Active material for batteries, non-aqueous electrolyte battery, and battery pack

A non-aqueous electrolyte, active material technology, applied in non-aqueous electrolyte batteries, active material electrodes, battery electrodes, etc., can solve the problems of capacity reduction and less equivalent sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0031] According to the first embodiment, an active material for a battery is provided. This battery active material contains a composite oxide represented by the following general formula: General formula Li x (Nb 1-y Ta y ) 2+0.5z Ti 1-z M 0.5z O 7 (0≤x≤5, 0≤y≤1, 0<z≤1). In the formula, M is at least one metal element selected from the group consisting of Sc, Y, V, Cr, Fe, Co, Mn, Al, and Ga.

[0032] General formula Li x (Nb 1-y Ta y ) 2+0.5z Ti 1-z M 0.5z O 7 The represented composite oxide may have a monoclinic crystal structure.

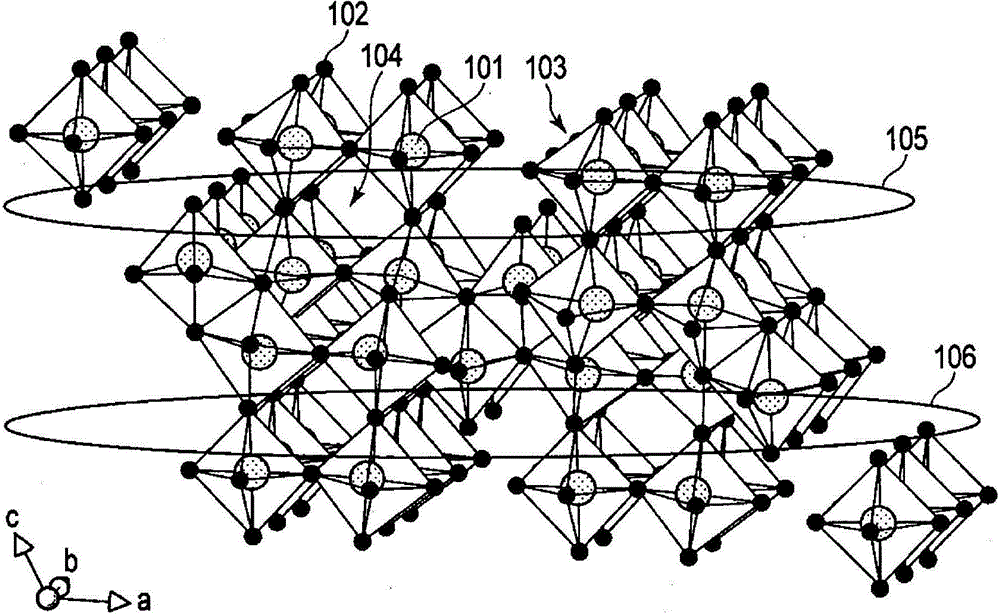

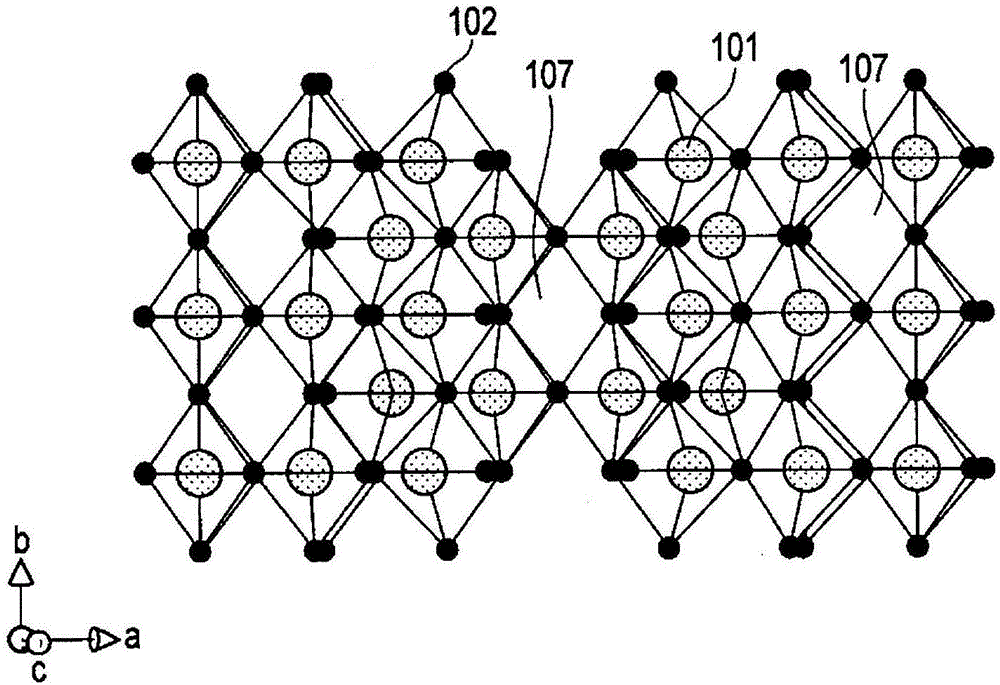

[0033] as the general formula Li x (Nb 1-y Ta y ) 2+0.5z Ti 1-z M 0.5z O 7 An example of a complex oxide represented by (0≤x≤5, 0≤y≤1, 02 (Nb 0.05 Ti 0.9 Fe 0.05 )O 7 A schematic diagram of the crystal structure is shown in figure 1 and 2 middle.

[0034] like figure 1 As shown, in the monoclinic complex oxide Nb 2 (Nb 0.05 Ti 0.9 Fe 0.05 )O 7 In the crystal structure of , metal ions 101 and oxide ions 102 cons...

no. 2 Embodiment approach

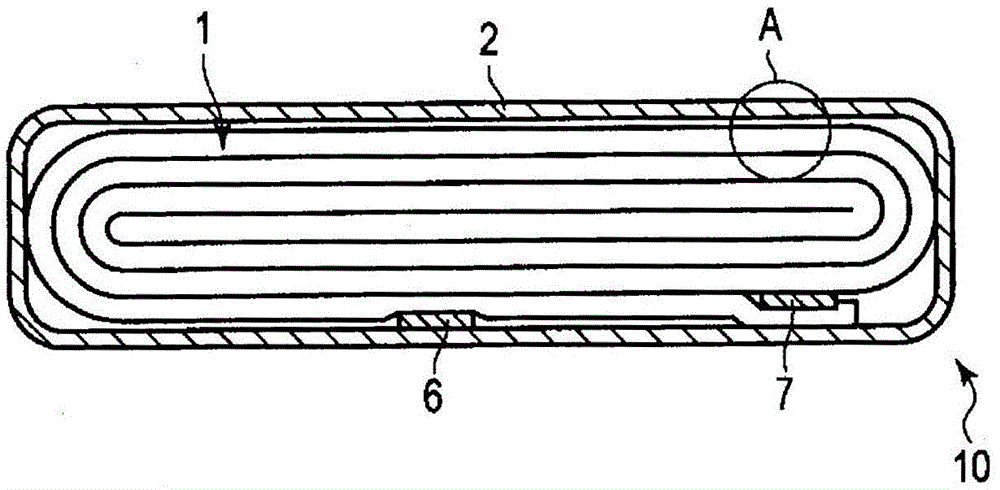

[0089] According to the second embodiment, a non-aqueous electrolyte battery including the battery active material of the first embodiment can be provided. This non-aqueous electrolyte battery includes a negative electrode, a positive electrode, and a non-aqueous electrolyte. The battery active material of the first embodiment can be used for a negative electrode or a positive electrode, or for both the negative electrode and the positive electrode.

