Preparation method of gel electrolyte and application thereof in field of lithium ion batteries

A gel electrolyte, ionic liquid technology, applied in the field of lithium-ion batteries and chemical power sources, can solve the problems of poor temperature tolerance, low safety performance, flammable and explosive safety performance, etc., and achieve high electrical conductivity, charge-discharge specific capacity, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

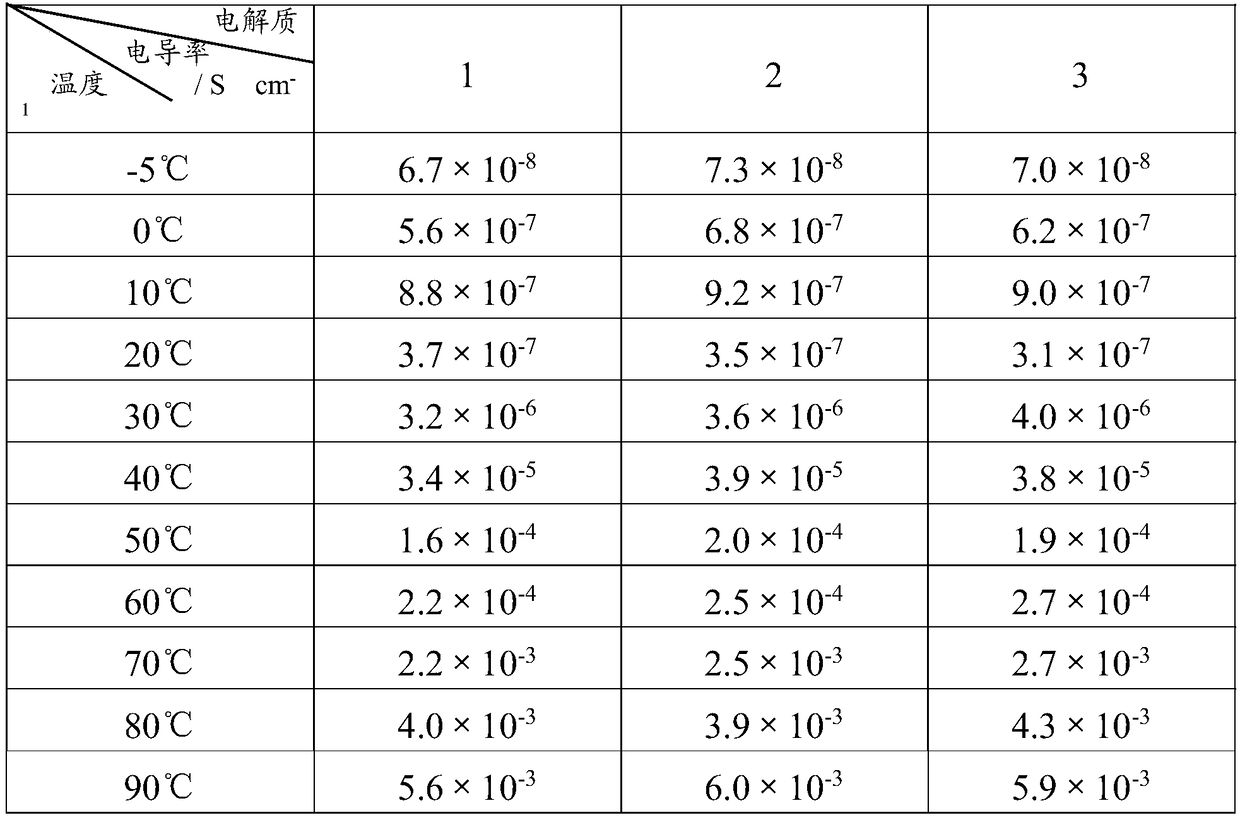

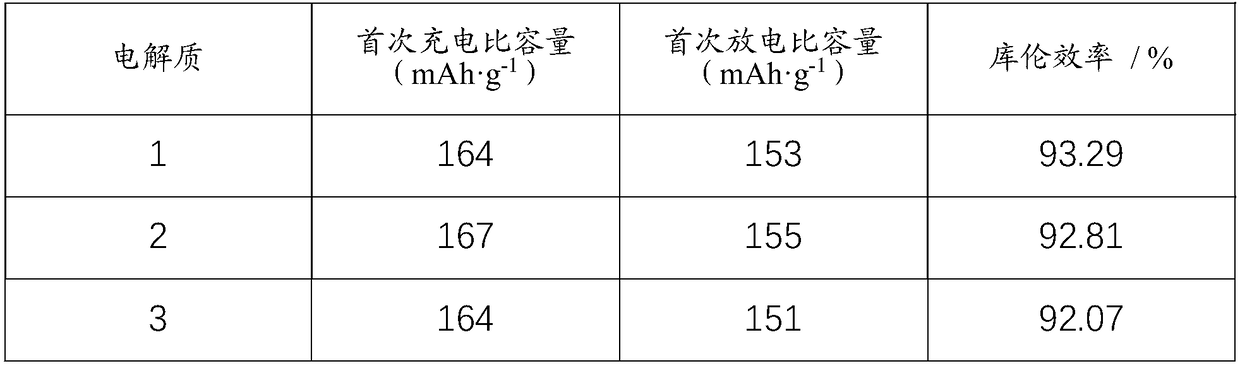

[0025] This example is a specific example of preparing the gel electrolyte 1 using the above composition.

[0026] 0.5g of ionic liquid polymer-polypyrrolidine bistrifluoromethanesulfonimide and 0.02g of filler 1 were dissolved in 8mL of solvent 1, coated on a glass plate, and dried in vacuum after the solvent evaporated to obtain a translucent porous The film, after cutting it into discs with a diameter of 16 mm, is the product A1. Among them, the inorganic filler 1 is SBA-15, the solvent 1 is acetone; the temperature of vacuum drying is 95°C.

[0027] In the glove box, dissolve 0.2g LiTFSI in the ionic liquid monomer—N-methyl-N-butylpyrrolidine bistrifluoromethanesulfonimide salt, and mix well to obtain the product B1. Wherein, the preparation method of the ionic liquid monomer is as follows: 4 g of 1-methylpyrrolidine and 6 g of bromobutane are dissolved in acetonitrile, heated in an oil bath, and the reaction does not exceed 24 hours. After the reaction, the acetonitrile...

Embodiment 2

[0030] This example is a specific example of preparing the gel electrolyte 2 using the above composition.

