Method for preparing nano-graphite with electric arc method

A technology of nano-graphene and arc method, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of poor charge and discharge performance, and achieve excellent rate charge and discharge performance and migration path The effect of short and high rate charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

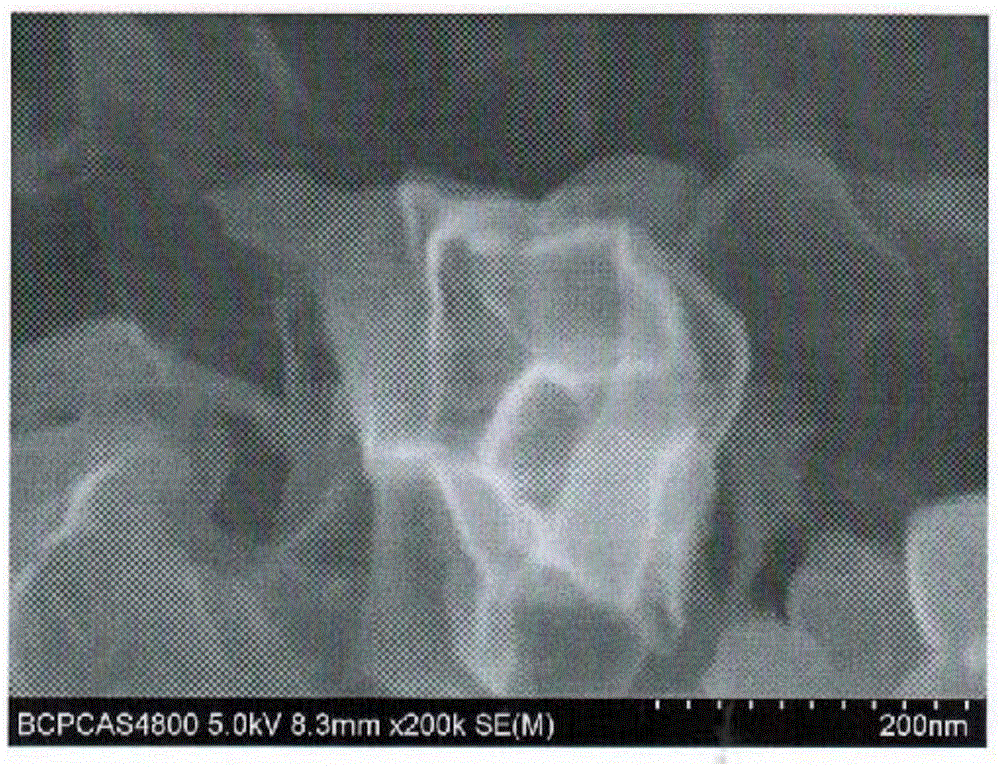

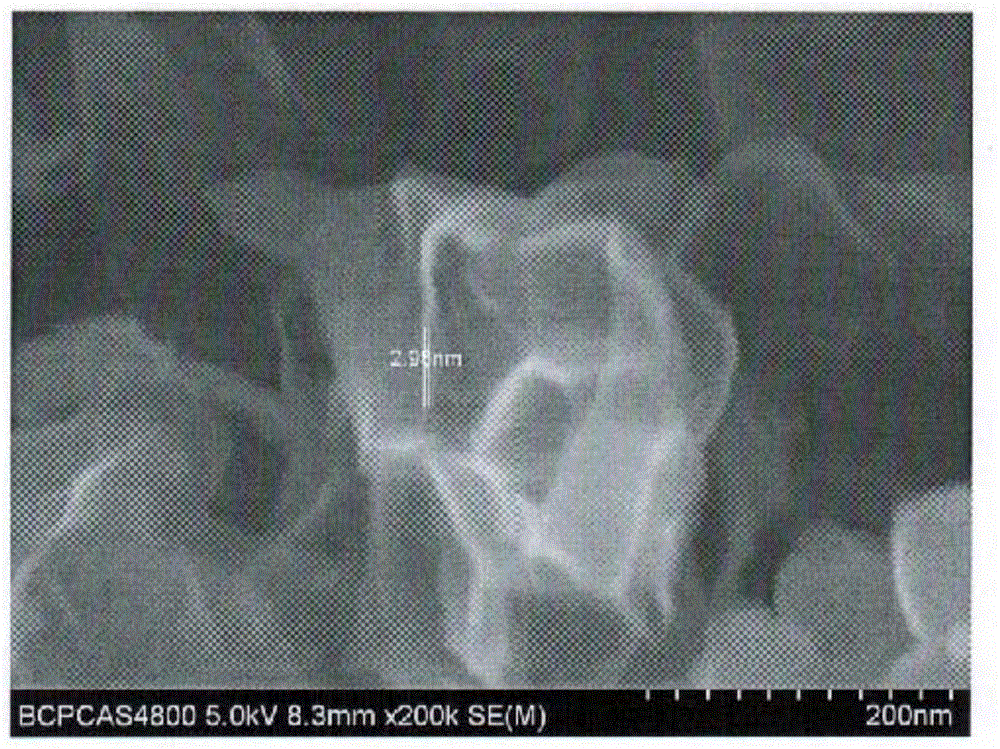

[0023] A method for preparing nano-graphene by an electric arc method is to use graphite rods as the cathode and anode poles of the nano-graphene prepared by the arc method, and perform arc discharge under high current and helium atmosphere. During the arc discharge process, the anode graphite rod is continuously consumed, High-purity 1-2 layers of nanometer graphene can be obtained in the inner wall area of the reaction chamber.

[0024] Among them, the graphite rod is a square spectrum pure ink electrode, and the size of the square spectrum pure ink electrode is 35mm*35mm*420mm. The two square spectrum pure ink electrodes are placed facing each other with a distance of 2mm.

[0025] Among them, the discharge current during arc discharge is 2200A, the arc temperature is 2500°C, and the pressure of the helium atmosphere is -6.5*10 -2 MPa.

[0026] Wherein, it also includes the step of burning the obtained graphene in the air to remove a small amount of amorphous carbon in ...

Embodiment 2

[0028] A method for preparing nano-graphene by an electric arc method is to use graphite rods as the cathode and anode poles of the nano-graphene prepared by the arc method, and perform arc discharge under high current and helium atmosphere. During the arc discharge process, the anode graphite rod is continuously consumed, High-purity 1-2 layers of nanometer graphene can be obtained in the inner wall area of the reaction chamber.