[0090] The non-aqueous electrolyte battery of the second embodiment may further include a separator disposed between the positive electrode and the negative electrode. The positive electrode, the negative electrode and the separator can constitute an electrode group. The nonaqueous electrolyte can be held in the electrode group.

[0091] In addition, the non-aqueous electrolyte battery of the second embodiment may further include an outer packaging member for accommodating the electrode group and the non-aqueous electrolyte.

...

no. 3 Embodiment approach

[0151] According to a third embodiment, a battery pack is provided. The battery pack includes the non-aqueous electrolyte battery of the second embodiment.

[0152] The battery pack of the third embodiment may include a plurality of non-aqueous electrolyte batteries. A plurality of nonaqueous electrolyte batteries may be electrically connected in series, or may be electrically connected in parallel. Alternatively, a plurality of non-aqueous electrolyte batteries may be connected in a combination of series and parallel.

[0153] Below, refer to Figure 7 and Figure 8 An example of the battery pack of the third embodiment will be described.

[0154] Figure 7 It is an exploded perspective view of a battery pack according to an example of the third embodiment. Figure 8 is to indicate Figure 7 Block diagram of the circuit of the battery pack.

[0155] Figure 7 and Figure 8 The illustrated battery pack 20 includes a plurality of cells 21 . The single cell 21 is for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com