TiO2-coated graphite composite particle for lithium ion battery, and preparation method and application thereof

A technology of composite particles and graphite, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve problems such as high cost and safety, and achieve the effect of improving safety, good safety, and avoiding lithium precipitation on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

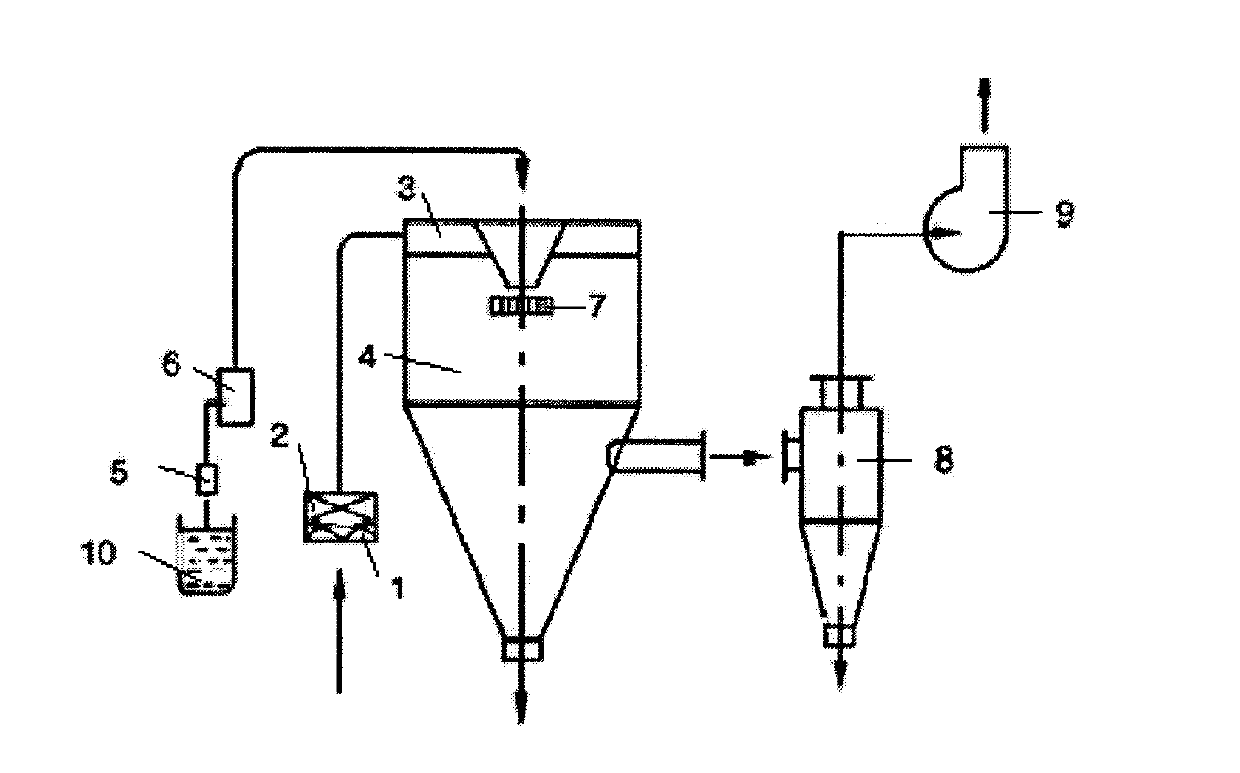

[0035] TiO 2Preparation of sol: Mix tetra-n-butyl titanate, water and diethanolamine at a molar ratio of 8:1:26, stir in a vacuum mixer for 2.5 hours to obtain the final mixture, and then add a water-containing ethanol solution with a water concentration of 15mol / L , the volume of the added aqueous ethanol solution is 1 / 10 of the volume of the final mixed solution, fully stirred until the solution is clear to obtain 0.45mol / L TiO 2 Sol.

