Granular electrode catalyst stuffing for 3D electrode reactor and its preparing method

A particle electrode and three-dimensional electrode technology, which is applied in the field of particle electrode catalyst filler and its preparation, can solve the problems of reducing the adsorption and oxidative decomposition of refractory organic matter, reducing the specific surface area of particle electrodes, and the number of hydroxyl radicals. Effects of reaction rate, relaxation of oxidation ability, and increase in anode area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

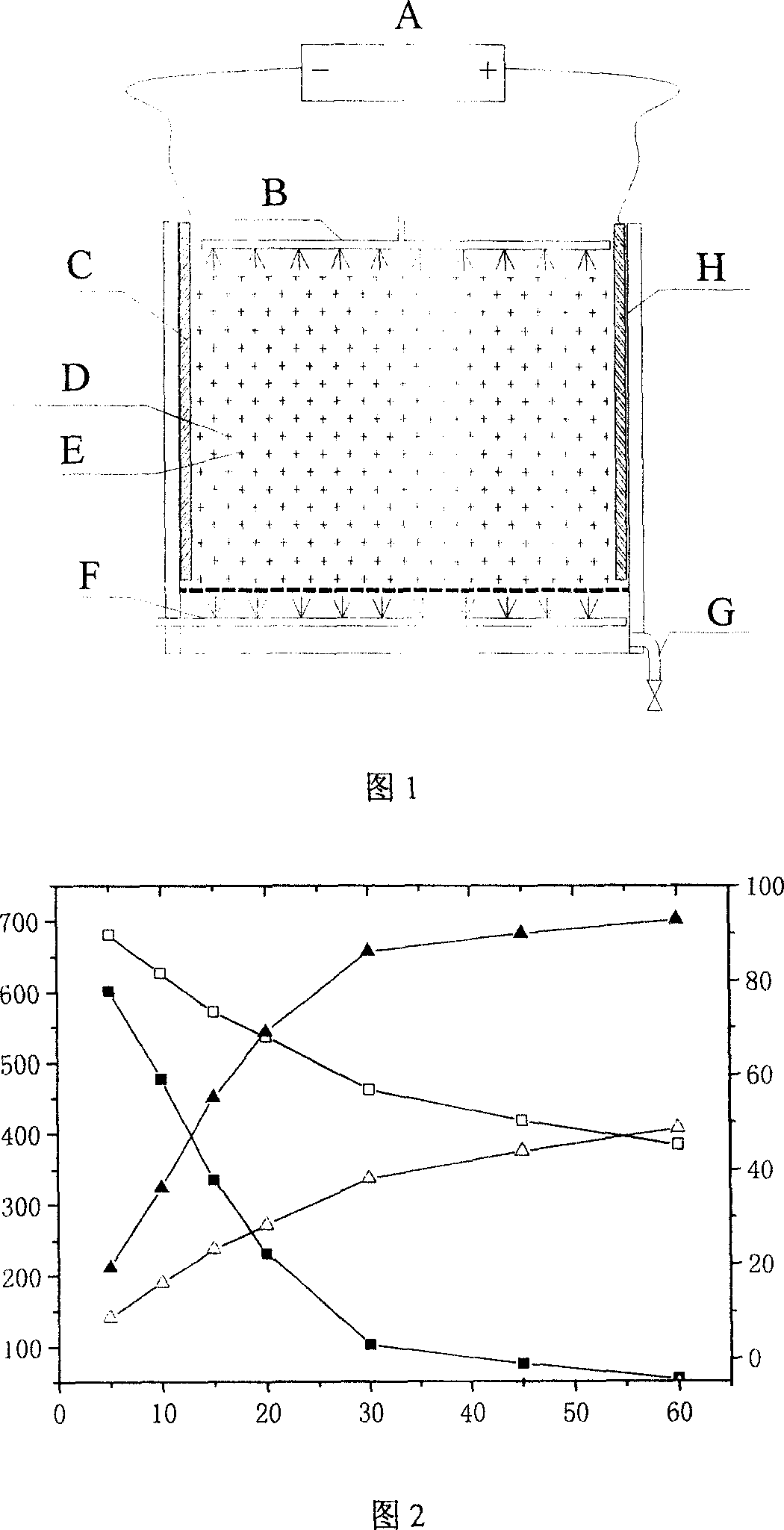

Method used

Image

Examples

Embodiment 1

[0025] The raw activated carbon is soaked in 8% hydrochloric acid solution at normal temperature for 6 hours and then washed to neutral, dried at 150°C for 1 hour, then soaked in 8% sodium hydroxide solution for 6 hours at normal temperature and washed to neutral. Neutral, dry at 150°C for 1 hour to make acid-base modified activated carbon; add the acid-base modified activated carbon to a hydrogen peroxide solution with a mass concentration of 12%, heat to 50°C and stir for 1.5 hours, filter after cooling, and use Wash with deionized water until neutral; add the oxidatively modified activated carbon to a mixed solution containing 0.2mol / L copper nitrate salt and 0.3mol / L iron nitrate, stir and impregnate at room temperature for 6h, then dry at 115°C After 1h, at N 2 Modified activated carbon was obtained after roasting at 420°C for 3 hours; acid-base modified activated carbon was added to 0.15% cellulose acetate solution, soaked for 0.5h, and dried to make coated activated car...

Embodiment 2

[0027] The raw activated carbon is soaked in a hydrochloric acid solution with a mass concentration of 10% at room temperature for 9 hours and then washed to neutrality, dried at 180°C for 2 hours, and then soaked in a sodium hydroxide solution with a mass concentration of 10% at room temperature for 9 hours and then washed to Neutral, dry at 180°C for 2 hours to make acid-base modified activated carbon; add the acid-base modified activated carbon into a hydrogen peroxide solution with a mass concentration of 13%, heat to 60°C and stir for 1.5h, filter after cooling, and use Wash with deionized water until neutral; add the oxidatively modified activated carbon to a mixed solution containing 0.4 mol / L copper nitrate salt and 0.5 mol / L iron nitrate, stir and impregnate at room temperature for 8 hours, then dry at 120°C After 2h, at N 2 The modified activated carbon was obtained after roasting at 400°C for 4 hours; the acid-base modified activated carbon was added to 0.2% cellulo...

Embodiment 3

[0029] The raw activated carbon is soaked in hydrochloric acid solution with a mass concentration of 9% at room temperature for 8 hours, washed to neutrality, dried at 180° C. for 2 hours, and then soaked with potassium hydroxide with a mass concentration of 9% (an example of potassium hydroxide is given). ) solution at room temperature for 8 hours, washed to neutrality, and dried at 180°C for 2 hours to make acid-base modified activated carbon; add the acid-base modified activated carbon into a hydrogen peroxide solution with a mass concentration of 15%, and heat to 60°C Stir for 1.5h, filter after cooling, wash with deionized water until neutral; add the activated carbon that has been oxidized and modified into a mixed solution containing 0.5mol / L copper chloride salt and 0.4mol / L ferric chloride, at room temperature After impregnating under stirring for 8 hours, drying at 120°C for 2 hours, and roasting in He atmosphere at 390°C for 4 hours to obtain modified activated carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com