Micro-mesoporous polytriphenylamine derivative applied to lithium battery, as well as preparation method thereof

A polytriphenylamine and micro-mesoporous technology, applied in battery electrodes, secondary batteries, electrochemical generators, etc., to achieve high charge-discharge specific capacity, superior charge-discharge performance, and excellent fast charge-discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

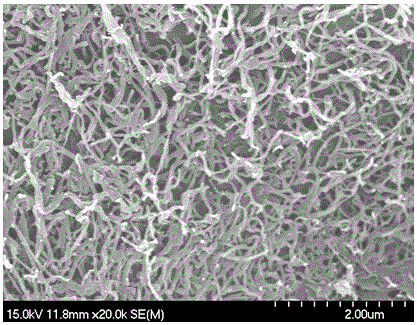

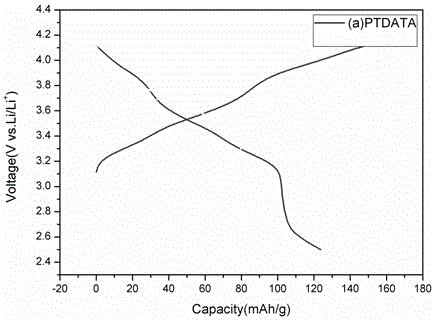

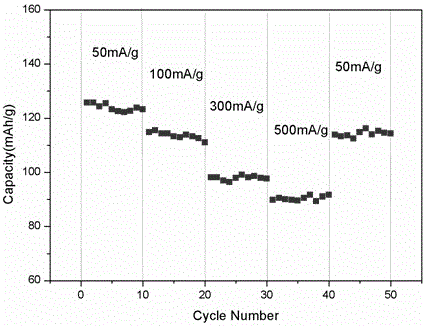

Image

Examples

Embodiment 1

[0033] Preparation of polymer (PTDATA)

[0034] (1) Synthesis of 4,4′,4"-tris(N,N-diphenylamino)triphenylamine (TDATA)

[0035] In a dry 250 mL three-necked flask, add 2.492 g (4 mmol) iodotriphenylamine, 2.708 g (16 mmol) diphenylamine, 0.337 g palladium acetate, 2.244 g potassium tert-butoxide, then add 100 mL o-xylene, and stir dissolved, and added 4.8 mL of tributylphosphine to the reaction system with a syringe under nitrogen protection, and stirred and refluxed at 120°C for 12 hours. After the reaction was completed, the solution was filtered while it was hot, added with chloroform and distilled water for repeated washing several times, and the obtained extract was evaporated to dryness with a rotary evaporator to obtain a light yellow solid. The solid was then dissolved in chloroform, and decolorized with a short silica gel column to obtain a light yellow solution, which was spin-dried to obtain a light yellow crude product. The solid was recrystallized from tetrahydr...

Embodiment 2

[0039] Electrode preparation and battery assembly

[0040] (1) Preparation of electrodes. Electrode sheets were prepared on the surface of aluminum foil by coating method. Dissolve the active material polymer powder: conductive agent acetylene black: binder PVDF = mass ratio 4:5:1 in the solvent N-methylpyrrolidone (NMP) to form a viscous liquid. Then the liquid was coated on a clean aluminum foil with a 90 nm doctor blade, and then dried in vacuum at 60 °C until the quality of the film remained unchanged.

[0041] (2) Assembly of the battery. In this paper, the CR2032 battery device system is mainly used to test the electrochemical performance and charge and discharge performance of the battery. Lithium is used as the negative electrode and reference electrode, and the electrolyte is 1 M LiPF 6 EC:DMC =1:1 (v / v) solution, the diaphragm is a polypropylene microporous membrane (Celgard 2300) used in industrialization, the electrode prepared before is the positive electrode,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com