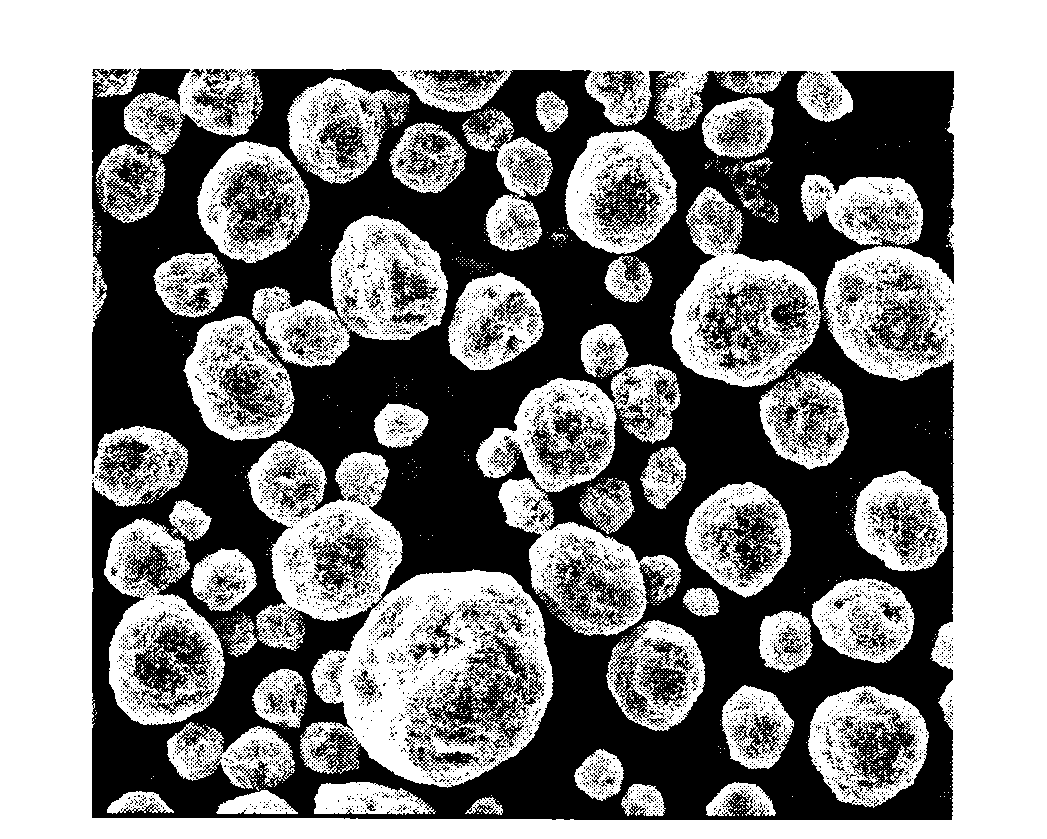

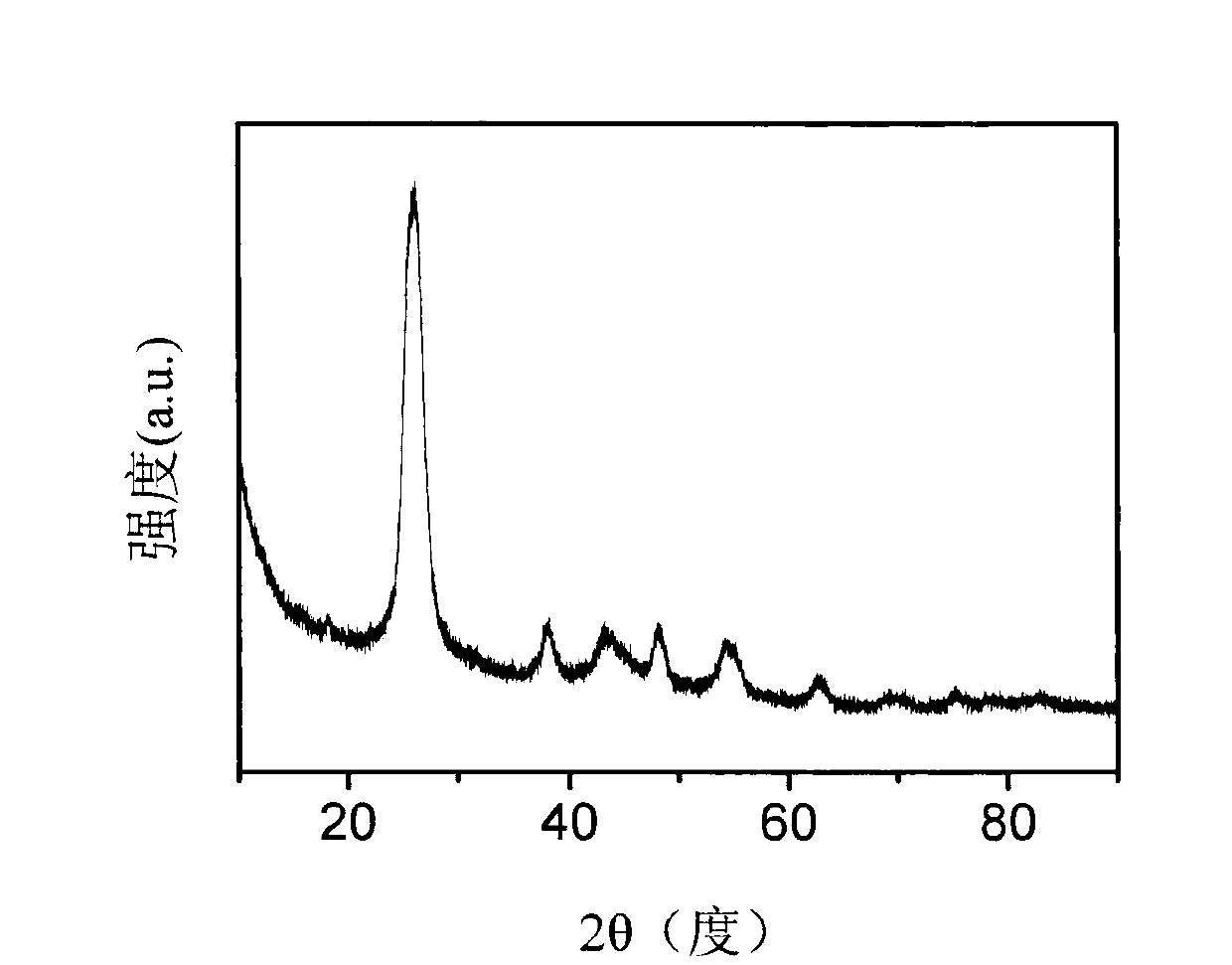

[0036] Will D 50 Add the above TiO to 10 μm spherical graphite (Qingdao Hengsheng Graphite Co., Ltd., HSG-10) 2 In the sol, the molar ratio of graphite to tetra-n-butyl titanate is calculated at 80:1, stirred for 1 h, then the obtained mixed slurry is granulated into balls by a spray granulator and dried, and the outlet of the cyclone separator 8 is collected. Material, get the cyclone material that particle size median value is 5-15 μ m. Under the protection of Ar atmosphere, the temperature was raised to 700°C at a rate of 2°C / min at ro...

Embodiment 2

[0042] TiO 2 Preparation of sol: Mix tetra-n-butyl titanate, water, and triethanolamine at a molar ratio of 8:1:18, stir in a vacuum mixer for 2.5 hours to obtain the final mixture, and then add a water-containing ethanol solution with a water concentration of 15mol / L , the volume of the added aqueous ethanol solution is 1 / 10 of the volume of the final mixed solution, fully stirred until the solution is clear to obtain 0.81mol / L TiO 2 Sol.

[0043] Will D 50 Add the above TiO to 10 μm spherical graphite (Qingdao Hengsheng Graphite Co., Ltd., HSG-10) 2 In the sol, the molar ratio of graphite to tetra-n-butyl titanate is calculated at 80:1, stirred for 1 h, then the obtained mixed slurry is