Manganous fluoride-carbon composite material as well as preparation method and application thereof

A technology of carbon composite materials and manganous fluoride, applied in electrochemical generators, active material electrodes, electrical components, etc., can solve problems such as shortening the service life of lithium-ion batteries, capacity decay of lithium-ion batteries, and large volume expansion effects , achieve broad market application prospects, mild reaction conditions and easy control, and increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] A kind of manganese fluoride-carbon composite material, its preparation method comprises the following steps:

[0082] Step 1): Dissolve 0.502g manganese nitrate tetrahydrate in N,N-dimethylformamide (35mL), stir continuously, then add 0.3623g of 1,4-phthalic acid (H 2 BDC) and 1.5g polyvinylpyrrolidone, stirred and dissolved, then transferred to the reaction kettle, reacted at 110°C for 24h, then filtered to separate the solid product and rinsed it with N,N-dimethylformamide several times to obtain a white precipitate , and then put the white precipitate into an air-drying oven, and dry it at 60° C. for 8 h to obtain a layered Mn-BDC precursor (referred to as Mn-BDC).

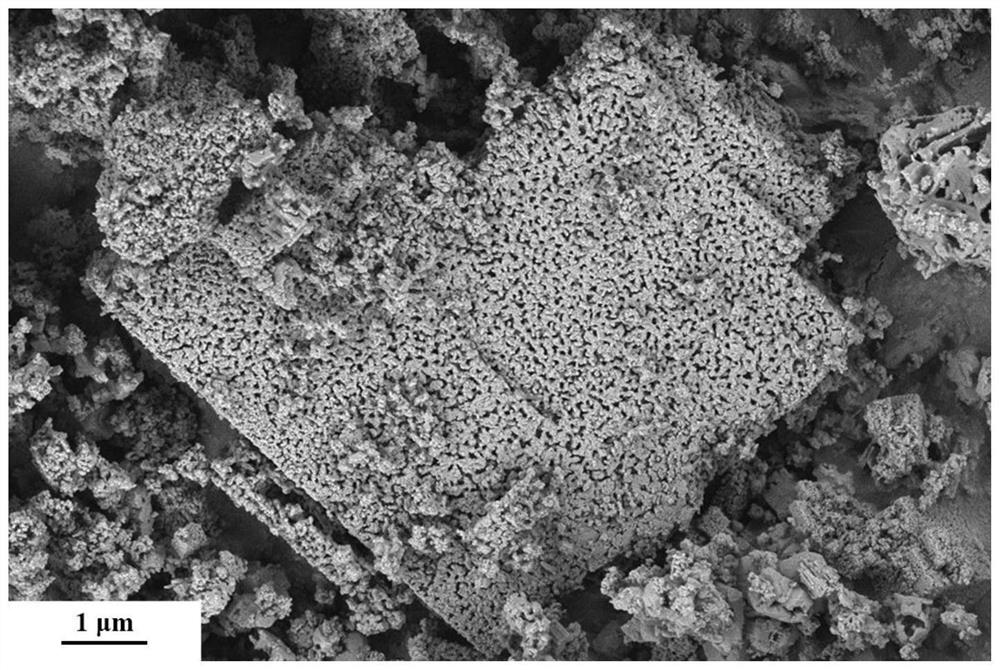

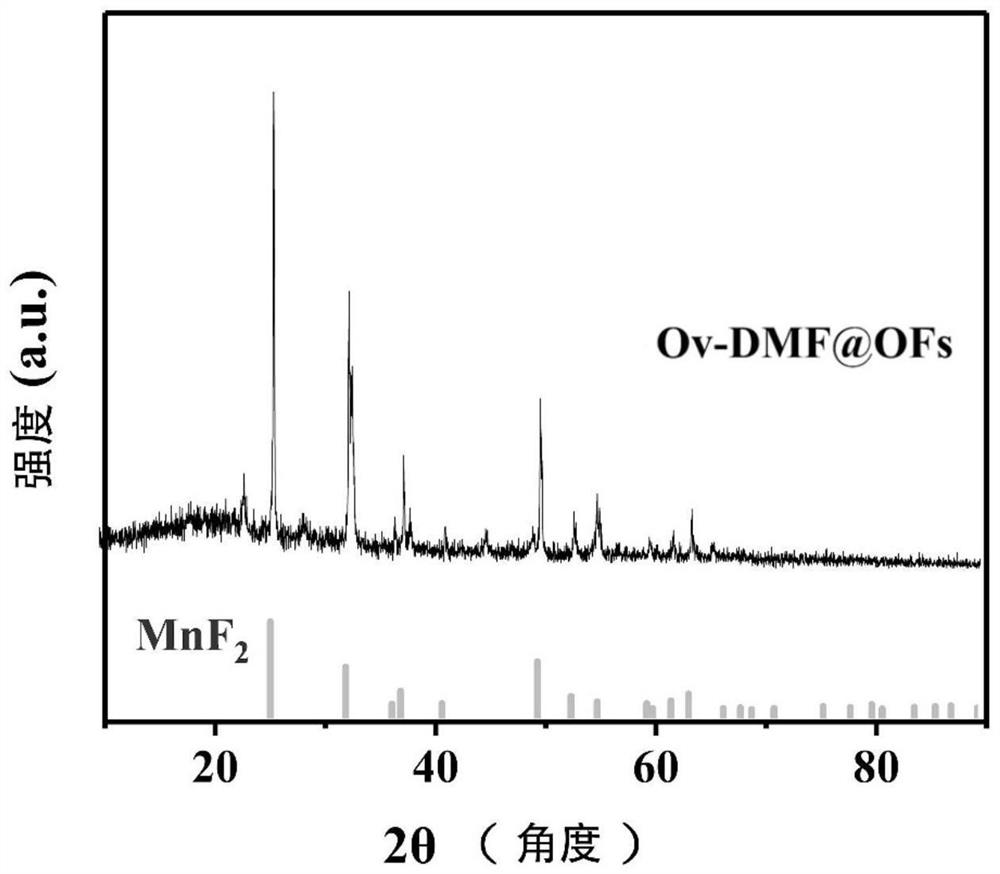