[0029] Among them, the graphite rod is a square spectrum pure ink electrode, and the size of the square spectrum pure ink electrode is 35mm*35mm*420mm. The two square spectrum pure ink electrodes are placed facing each other with a distance of 1 mm.

[0030] Among them, the discharge current during arc discharge is 1500A, the arc temperature is 3000°C, and the pressure of the helium atmosphere is -5*10 -2 MPa.

[0031] Wherein, it also includes the step of burning the obtained graphene in the air to remove a small amount of amorphous carbon in t...

Embodiment 3

[0033] A method for preparing nano-graphene by an electric arc method is to use graphite rods as the cathode and anode poles of the nano-graphene prepared by the arc method, and perform arc discharge under high current and helium atmosphere. During the arc discharge process, the anode graphite rod is continuously consumed, High-purity 1-2 layers of nanometer graphene can be obtained in the inner wall area of the reaction chamber.

[0034] Among them, the graphite rod is a square spectrum pure ink electrode, and the size of the square spectrum pure ink electrode is 35mm*35mm*420mm. The two square spectrum pure ink electrodes are placed opposite each other with a distance of 3mm.

[0035] Among them, the discharge current during arc discharge is 3000A, the arc temperature is 2800°C, and the pressure of the helium atmosphere is -10*10 -2 MPa.

[0036] Wherein, it also includes the step of burning the obtained graphene in the air to remove a small amount of amorphous carbon in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com