granulated into balls by a spray granulator and dried, and the outlet of the cyclone separator 8 is collected. The material, under the protection of Ar atmosphere, was heated at room temperature to 800°C at a rate of 2°C / min, and calcined at 800°C for 4 hours to obtain TiO 2 Coated graphi...

Embodiment 3

[0046] TiO 2 Preparation of sol: Mix tetra-n-butyl titanate, water and monoethanolamine at a molar ratio of 8:1:32, stir in a vacuum mixer for 2.5 hours to obtain the final mixture, and then add a water-containing ethanol solution with a water concentration of 15mol / L , the volume of the added aqueous ethanol solution is 1 / 10 of the volume of the final mixed solution, fully stirred until the solution is clear to obtain 0.39mol / L TiO 2 Sol.

[0047] Will D 50 Add the above TiO to 10 μm spherical graphite (Qingdao Hengsheng Graphite Co., Ltd., HSG-10) 2 In the sol, the molar ratio of graphite to tetra-n-butyl titanate is calculated at 90:1, stirred for 1 h, then the obtained mixed slurry is granulated into balls by a spray granulator and dried, and the outlet of the cyclone separator 8 is collected. The material, under the protection of Ar atmosphere, was heated at room temperature to 800°C at a rate of 2°C / min, and calcined at 800°C for 4 hours to obtain TiO 2 Coated graphi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com