Active material for battery, non-aqueous electrolyte battery and battery pack

A non-aqueous electrolyte and active material technology, applied in non-aqueous electrolyte batteries, active material electrodes, battery electrodes, etc., can solve the problems of less equivalent sites and capacity reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0031] According to the first embodiment, an active material for a battery is provided. The battery active material contains a composite oxide represented by the general formula: Li x (Nb 1-y Ta y ) 2+0.5z Ti 1-z m 0.5z o 7 (0≤x≤5, 0≤y≤1, 0<z≤1). In the formula, M is at least one metal element selected from the group consisting of Sc, Y, V, Cr, Fe, Co, Mn, Al and Ga.

[0032] Formula Li x (Nb 1-y Ta y ) 2+0.5z Ti 1-z m 0.5z o 7 The indicated composite oxide may have a monoclinic crystal structure.

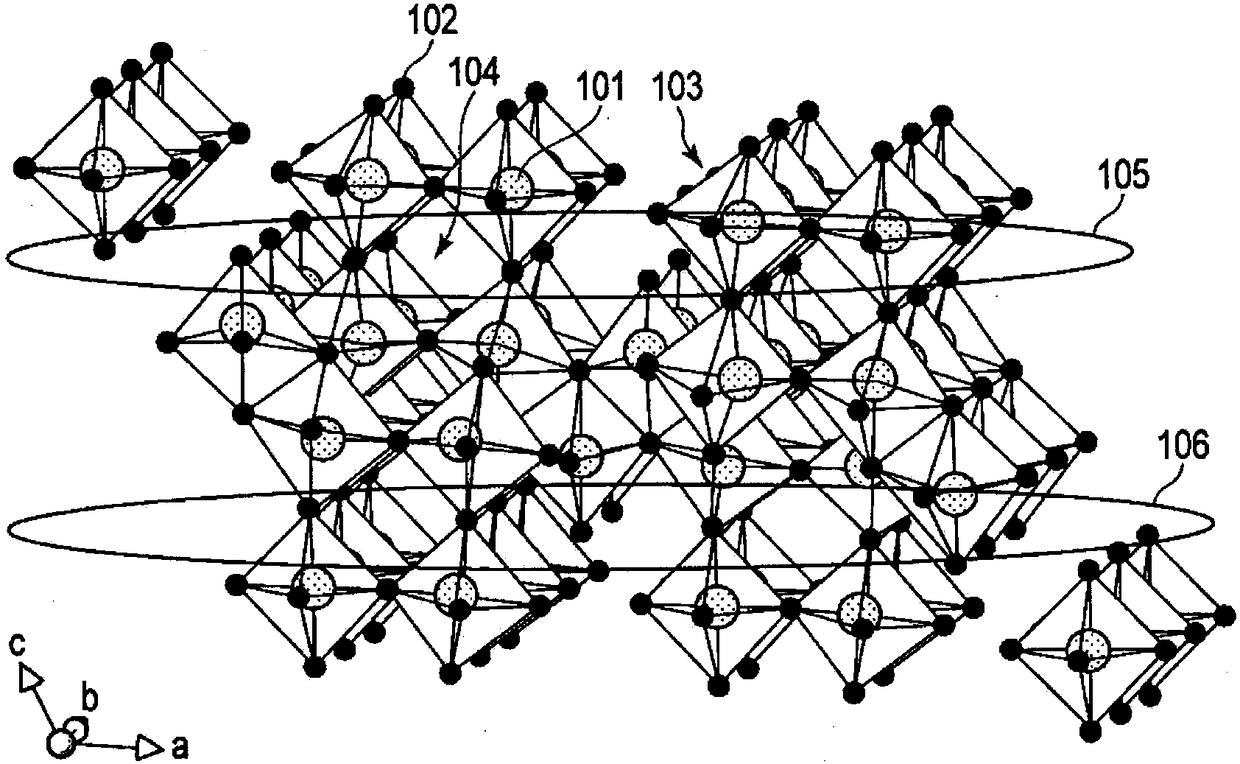

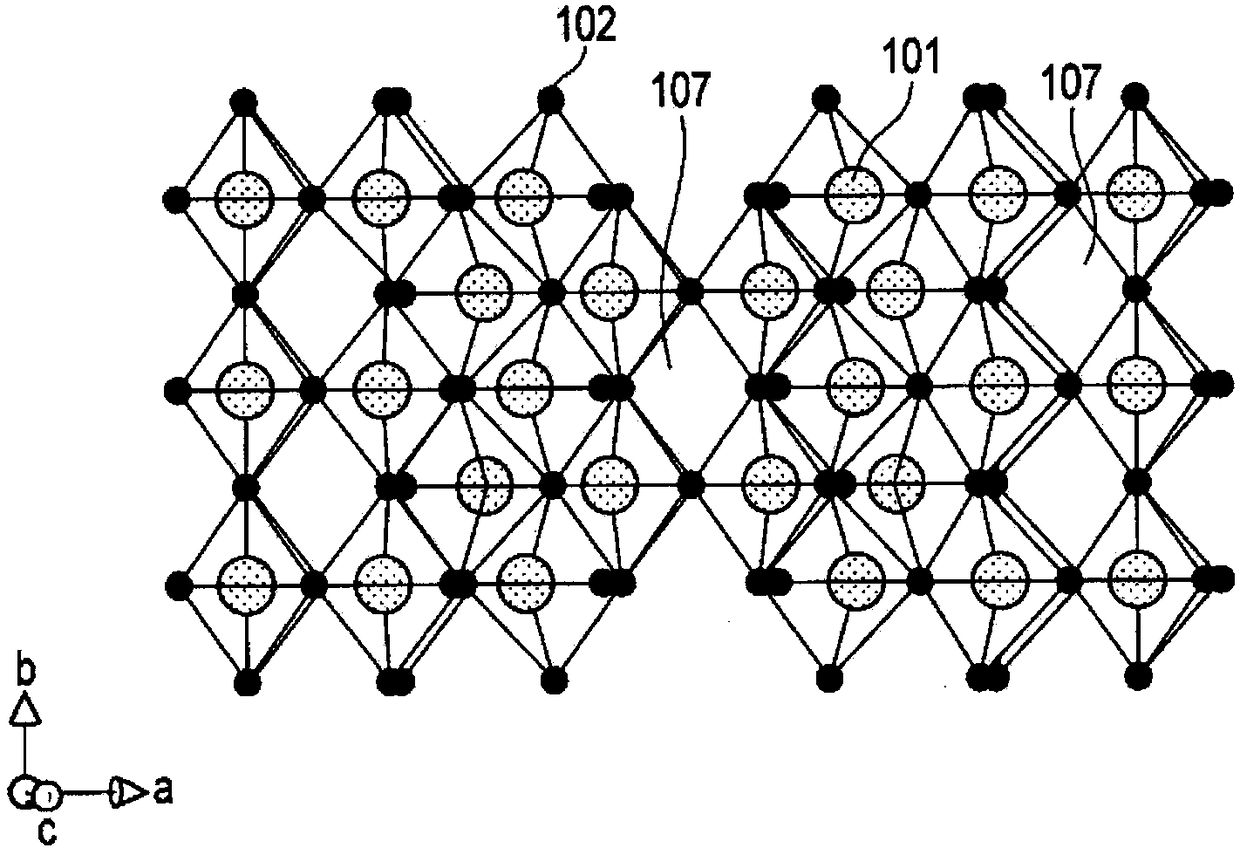

[0033] As the general formula Li x (Nb 1-y Ta y ) 2+0.5z Ti 1-z m 0.5z o 7 An example of the composite oxide represented by (0≤x≤5, 0≤y≤1, 02 (Nb 0.05 Ti 0.9 Fe 0.05 )O 7 A schematic diagram of the crystal structure is shown in figure 1 and 2 middle.

