Graphite negative electrode material, preparation method thereof and battery

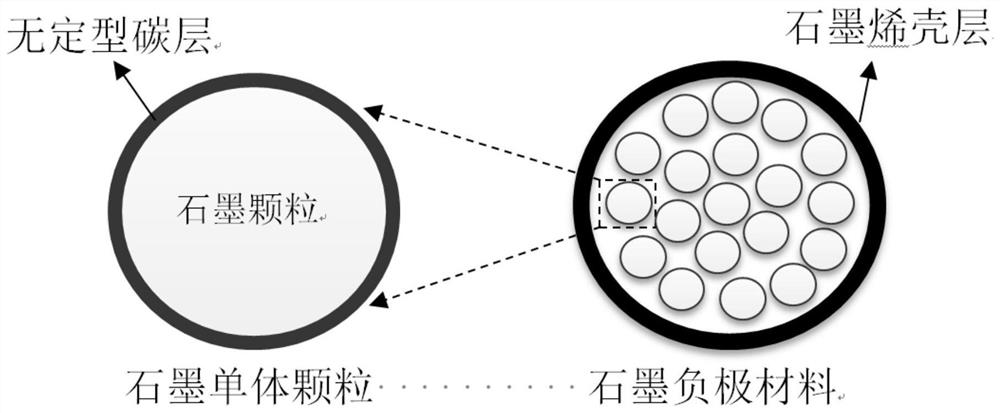

A graphite negative electrode and graphite technology, applied in the direction of negative electrodes, battery electrodes, secondary batteries, etc., can solve problems such as poor charge and discharge performance, poor cycle stability, and electrode sheet shedding, and achieve volume expansion and contraction inhibition and force enhancement. , to avoid the effect of capacity drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The embodiment of the present invention also provides a preparation method of a graphite negative electrode material, comprising the following steps:

[0049] S10. After dispersing graphite, carbon source and graphene in water, grind to obtain a grind product;

[0050] S20. Spray granulating the ground product to obtain a graphite negative electrode precursor;

[0051] S30. heat-treating the graphite negative electrode precursor in a protective gas atmosphere at a temperature of 500-1500° C. for 2-48 hours to obtain a graphite negative electrode material with a pomegranate-like structure.

[0052] The preparation method of the graphite negative electrode material provided by the embodiment of the present invention is to disperse graphite, carbon source and graphene in water and then grind the graphite to make the graphite micronano to obtain the ground product. Coating, and the intermolecular force of small-particle graphite is enhanced, and the aggregation of small-pa...

Embodiment 1

[0072] A graphite negative electrode material, comprising the following preparation steps:

[0073] According to the mass ratio of natural graphite, sucrose, sulfonated graphene and pure water as 100:20:1:100, the natural graphite, sucrose and sulfonated graphene were dispersed in pure water, and then ground in a sand mill to obtain an average The particle size D50 is a ground product of 10 μm. Among them, the average particle size D50 of natural graphite is 50 μm; the radial size of sulfonated graphene is 0.05 μm, the thickness is 0.5 nm, and the molar ratio of carbon element and sulfur element in sulfonated graphene is 5:1;

[0074] Under the conditions that the rotating speed of the atomizing disc is 15000rpm and the drying temperature is 250°C, the grinding product with a solid content of 30wt% is spray-granulated to obtain a graphite negative electrode precursor;

[0075] The graphite negative electrode precursor was sintered in a nitrogen atmosphere furnace at 1500° C. ...

Embodiment 2

[0077] A graphite negative electrode material, comprising the following preparation steps:

[0078] According to the mass ratio of natural graphite, glucose, sulfonated graphene and pure water as 10:1:1:100, natural graphite, sucrose and sulfonated graphene were dispersed in pure water, and then ground in a sand mill to obtain an average The ground product with a particle size D50 of 0.1 μm. Among them, the average particle size D50 of natural graphite is 5 μm; the radial size of sulfonated graphene is 100 μm, the thickness is 20 nm, and the molar ratio of carbon element and sulfur element in sulfonated graphene is 30:1;

[0079] Under the conditions that the rotating speed of the atomizing disc is 1800rpm and the drying temperature is 200°C, the grinding product with a solid content of 40wt% is spray-granulated to obtain a graphite negative electrode precursor;

[0080] The graphite negative electrode precursor was sintered in a nitrogen atmosphere furnace at 500° C. for 48 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com