Preparation method of lithium titanate composite negative electrode materials used by lithium ion batteries

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor specific capacity and cycle stability, and achieve the effects of overcoming poor charge and discharge performance, reducing reaction time, and lowering reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

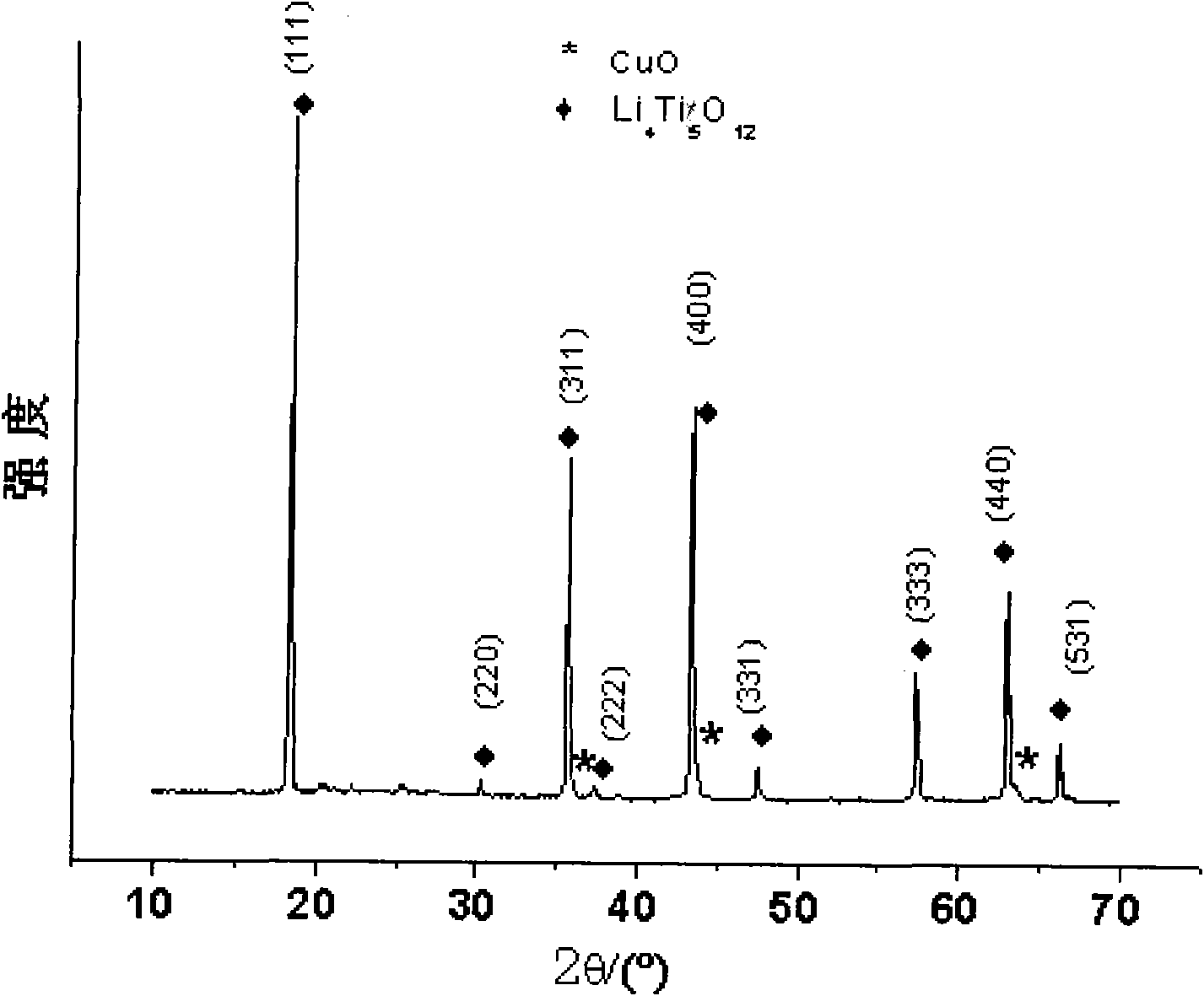

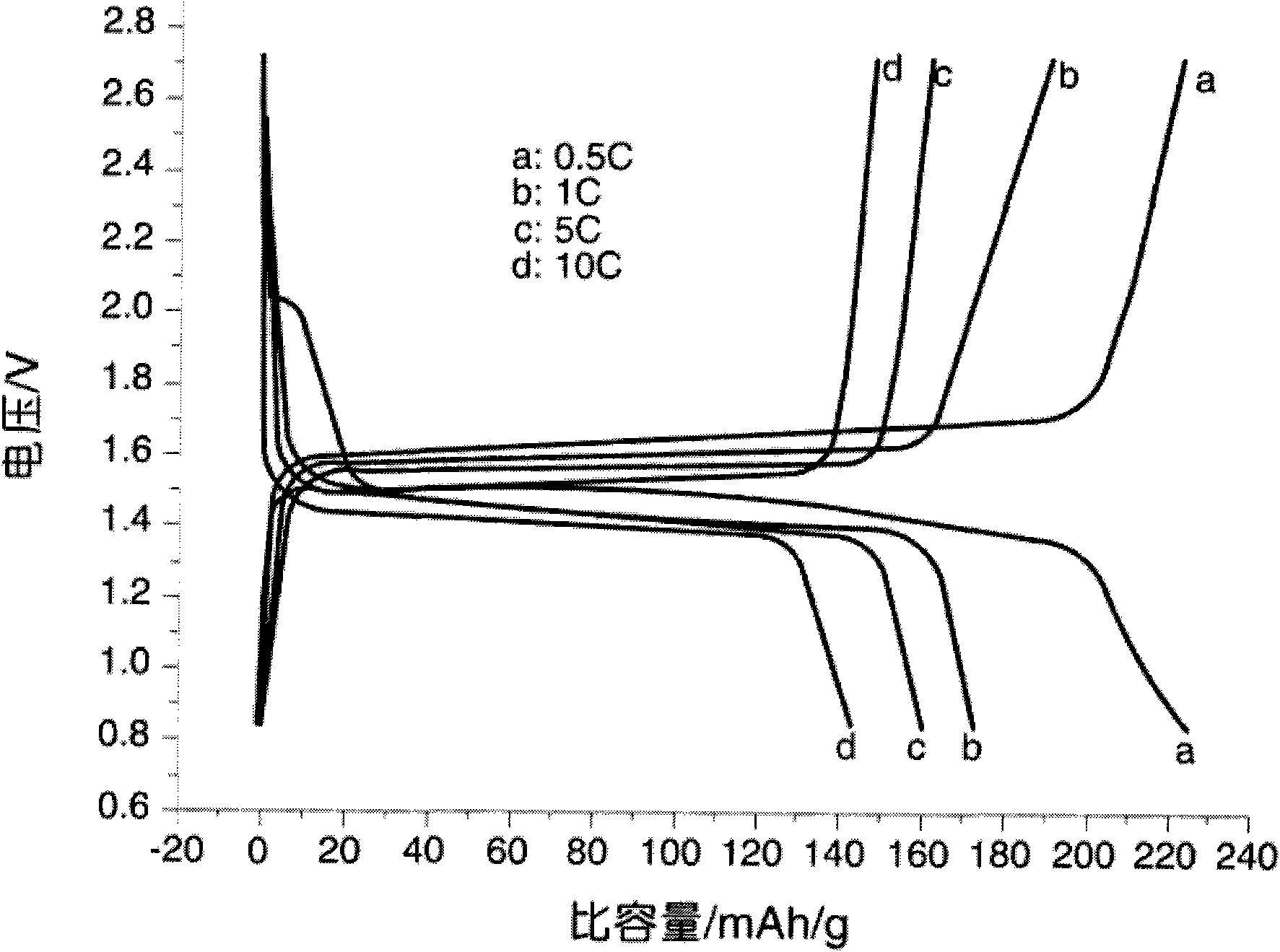

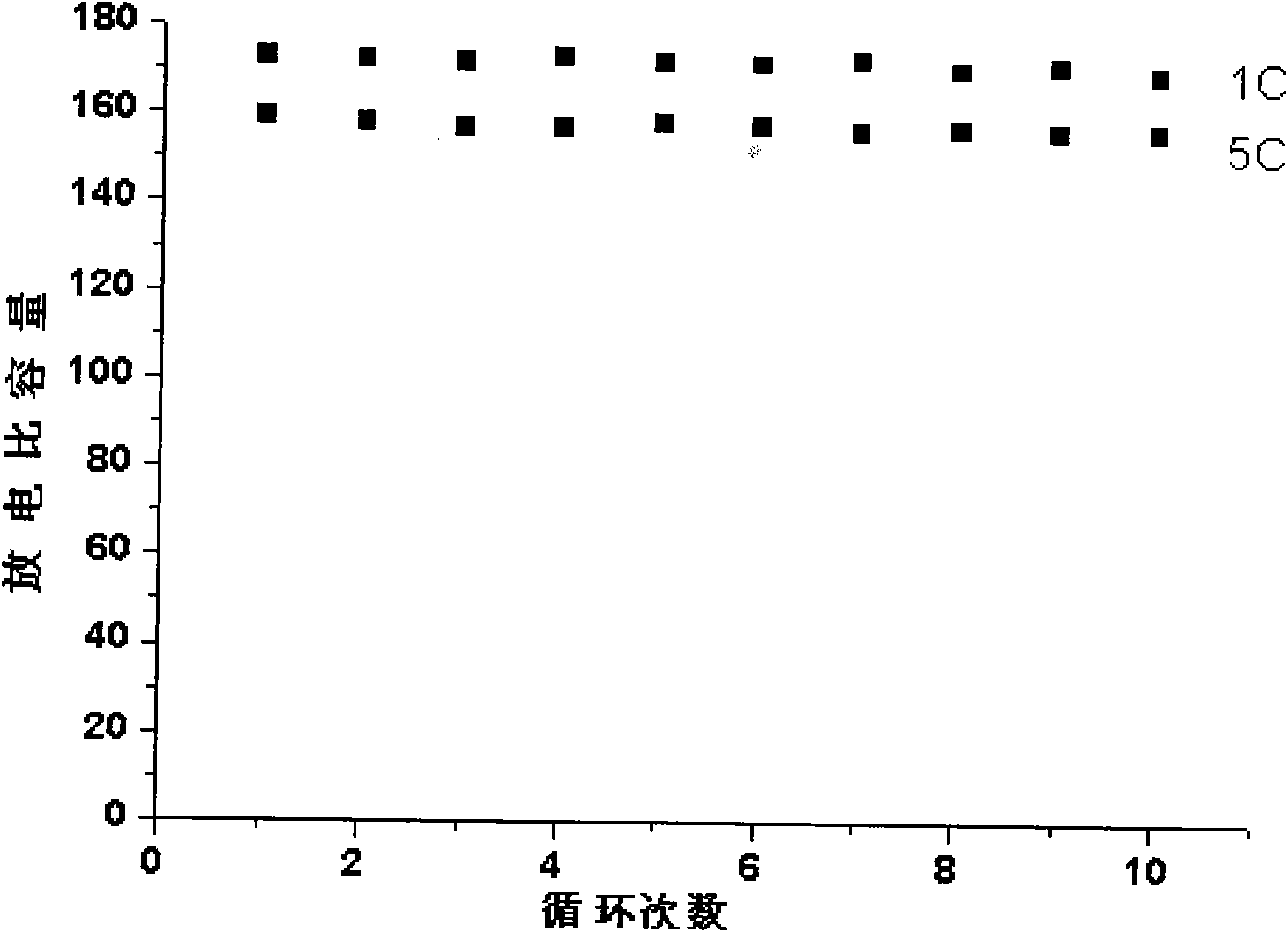

[0027] According to Li 4 Ti 5 o 12 The mass ratio of each element in is taken as 1.458g Li respectively 2 CO 3 Powder, 3.65g TiO 2 Put the powder and 10-20ml alcohol into the mixing tank, put it into a planetary ball mill for ball milling for 8 hours, take it out and dry it in an oven at 90°C for 8 hours, then put it in a crucible and put it in a box-type sintering furnace, in the air atmosphere to Raise the temperature to 750°C at a heating rate of 4°C / min, keep it warm for 6 hours, then continue to heat up to 850°C, keep it warm for 18 hours, then cool to room temperature with the furnace, take out the sample and ball mill again to get Li 4 Ti 5 o 12 , the prepared Li 