Preparation method of lithium battery high-voltage modified cathode material

A negative electrode material, high voltage technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low conductivity of lithium metal oxide, poor rate performance of lithium titanate, low energy density, etc., and achieve good fast charging Discharge performance, easy industrial production, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

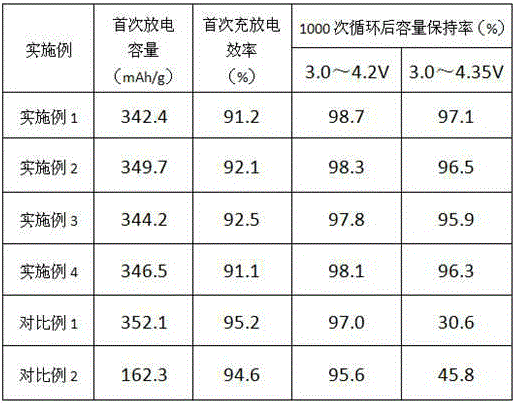

Examples

Embodiment 1

[0015] Weigh the lithium titanate material accounting for 5% of the total weight of graphite and lithium titanate material, and stir it with graphite to make it fully mixed. The stirring and mixing time is 3 hours, so that the lithium titanate material is evenly wrapped on the graphite surface; then at 1500 ° C Heat treatment for 1 hour, so that the lithium titanate material is melted and wrapped on the surface of the graphite particles, thereby forming a stable lithium titanate coating layer; finally, carbon nanotubes are added in a proportion of 2% of the total weight of the negative electrode material, and the carbon nanotubes coated with lithium titanate The graphite material was ball milled for 8 hours to obtain a three-layer negative electrode material of graphite / lithium titanate / conductive agent.

Embodiment 2

[0017] The lithium titanate material accounts for 1% of the total weight of the graphite and lithium titanate materials, and is stirred with the graphite to make it fully mixed. The stirring and mixing time is 5 hours, so that the lithium titanate material is evenly wrapped on the surface of the graphite; then at 1800 ° C Heat treatment for 1 hour, so that the lithium titanate material is melted and wrapped on the surface of the graphite particles, thereby forming a stable lithium titanate coating layer; finally, the vapor phase growth carbon fiber is added in a proportion of 1% of the total weight of the negative electrode material, and the lithium titanate coated The graphite material was ball milled for 24 hours to obtain a three-layer negative electrode material of graphite / lithium titanate / conductive agent.

Embodiment 3

[0019] Weigh the lithium titanate material accounting for 10% of the total weight of the graphite and lithium titanate materials, and stir it with the graphite to make it fully mixed. The stirring and mixing time is 5 hours, so that the lithium titanate material is evenly wrapped on the graphite surface; then at 1600 ° C Heat treatment for 1 hour, so that the lithium titanate material is melted and wrapped on the surface of the graphite particles, thereby forming a stable lithium titanate coating layer; finally, carbon nanotubes are added in a proportion of 5% of the total weight of the negative electrode material, and then coated with lithium titanate The graphite material was ball milled for 20 hours to obtain a three-layer negative electrode material of graphite / lithium titanate / conductive agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com