidant are oxidized , to obtain oxidized coal; the second step is to mix the required amount of oxidized coal and potassium hydroxide in a mass ratio of 1:0 to 4 to obtain a mixture; the third step is to compact the obtained mixture and use nitrogen as a protection The compacted mixture is carbonized, and the temperature is programmed to rise at a rate of 5°C / min from room temperature to 500°C to 1200°C to obtain a carbonized sample; in the fourth step, the carbonized sample is washed with deionized water to the washing solution When it is neutral, the washed carbonized sample is dried to obtain a high volume specific capacity coal-based supercapacitor electrode material.

[0018] The ...

Embodiment 2

[0020] Embodiment 2: The high volume specific capacity coal-based supercapacitor electrode material is characterized in that it is obtained according to the following steps: the first step, the coal is pulverized, and after sieving treatment, coal powder is obtained, and the coal powder and the oxidant are oxidized , to obtain oxidized coal; the second step is to mix the required amount of oxidized coal and potassium hydroxide in a mass ratio of 1:0.1 or 3 to obtain a mixture; the third step is to compact the obtained mixture and use nitrogen as a protection gas, carbonize the compacted mixture, and program the temperature at a rate of 5°C / min from room temperature to 500°C or 1200°C to obtain a carbonized sample; the fourth step is to wash the carbonized sample with deionized water until the washing liquid When it is neutral, the washed carbonized sample is dried to obtain a high volume specific capacity coal-based supercapacitor electrode material.

Embodiment 3

[0021] Embodiment 3: As an optimization of the above embodiment, the oxidizing agent is a mixed solution of concentrated sulfuric acid and concentrated nitric acid, wherein, in the mixed solution, the volume ratio of concentrated sulfuric acid and concentrated nitric acid is 3:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com