Graphene composite copper sulfide/nickel sulfide catalytic material and preparation method and application thereof

A graphene composite and catalytic material technology, applied in fuel cell type half cells and secondary cell type half cells, electrodes, electrical components, etc., can solve the problem of low abundance of precious metal elements, hindering industrial application, and poor cycle stability. and other problems, to achieve the effect of being conducive to market promotion, high-efficiency oxygen reduction and alcohol oxidation bifunctional catalytic performance, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

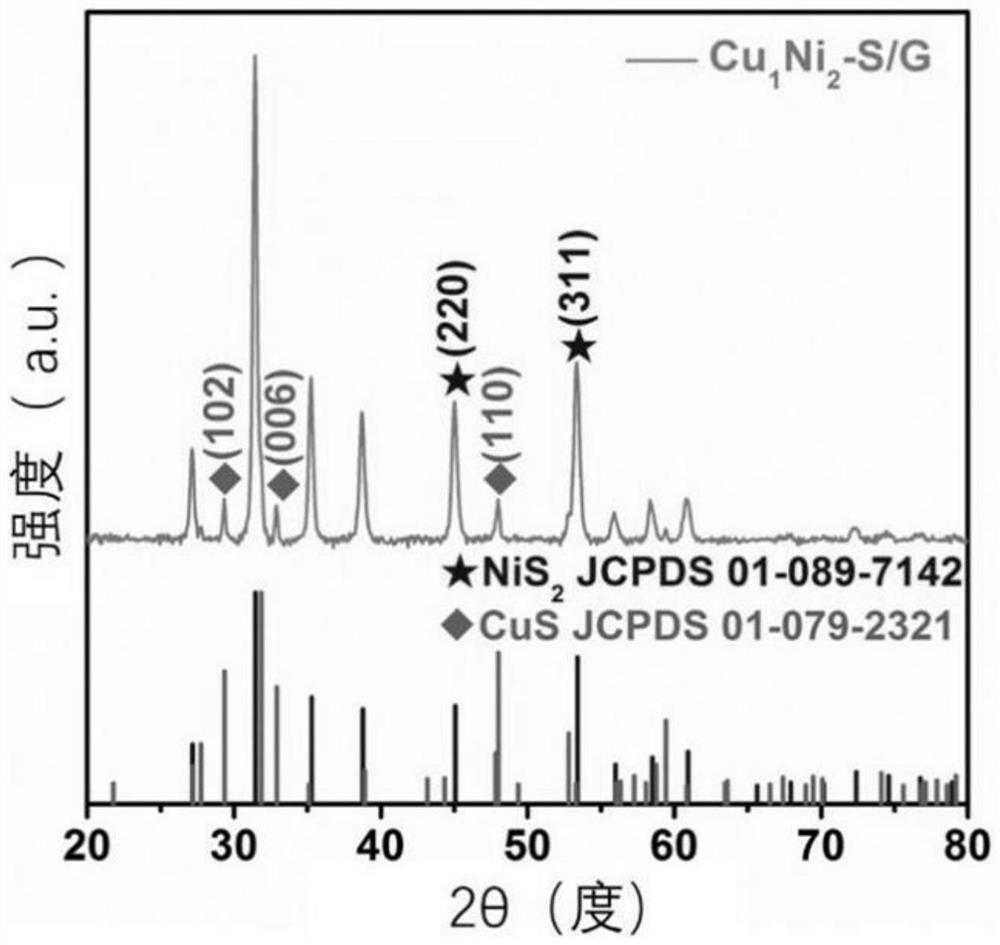

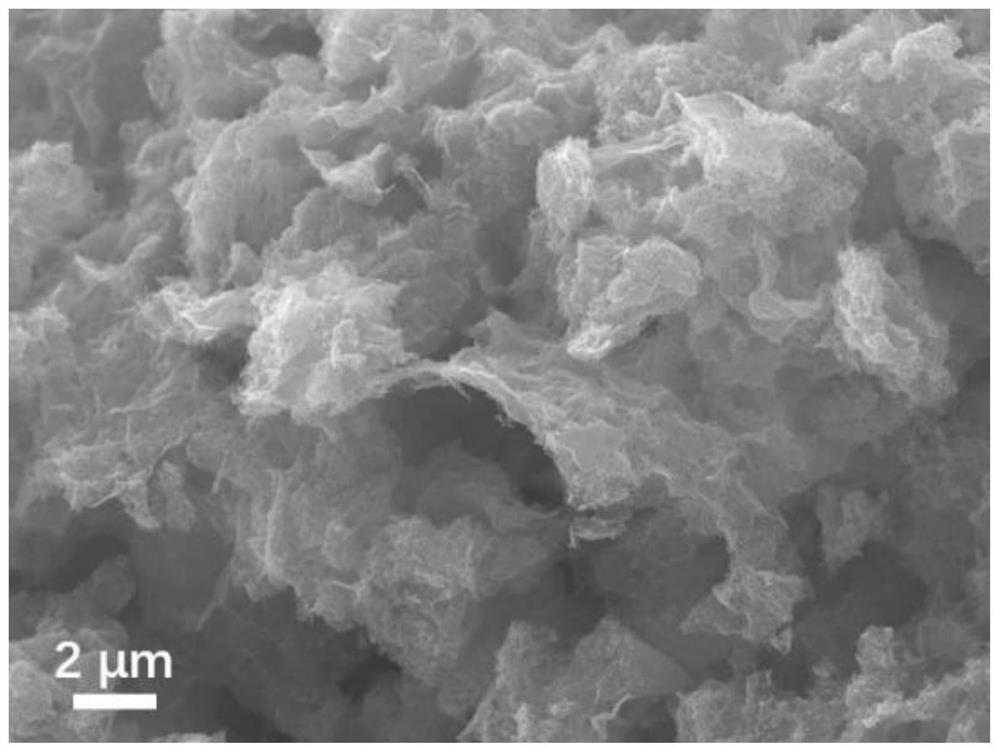

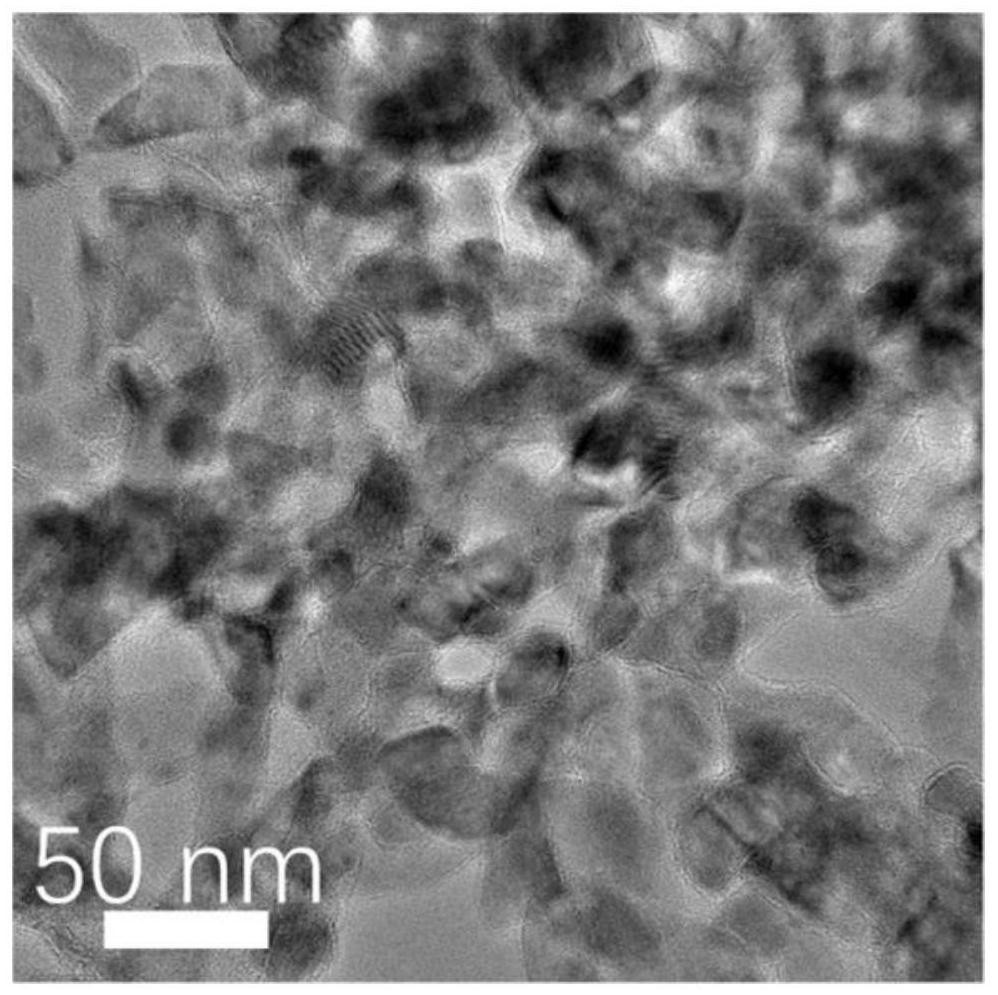

[0040] combine Figure 4 As shown, the embodiment of the present invention provides a method for preparing a graphene composite copper sulfide / nickel sulfide catalytic material, comprising the following steps:

[0041] S1, prepare graphene oxide dispersion liquid;

[0042] S2. Dissolve copper nitrate, nickel nitrate and urea in deionized water, stir evenly, add graphene dispersion, mix evenly to form a mixed solution;