4 Ti 5 o 12 Weigh 3g, and add 0.03g of copper acetate with 1% of the mass, put it into a drum-type powder ball mill for ball milling for 12 hours, take it out and dry it in an oven at 90°C for 12 hours, then put it in a crucible and put it in a box-type sintering furnace. The air atmosphere is directl...

Embodiment 2

[0031] According to Li 4 Ti 5 o 12 The mass ratio of each element in is taken as 1.458g Li respectively 2 CO 3 Powder, 3.65g TiO 2 Put the powder and 10-20ml alcohol into the mixing tank, put it into a planetary ball mill for ball milling for 9 hours, take it out and dry it in an oven at 100°C for 8 hours, then put it in a crucible and put it in a box-type sintering furnace. Raise the temperature to 600°C at a heating rate of 4°C / min, hold for 8 hours, then continue to heat up to 800°C, hold for 20 hours, then cool to room temperature with the furnace, take out the sample and ball mill again to obtain Li 4 Ti 5 o 12 , the above-prepared Li 4 Ti 5 o 12 Weigh 3g, and add 0.075g of copper oxide with 2.5% of the mass, put it into a drum-type powder ball mill for ball milling for 12 hours, take it out and dry it in an oven at 90°C for 12 hours, then put it in a crucible and put it in a box-type sintering furnace. The air atmosphere is directly heated to 400°C, held at 6 h...

Embodiment 3

[0035] According to Li 4 Ti 5 o 12 The mass ratio of each element in 0.932g LiOH (lithium hydroxide) powder, 3.65g TiO 2 Put the powder and 10-20ml alcohol into the mixing tank, put it into a planetary ball mill for ball milling for 12 hours, take it out and dry it in an oven at 90°C for 9 hours, then put it in a crucible and put it in a box-type sintering furnace. Raise the temperature to 750°C at a heating rate of 4°C / min, keep it warm for 6 hours, then continue to heat up to 900°C, keep it warm for 16 hours, then cool to room temperature with the furnace, take out the sample and ball mill again to get Li 4 Ti 5 o 12 , the above-prepared Li 4 Ti 5 o 12 Weigh 3g, and add 0.12g of copper acetate with 4% of the mass, put it into a drum-type powder ball mill for ball milling for 12 hours, take it out and dry it in an oven at 90°C for 12 hours, then put it in a crucible and put it in a box-type sintering furnace. The air atmosphere is directly heated to 450°C, kept for 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com