Anode material for double-shell capsule-shaped silicon-based lithium-ion battery and preparation method of anode material

A negative electrode material, ion battery technology, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc., can solve problems such as taking into account electrochemical properties, reduce migration distance, and improve cycle stability. , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of capsule-like structure silica-coated silicon material template by surfactant soft template method:

[0039]At room temperature, mix 0.088g sodium dodecylbenzenesulfonate and 0.086g dodecyl sulfobetaine in a molar ratio of 1:1, add 10ml deionized water, and stir magnetically for 2 hours; then, mix 10ml silicon The powder suspension (8mg / ml) was added dropwise into the above mixed surfactant solution, and the stirring was continued during this process; the above solution was heated to 40°C in a water bath environment, and stirred for 2 hours; the 3-aminopropyl tris Add 94 μl of ethoxysilane and 300 μl of tetraethyl orthosilicate to the above solution respectively, and stir for 0.5 hours; then heat the mixed solution to 90°C in an oil bath and keep it warm for 48 hours; after the reaction, collect the product by centrifugation , washed the product with ethanol and deionized water respectively, and dried; then the product was added to 30ml of concentrated hyd...

Embodiment 2

[0041] Preparation of negative electrode material:

[0042] Add 0.3 g of the capsule-shaped silica-coated silicon template obtained in Example 1 into 25 ml of pure water and stir, add 1 g of glucose, stir for 1 hour, pour the solution into a 50 ml reaction kettle, and keep it in an oven at 180°C for 5 hours. After the end, the product was washed several times with ethanol and deionized water, and dried. Spread the dried product on a corundum porcelain boat (other refractory containers can be used instead of the corundum porcelain boat), sinter at 700° C. for 8 hours in an argon atmosphere, and cool to obtain an intermediate product. Then the obtained product was added into 20% hydrofluoric acid solution and stirred for 3 hours to obtain a capsule-shaped double-layer carbon-coated silicon nanocomposite material.