[0083] Step 2): Mn-BDC and ammonium fluoride were mixed according to the mass ratio of 1:15, placed in an oxygen atmosphere, and calcined at 600°C for 3 hours to obtain a manganous fluoride-carbon composite material (referred to as Ov-DMF@OFs).

[0084] Characterization test

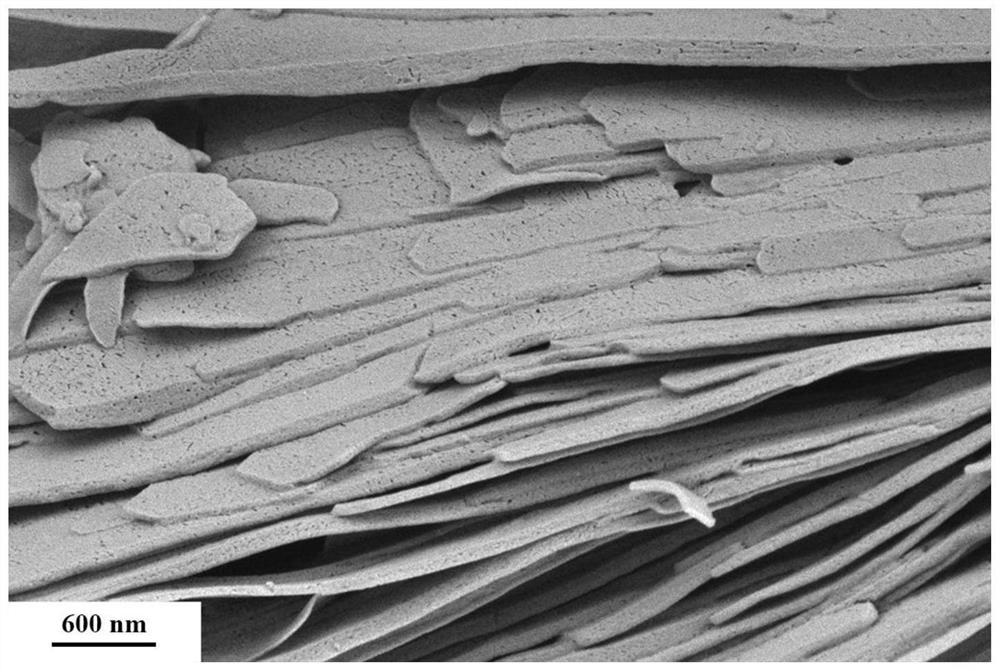

[0085] (1) SEM character...

Embodiment 2

[0133] Step 1): Dissolve 0.502g manganese nitrate tetrahydrate in N,N-dimethylformamide (35mL), stir continuously, then add 0.3623g of 1,4-phthalic acid (H 2 BDC) was stirred until dissolved, then transferred to the reaction kettle, reacted at 110°C for 24 hours, and then filtered to separate the solid product and rinsed with N,N-dimethylformamide several times to obtain a white precipitate, and then put the white precipitate Put it into an air-drying oven and dry at 60° C. for 8 hours to obtain an amorphous Mn-BDC precursor.

[0134] Step 2): Put 0.1 g of Mn-BDC and 10 mL of hydrofluoric acid into a 110° C. reactor for 12 hours to react to obtain a manganous fluoride-carbon composite material (referred to as MFC-VS).

[0135] After testing (the test method is the same as in Example 1), the composition of MFC-VS and Ov-DMF@OFs is highly similar, and the negative electrode of the lithium-ion battery assembled by it also has the characteristics of good cycle stability and long s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com