Lithium ion battery cathode material and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc. Improve stability, improve high current charge and discharge capacity, and facilitate industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

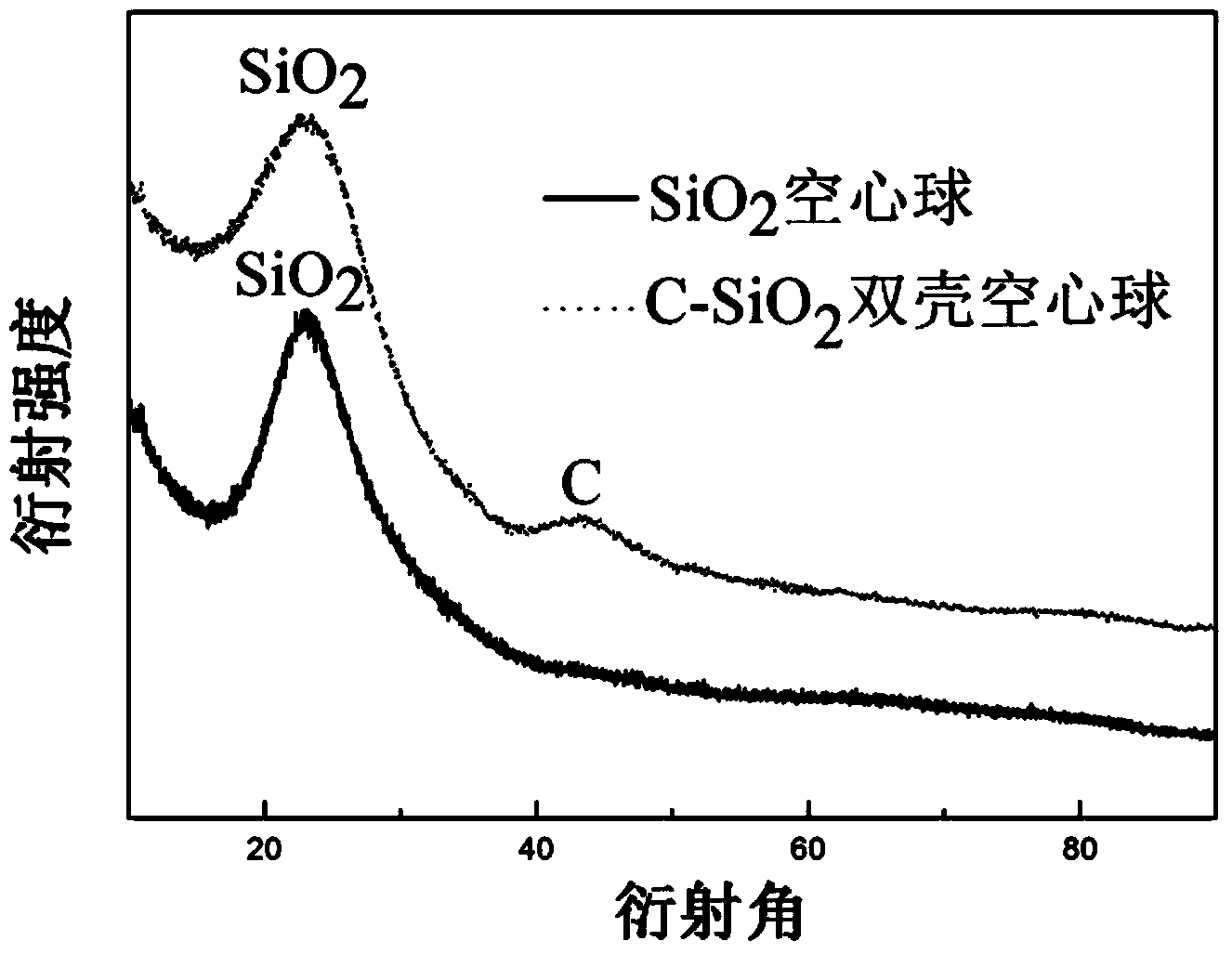

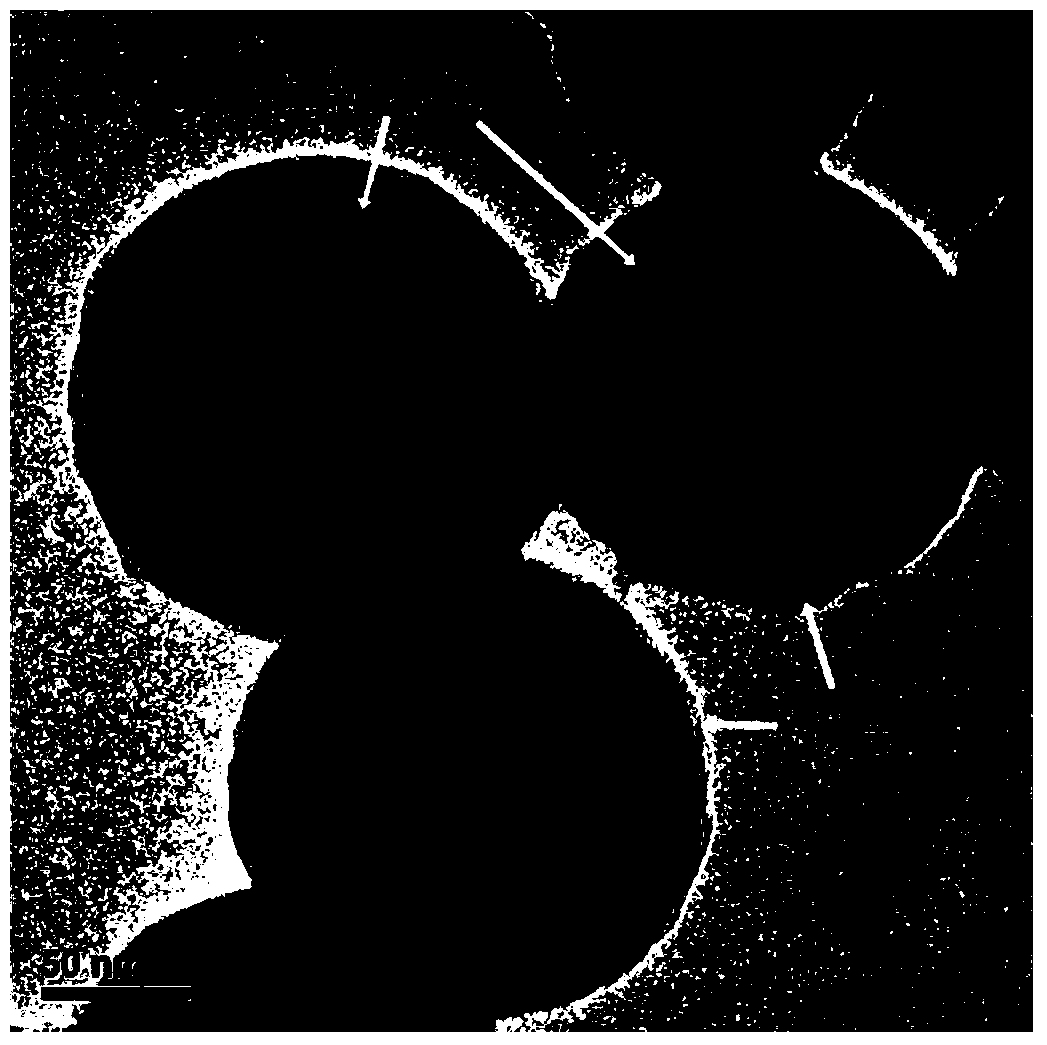

Embodiment 1

[0041] Preparation of negative electrode material: at room temperature, add 0.088g sodium dodecylbenzenesulfonate and 0.087g dodecylsulfobetaine to 10ml deionized water, and heat the solution to 40°C in a water bath environment. Stir for 1 hour; drop 55 μl of 3-aminopropyltriethoxysilane and 400 μl of tetraethyl orthosilicate into the above solution respectively, and stir for 2 hours; then heat the mixed solution to 70°C in an oil bath and keep it warm for 40 hours After the reaction, the product was collected by centrifugation, washed with ethanol and deionized water for several times, and dried; then the product was added to 50ml of concentrated hydrochloric acid (36% by mass) acetonitrile mixed solution (the volume ratio of hydrochloric acid to acetonitrile was 1: 3), stirring for 4 hours, washing with deionized water again, and drying to obtain a hollow spherical silica material. Add 0.1g of the obtained product into 10ml of pure water and stir, add 0.5g of glucose, stir f...

Embodiment 2

[0049] Preparation of negative electrode material: at room temperature, add 0.044g sodium dodecylbenzenesulfonate and 0.043g dodecyl sulfobetaine to 20ml deionized water, and heat the solution to 40°C in a water bath environment. Stir for 0.5 hours; drop 60 μl of 3-aminopropyltriethoxysilane and 600 μl of tetraethyl orthosilicate into the above solution