A kind of preparation method of lithium ion battery adopting lithium titanate negative electrode

A lithium-ion battery and lithium titanate technology, which is applied in the field of electrochemistry, can solve the problems of easy gas expansion of lithium titanate, and achieve the effects of preventing gas swelling, excellent rapid charge and discharge ability, and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

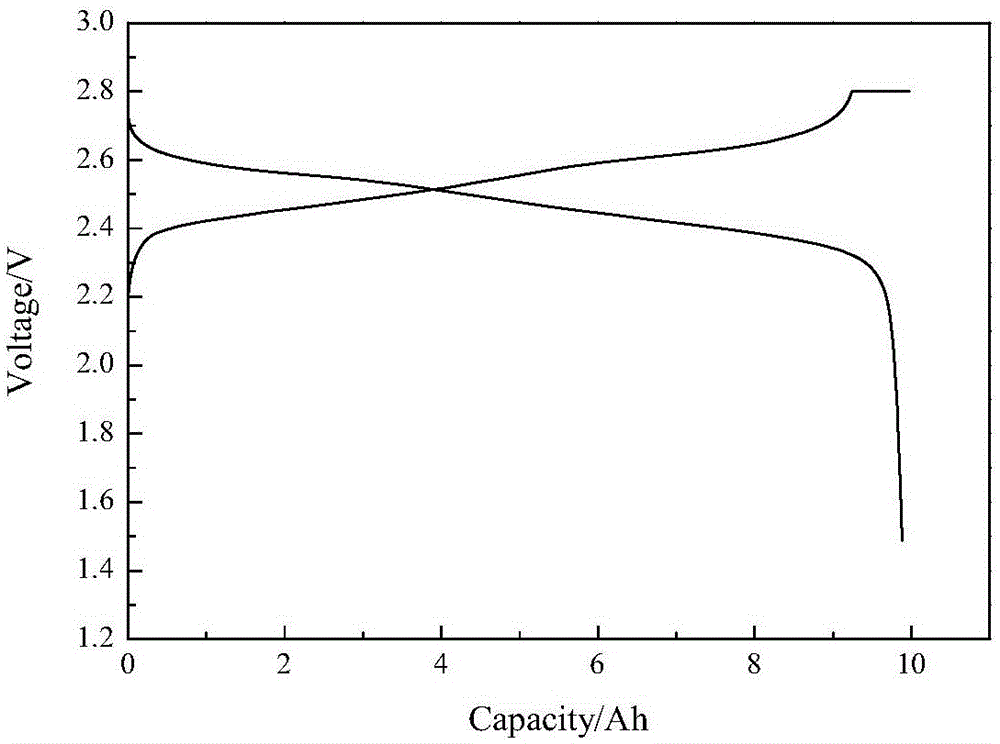

Image

Examples

Embodiment 1

[0043] Lithium manganate is used as the positive electrode active material of lithium ion batteries, mixed with binders, conductive agents, additives, solvents, etc. to prepare lithium manganate positive electrode slurry. Cut to get the positive electrode sheet.

[0044] Lithium titanate is used as the negative electrode active material, mixed with binder polyvinylidene fluoride, Super P conductive carbon, and additive phosphorus flake graphite at a mass ratio of 90:5:3:2, and mixed with solvent N-methylpyrrolidone, etc. Negative electrode slurry, current collector is copper foil, coated according to the ratio of negative electrode capacity to positive electrode capacity of 0.95, dried, rolled and punched to obtain negative electrode sheet.

[0045] The positive electrode sheet, negative electrode sheet and separator are combined by lamination, and assembled with composite tabs and aluminum-plastic film to form a 1072170 (thickness 10mm, width 72mm, length 170mm) type lithium ...

Embodiment 2

[0052] Lithium cobalt oxide is used as the positive electrode active material of lithium ion battery, mixed with binder, conductive agent, additive, solvent, etc. Positive sheet.

[0053] Lithium titanate is used as the negative electrode active material, mixed with binder polyvinylidene fluoride, Super P conductive carbon, and additive phosphorus flake graphite at a mass ratio of 95:3:2, and mixed with solvent N-methylpyrrolidone to prepare negative electrode slurry The current collector is copper foil, which is coated according to the ratio of the negative electrode capacity to the positive electrode capacity of 0.97, and then dried, rolled, and punched to obtain the negative electrode sheet.

[0054] The positive electrode sheet, negative electrode sheet and separator are combined by lamination, and assembled with composite tabs and aluminum-plastic film to form a 1072170 (thickness 10mm, width 72mm, length 170mm) type lithium titanate negative lithium-ion battery, nominal ...

Embodiment 3

[0061] Lithium nickel cobaltate is used as the positive electrode active material of lithium-ion batteries, mixed with binders, conductive agents, additives, solvents, etc. Get the positive electrode.

[0062] Lithium titanate is used as the negative electrode active material, mixed with binder polyvinylidene fluoride, Super P conductive carbon, and additive phosphorus flake graphite at a mass ratio of 93:4:2:1, and mixed with solvent N-methylpyrrolidone, etc. Negative electrode slurry, current collector is copper foil, coated according to the ratio of negative electrode capacity to positive electrode capacity of 0.97, dried, rolled and punched to obtain negative electrode sheet.

[0063] The positive electrode sheet, negative electrode sheet and separator are combined by lamination, and assembled with composite tabs and aluminum-plastic film to form a 1072170 (thickness 10mm, width 72mm, length 170mm) type lithium titanate negative lithium-ion battery, nominal Capacity 12Ah....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com