Linear hierarchy lithium titanate material, as well as preparation and application thereof

A technology to structure lithium titanate, hierarchical structure, applied in the direction of titanate, nanotechnology for materials and surface science, structural parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

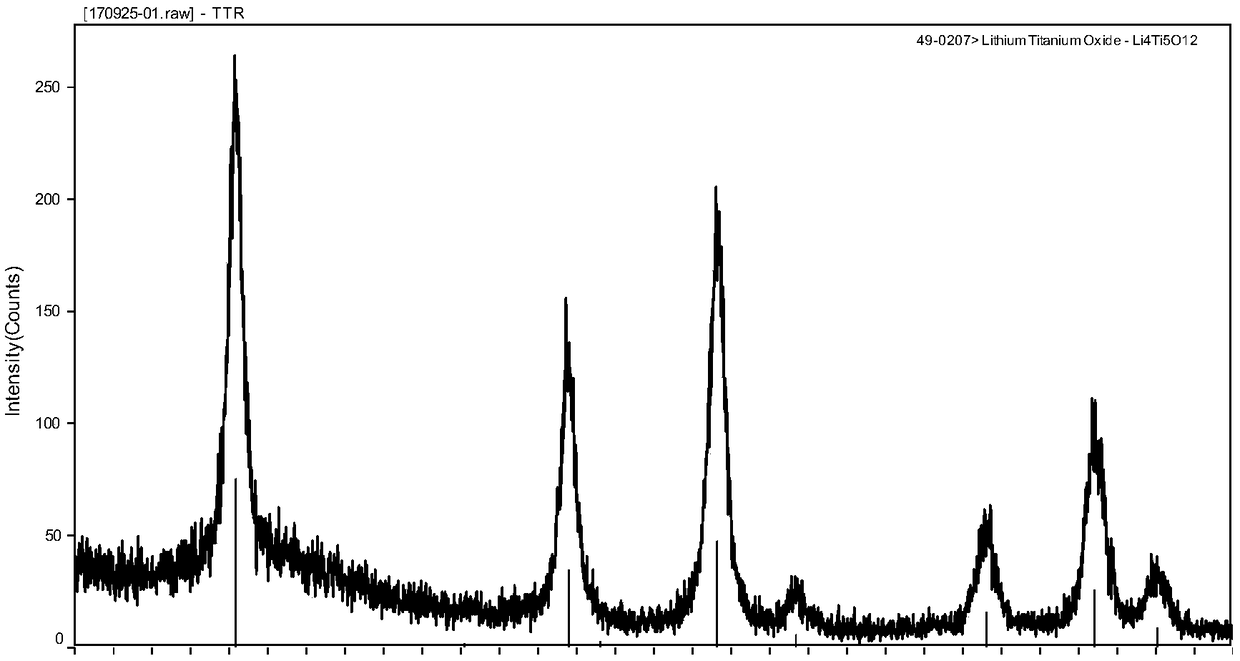

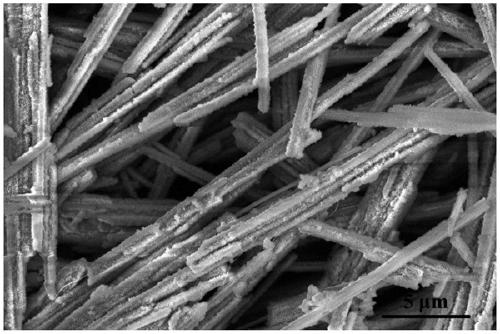

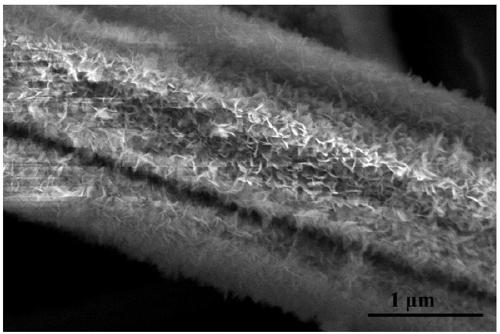

Embodiment 1

[0090] First, 2 g of titanium isopropoxide was dispersed in 100 ml of water, and then 5 ml of hydrogen peroxide with a concentration of 30% was added, and stirred to form a titanium-containing peroxo complex suspension. Next, 3.5 grams of lithium hydroxide was added to the suspension of the above-mentioned peroxo complex, and stirred to form a light yellow transparent solution. Subsequently, the above-mentioned light yellow transparent solution was heated to 80 degrees Celsius and then stirred at constant temperature for 6 hours to obtain a white product of lithium peroxotitanate with a linear structure. The reaction was stopped and separated and dried to obtain a white solid. Subsequently, the above-mentioned white solid was dispersed in 100 ml of water, and hydrothermally reacted at 120 degrees Celsius for 6 hours to obtain a lithium titanate precursor with a linear hierarchical structure. Finally, the linear hierarchical structure lithium titanate precursor obtained above w...

Embodiment 2

[0097] Firstly, 2 g of tetrabutyl titanate was dispersed in 100 ml of water, then 5 ml of 30% hydrogen peroxide was added, and stirred to form a titanium-containing peroxo complex suspension. Next, 3.5 grams of lithium hydroxide was added to the suspension of the above-mentioned peroxo complex, and stirred to form a light yellow transparent solution. Subsequently, the above-mentioned light yellow transparent solution was heated to 80 degrees Celsius and then stirred at constant temperature for 6 hours to obtain a white product of lithium peroxotitanate with a linear structure. The reaction was stopped and separated and dried to obtain a white solid. Subsequently, the above-mentioned dried white solid was placed in an oven at 150 degrees Celsius for 4 hours to obtain a linear structure lithium peroxytitanate with peroxide radicals removed from the surface. Next, the above-mentioned white solid was dispersed in 100 ml of water, and hydrothermally reacted at 120 degrees Celsius f...

Embodiment 3

[0103] First, 1 gram of titanic acid was dispersed in 100 ml of water, then 6 ml of 30% hydrogen peroxide was added, and stirred to form a titanium-containing peroxo complex suspension. Next, add 4 grams of lithium hydroxide to the suspension of the above-mentioned peroxo complex, and stir to form a light yellow transparent solution. Subsequently, the above light yellow transparent solution was heated to 90 degrees Celsius and then stirred at constant temperature for 5 hours to obtain a white product of lithium peroxotitanate with a linear structure. The reaction was stopped and separated and dried to obtain a white solid. Next, the above-mentioned white solid was dispersed in 100 ml of isopropanol to water in an alcoholic aqueous solution with a ratio of 1:5, and hydrothermally reacted at 100 degrees Celsius for 8 hours to obtain a lithium titanate precursor with a linear hierarchical structure. Finally, the linear hierarchical structure lithium titanate precursor obtained ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com