[0043] S3, placing the mixed solution in a polytetrafluoroethylene reactor, performing a hydrothermal reaction, cooling to room temperature, washing with deionized water and ethanol, and drying to obtain a precursor powder;

[0044] S4. Put the precursor powder and the sulfur powder in two porcelain boats respectively, and calcinate them under an argon atmosphere to obtain a graphene composite copper sulfide / nickel sulfide catalytic material.

[0045] Specifically, in step S1, the graphene oxide dispersion can be prepared by a conventional method. In the pres...

Embodiment 1

[0067] The present embodiment provides the preparation method of graphene composite copper sulfide / nickel sulfide catalytic material, comprising the following steps:

[0068] 1) preparation concentration is 8mg / mL graphene oxide (GO) dispersion liquid by improved Hummers method;

[0069] 2) Weigh 1mmol Cu(NO 3 ) 2 , 2mmol Ni(NO 3 ) 2 Dissolve 6 mmol urea in 30 mL deionized water, stir for 20 minutes, take 0.8 mL of GO dispersion, add it dropwise to the solution, and stir for 20 minutes to form a mixed solution;

[0070] 3) Transfer the above mixed solution to the lining of a 50mL polytetrafluoroethylene reactor, react in an oven at 160°C for 6h, take out the precipitate after cooling to room temperature, wash with deionized water and ethanol for 3 times, and then place it at 60°C Dry in an oven at ℃ for 12 hours to obtain the precursor powder;

[0071] 4) 100 mg of precursor powder and 500 mg of sulfur powder were placed in two porcelain boats respectively, and calcined a...

Embodiment 2

[0085] This example provides Cu 1 Ni 2 -The preparation method of S material, comprises the following steps:

[0086] 1) Weigh 1mmol Cu(NO 3 ) 2 , 2mmol Ni(NO 3 ) 2 and 6mmol urea were dissolved in 30mL deionized water, and stirred for 20 minutes;

[0087] 2) Transfer the above mixed solution to the lining of a 50mL polytetrafluoroethylene reaction kettle, react in an oven at 160°C for 6h, take out the precipitate after cooling to room temperature, wash with deionized water and ethanol for 3 times, and then place it at 60°C Dry in an oven for 12 hours;

[0088] 3) Weigh 100 mg of the precursor powder prepared above and 500 mg of sulfur powder, place them in two porcelain boats respectively, and calcinate for 2 hours at 350°C under an argon atmosphere with a heating rate of 2°C / min, take them out after natural cooling, and obtain Copper Sulphide / Nickel Sulphide material, labeled as Cu 1 Ni 2 -S.

[0089] Cu prepared by embodiment 2 1 Ni 2 -S constitutes a three-elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com