[0034] Such as figure 1 As shown, in the monoclinic composite oxide Nb 2 (Nb 0.05 Ti 0.9 Fe 0.05 )O 7 In the crystal structure of , metal ions 101 and oxide ions 102 constitute a skeleton structure p...

no. 2 Embodiment approach

[0089] According to the second embodiment, a non-aqueous electrolyte battery including the active material for a battery of the first embodiment can be provided. The nonaqueous electrolyte battery includes a negative electrode, a positive electrode, and a nonaqueous electrolyte. The battery active material according to the first embodiment can be used for a negative electrode, a positive electrode, or both of the negative electrode and the positive electrode.

[0090] The non-aqueous electrolyte battery of the second embodiment may further include a separator disposed between the positive electrode and the negative electrode. The positive electrode, the negative electrode, and the separator can constitute an electrode group. A non-aqueous electrolyte may be held in the electrode group.

[0091] In addition, the non-aqueous electrolyte battery of the second embodiment may further include an exterior member for accommodating the electrode group and the non-aqueous electrolyte....

no. 3 Embodiment approach

[0151] According to a third embodiment, a battery pack is provided. This battery pack includes the nonaqueous electrolyte battery of the second embodiment.

[0152] The battery pack of the third embodiment may include a plurality of non-aqueous electrolyte batteries. A plurality of nonaqueous electrolyte batteries may be electrically connected in series, or may be electrically connected in parallel. Alternatively, a plurality of non-aqueous electrolyte batteries may be connected in series and in parallel in combination.

[0153] Below, refer to Figure 7 and Figure 8 An example of the battery pack of the third embodiment will be described.

[0154] Figure 7 It is an exploded perspective view of a battery pack as an example of the third embodiment. Figure 8 yes means Figure 7 A block diagram of the battery pack circuit.

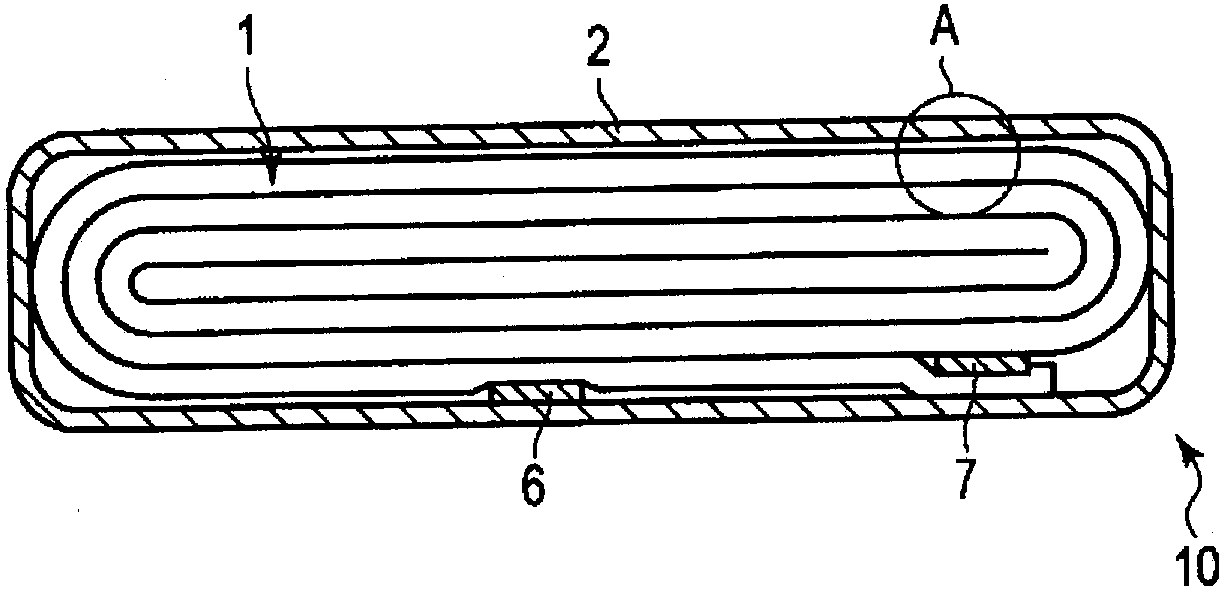

[0155] Figure 7 and Figure 8 The illustrated battery pack 20 includes a plurality of single cells 21 . single cell 21 for reference image 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com