Calcium potassium niobate composite salt negative electrode material for potassium ion battery and preparation process of calcium potassium niobate composite salt negative electrode material

A negative electrode material, potassium ion technology, applied in the direction of battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of low charge and discharge Coulomb efficiency, no stable charge and discharge platform, and high potential of charge and discharge platform, and achieve easy control of reaction conditions , excellent cycle stability, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

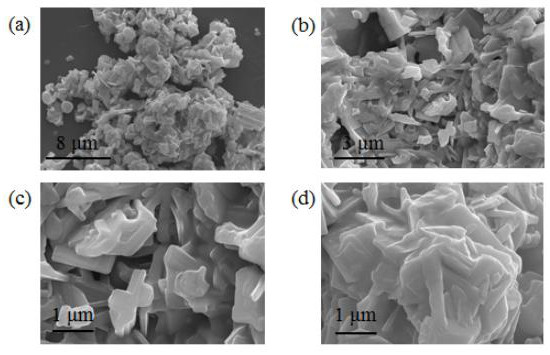

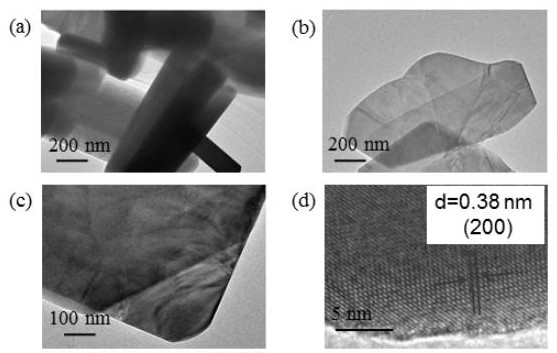

[0052] This example shows a KCa 2 Nb 3 o 10 Synthesis method of negative electrode material.

[0053] (1) Accurately weigh 6.7332 g potassium hydroxide (KOH), and pour it into (25 ml) polytetrafluoroethylene hydrothermal kettle;

[0054] (2) Accurately measure 15 ml of deionized water with a graduated cylinder, and slowly drop the deionized water in the graduated cylinder into a hydrothermal kettle filled with potassium hydroxide with a dropper;

[0055] (3) Accurately weigh 299.8 mg niobium pentoxide (Nb 2 o 5 ), 111.4 mg calcium hydroxide Ca(OH) 2 , pour it into the above-mentioned hydrothermal kettle, and magnetically stir for 0.5 h;

[0056] (4) Hydrothermal reaction was carried out at 200 °C, and the reaction time was 72 h;

[0057] (5) Then cool to room temperature, turn on the hydrothermal kettle to remove the supernatant, wash with deionized water, centrifuge in a centrifuge at a speed of 4000rpm, place the centrifuged product in an ordinary oven, and dry at 80°...

Embodiment 2

[0065] This example shows a transition metal compound KCa 2 Nb 3 o 10 Potassium-ion battery with negative electrode.

[0066] The composition of the negative electrode material of the potassium ion battery (taking the mass fraction of the negative electrode material as 100%): making the negative electrode active material: conductive acetylene black: CMC binder = 7: 2: 1 (wt%: wt%: wt%), then Place the container in a vacuum stirrer and stir for 1 h, and apply the stirred slurry on the surface of the aluminum foil, so that the active material load is maintained at about 1-2 mg / cm 2 . After coating, the aluminum foil was quickly transferred to a vacuum oven at 80 °C for 12 h. Afterwards, the prepared electrode sheets were cut into small discs with a diameter of 10 mm using a punching machine, and weighed quickly to prevent the electrode sheets from absorbing moisture in the air and resulting in large weighing errors. The weighed electrode sheet was again placed in a vacuum o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com