[0031] 0.5g of ionic liquid polymer-polypyrrolidine bistrifluoromethanesulfonimide and 0.025g of filler 2 were dissolved in 8mL of solvent 2, coated on a glass plate, and dried in vacuum after the solvent evaporated to obtain a translucent porous The film, after cutting it into discs with a diameter of 16 mm, is the product A2. Among them, the inorganic filler 2 is LiAlO 2 , solvent 2 is N,N-dimethylformamide; the temperature of vacuum drying is 100°C.

[0032] In the glove box, dissolve 0.19g LiFSI in the ionic liquid monomer—N-methyl-N-butylpyrrolidine bistrifluoromethanesulfonimide salt, and mix well to obtain the product B2. Among them, the preparation method of the ionic liquid monomer is as follows: 5 g of 1-methylpyrrolidine and 8 g of bromobutane are dissolved in acetonitrile, heated in an oil bath, and the reaction does not exceed 24 hours. After the reaction...

Embodiment 3

[0035] This example is a specific example of preparing the gel electrolyte 3 using the above composition.

[0036] 0.5g of ionic liquid polymer-polypyrrolidine bistrifluoromethanesulfonimide and 0.025g of filler 3 were dissolved in 8mL of solvent 3, coated on a glass plate, and dried in vacuum after the solvent evaporated to obtain a translucent porous The film, after cutting it into discs with a diameter of 16 mm, is product A3. Among them, the inorganic filler 3 is Al 2 o 3 , solvent 3 is methanol; the temperature of vacuum drying is 120°C.

[0037] In the glove box, dissolve 0.1g LiFSI in the ionic liquid monomer—N-methyl-N-butylpyrrolidine bistrifluoromethanesulfonimide salt, and mix well to obtain the product B3. Among them, the preparation method of the ionic liquid monomer is as follows: 8 g of 1-methylpyrrolidine and 15 g of bromobutane are dissolved in acetonitrile, heated in an oil bath, and the reaction does not exceed 24 hours. After the reaction, the acetonitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com