Method for preparing lithium titanate cathode material of lithium ion battery

A technology for lithium ion batteries and negative electrode materials, which is applied in electrode manufacturing, battery electrodes, circuits, etc., can solve the problems of unsuitable industrial application, high synthesis requirements and costs, and complicated operation processes, and achieves improved high-rate charge-discharge performance. The effect of large specific surface area and stable discharge specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

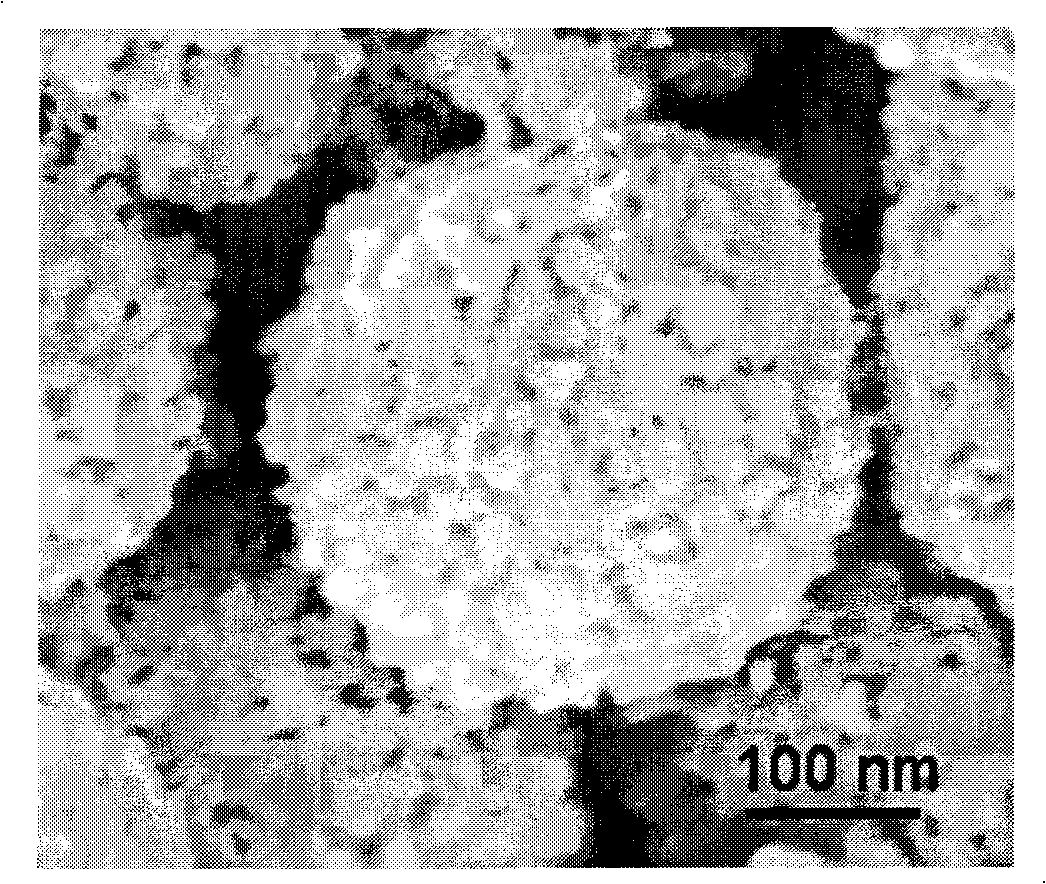

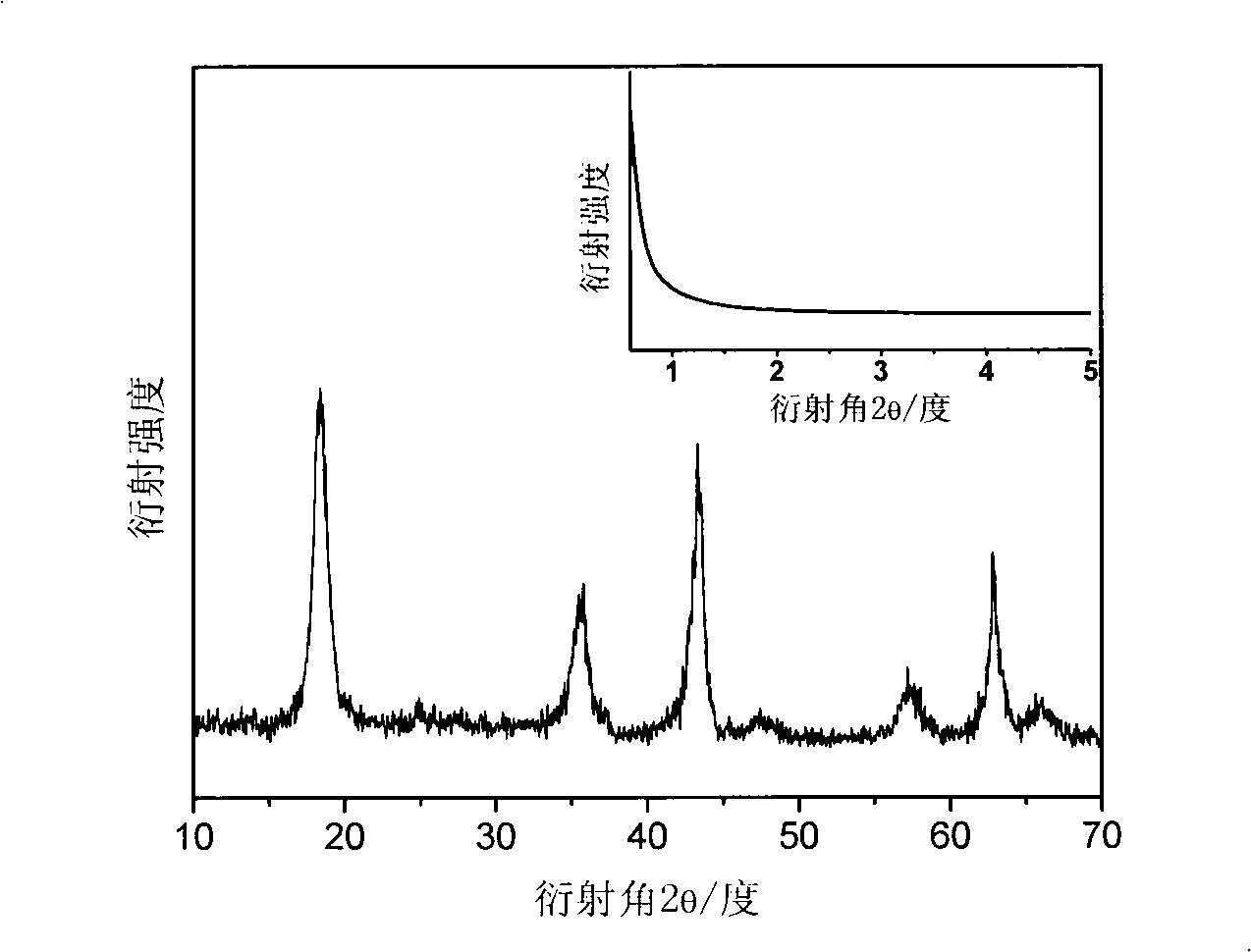

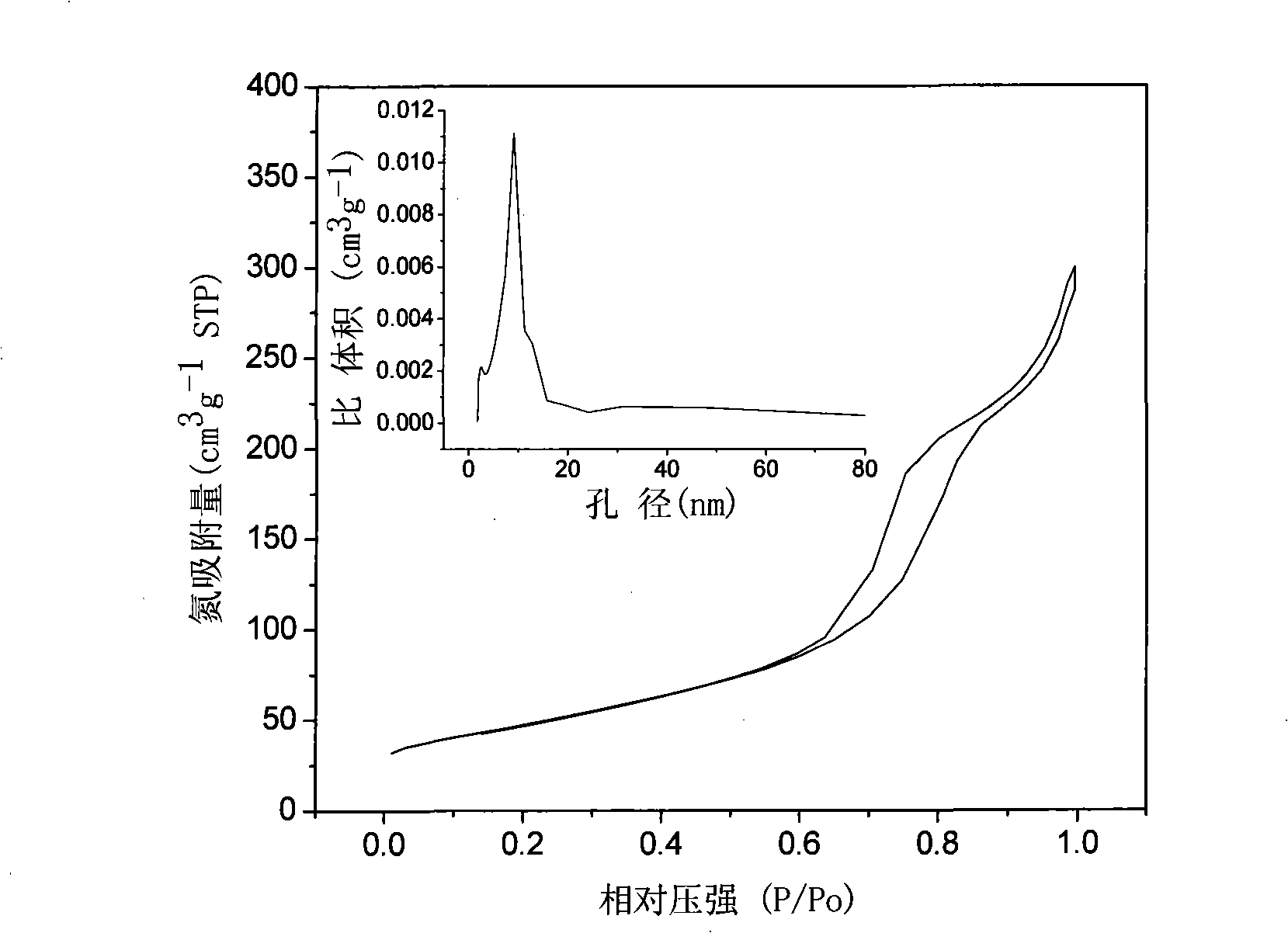

[0018] Under stirring condition, join 0.6g titanium dioxide colloid in the mixed solution of 50mL water and ethanol (volume ratio of water and ethanol is 1: 1), then add 0.15g lithium hydroxide under stirring condition, continue to stir after 5min The solution was transferred into a hydrothermal reaction kettle with a volume of 70mL, and then placed in a 180°C oven for hydrothermal ion exchange reaction for 12 hours. After the reaction, it was naturally cooled to room temperature, and then filtered to obtain a white precipitate. Heat treatment in a muffle furnace at 500° C. for 2 hours to obtain a lithium titanate negative electrode material used in lithium ion batteries. figure 1 It is a scanning electron microscope photo of the lithium titanate negative electrode material used in lithium ion batteries. The figure shows that the lithium titanate negative electrode material used in lithium ion batteries is composed of lithium titanate nanoparticles, and the particle size of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com