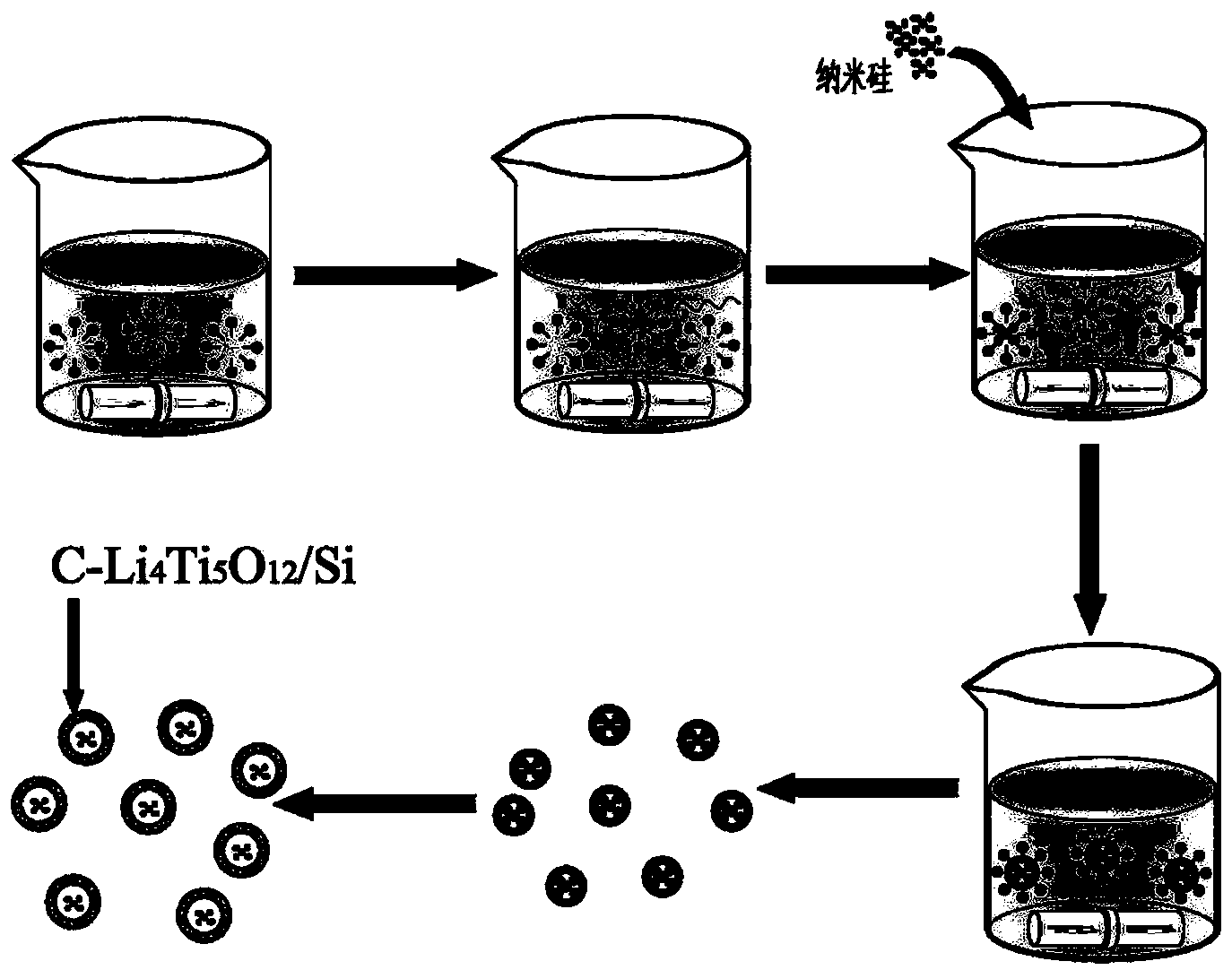

Preparation method of carbon-lithium titanate double-layer coated silicon negative electrode material

A double-layer coating, lithium titanate technology, used in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of hindering the insertion and extraction of lithium ions, affecting the performance of batteries, and low electrical conductivity. The effect of uniformity, large specific capacity and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The soluble compound compounds of Li and Ti were mixed according to the molar ratio of Li:Ti=0.84:1, and 25.52g of tetra-n-butyl titanate (analytical pure), 2.33g of lithium carbonate (analytical pure), 20g were weighed Ethylenediaminetetraacetic acid and 30 g of citric acid were added to 300 ml of absolute ethanol, and stirred by a magnetic heating stirrer to form a sol; then 0.2 g of nano silicon powder was added and heated and stirred at 80°C until the silicon source was fully dispersed. Glue; dried in a blast oven at 240℃ to obtain a black and fluffy lithium titanate coated silicon precursor; then put the precursor into a high-energy ball mill for ball milling for 1-10 hours, where the mass ratio of the ball to the material is 2: 1. Obtain a silicon precursor coated with fine particles of lithium titanate; finally, put the fine particles of the precursor into a tube furnace, pass it through Ar gas, and calcine at 750°C for 5 hours to obtain a finished carbon and lithi...

Embodiment 2

[0023] The soluble compound compounds of Li and Ti are mixed according to the molar ratio of Li:Ti=0.84:1, and 21.31 g of tetraisopropyl titanate (analytical purity), 6.43g of lithium acetate (analytical purity), 20g are weighed Ethylenediaminetetraacetic acid and 40g of citric acid were added to 300ml of absolute ethanol, and stirred by a magnetic heating stirrer to form a sol; then 0.2g of mesoporous silicon nanoparticles were added and heated and stirred at 80°C until the silicon source was fully dispersed. Gel; dried in a blast oven at 240℃ to obtain a black and fluffy lithium titanate coated silicon precursor; then put the precursor into a high-energy ball mill for ball milling for 1-10 hours, where the mass ratio of the ball to the material is 2 :1. Obtain a silicon precursor coated with fine particles of lithium titanate; finally put the fine particles of the precursor into a tube furnace, pass 95%Ar+5%H 2 , Calcined at 750°C for 5 hours to obtain the finished carbon and ...

Embodiment 3

[0025] The soluble compound compounds of Li and Ti were mixed according to the molar ratio of Li:Ti=0.88:1, and 25.52 g of tetra-n-butyl titanate (analytical purity), 4.55g of lithium nitrate (analytical purity), 20g were weighed Ethylenediaminetetraacetic acid and 60g citric acid were added to 300ml of absolute ethanol, and stirred by a magnetic heating stirrer to form a sol; then 0.6g of nano-silica powder was added and heated and stirred at 80°C until a gel with fully dispersed silicon source was obtained ; Dry in a blast oven at 240℃ to obtain a black and fluffy lithium titanate coated silicon precursor; then put the lithium titanate precursor into a high-energy ball mill for ball milling for 1-10 h, where the mass ratio of the ball to the material The ratio is 2:1 to obtain a silicon precursor coated with fine particles of lithium titanate; finally, the fine particles of the precursor are put into a tube furnace, and the precursor is vented with Ar gas and calcined at 750°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com