respectively, and stir for 2 hours; then heat the mixed solution to 80°C in an oil bath and keep it warm for 20 hours After the reaction, the product was collected by centrifugation, washed with ethanol and deionized water for several times, and dried; then the product was added to 40ml of concentrated hydrochloric acid (38% by mass) acetonitrile mixed solution (the volume ratio of hydrochloric acid to acetonitrile was 1: 1), stirred for 6 hours, washed with deionized water again, and dried to obtain a silica hollow material. Add 0.2g of the obtained product into 10ml of pure water and stir, add 2g of sucrose, stir for 2 hours,...

Embodiment 3

[0051] Preparation of negative electrode material: at room temperature, add 0.017g sodium dodecylbenzenesulfonate and 0.017g dodecyl sulfobetaine to 30ml deionized water, and heat the solution to 50°C in a water bath environment. Stir for 2 hours; drop 50 μl of 3-aminopropyltriethoxysilane and 300 μl of tetraethyl orthosilicate into the above solution respectively, and stir for 0.5 hours; then heat the mixed solution to 90°C in an oil bath and keep it warm for 10 hours ; After the reaction, the product was collected by centrifugation, washed with ethanol and deionized water for several times, and dried; then the product was added to 30ml of concentrated hydrochloric acid (36% by mass) acetonitrile mixed solution (the volume ratio of hydrochloric acid to acetonitrile was 1: 2), stirring for 8 hours, washing with deionized water again, and drying to obtain a silica hollow material. Add 0.08g of the obtained product into 8ml of pure water and stir, add 1.5g of glucose, stir for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com