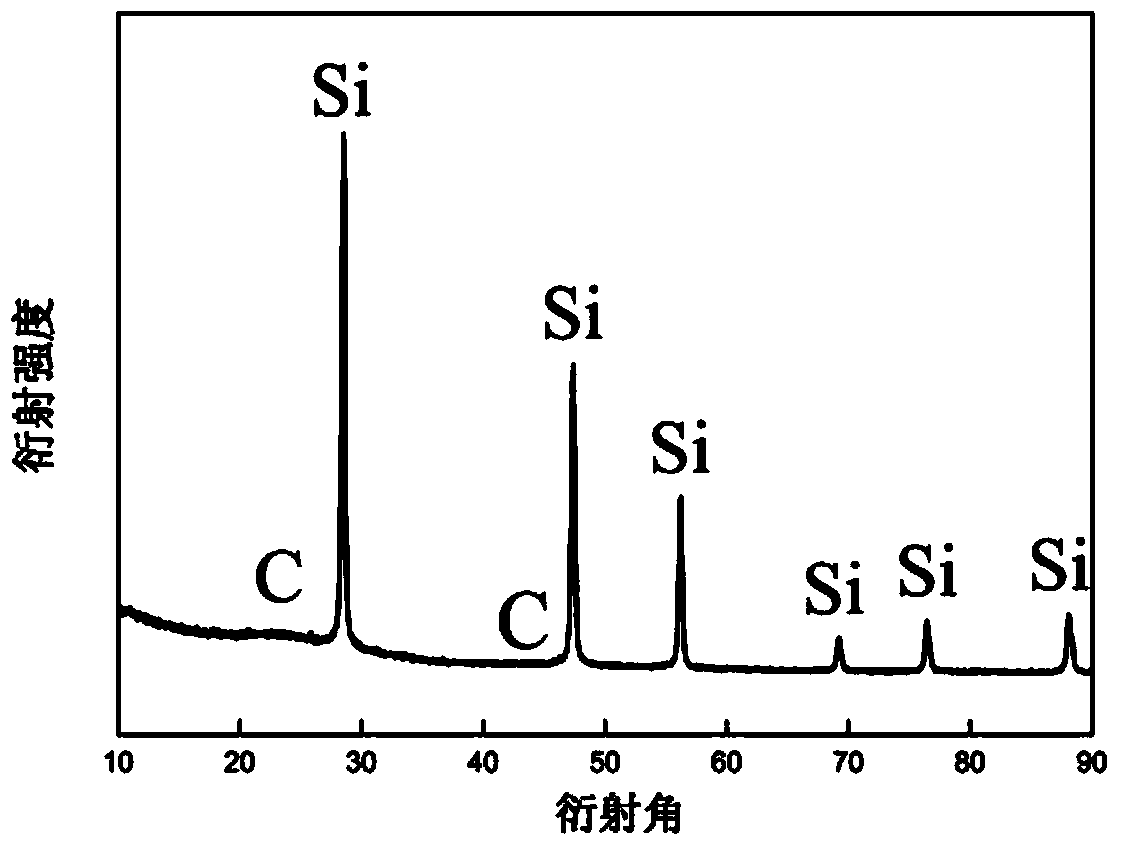

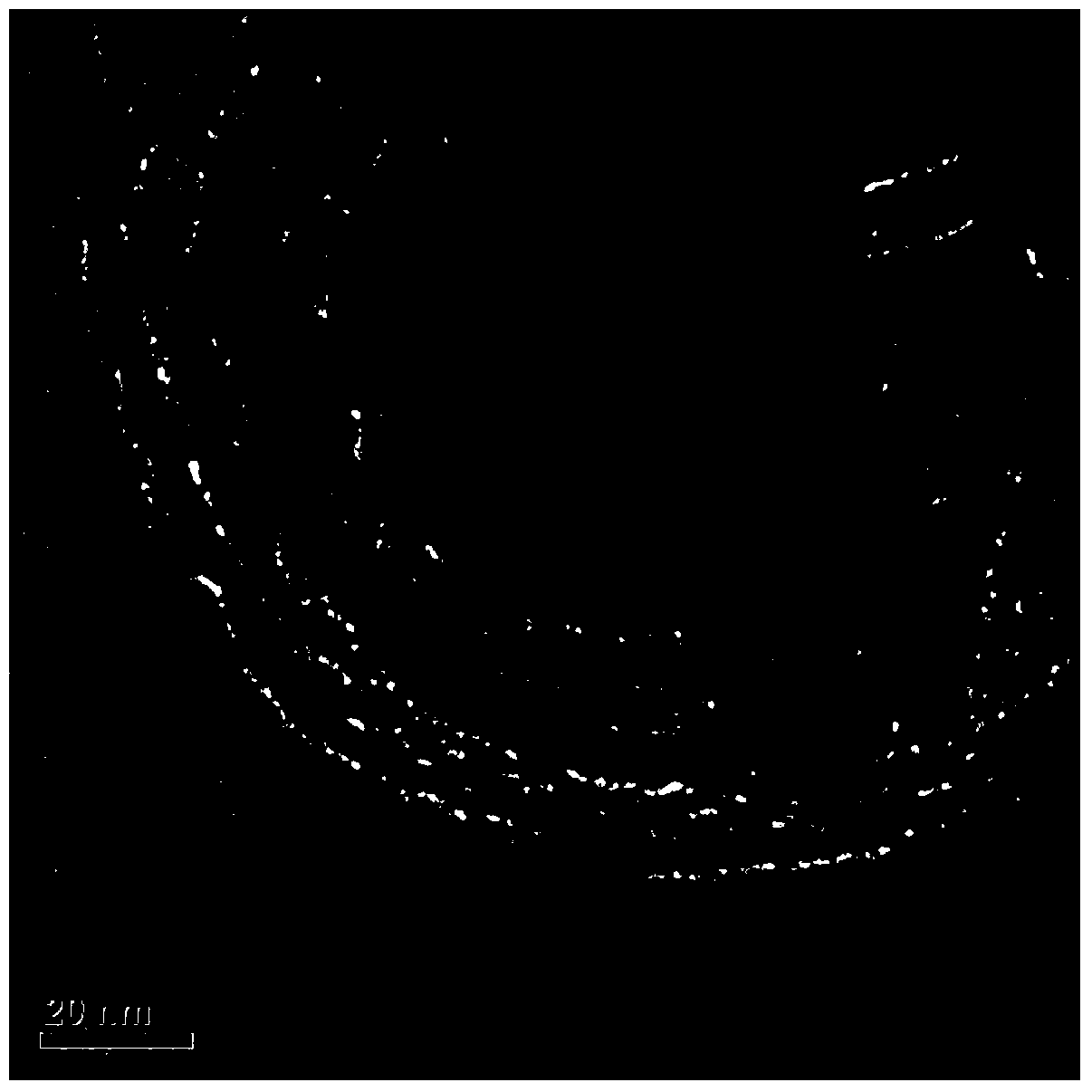

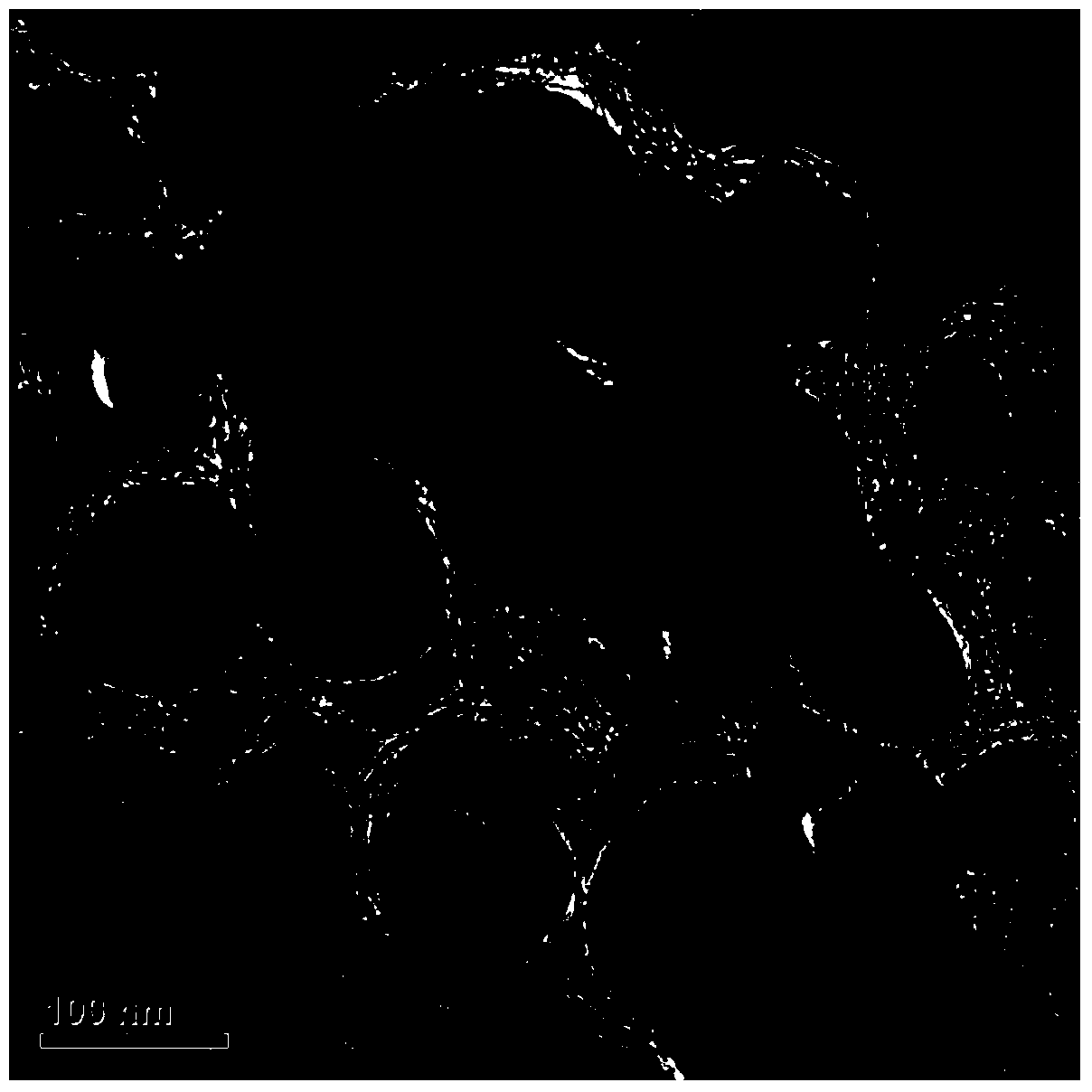

[0043] figure 1 is the X-ray diffraction pattern of the obtained sample, from figure 1 It can be seen from the above that, in addition to a broad peak at 23°, ther...

Embodiment 3

[0049] Add 0.1g of the product obtained in Example 1 into 15ml of pure water and stir, add 1g of glucose, stir for 1 hour, pour the solution into a 20ml reaction kettle, and keep it in an oven at 200°C for 2 hours. After the reaction, the product is washed with ethanol and deionized Wash with water several times and dry. Spread the dried product in a corundum porcelain boat (other refractory containers can be used instead of the corundum porcelain boat), sinter at 600° C. for 10 hours in an argon atmosphere, and cool to obtain an intermediate product. Then the obtained product was added into 5% hydrofluoric acid solution and stirred for 6 hours to obtain a capsule-shaped double-layer carbon-coated silicon nanocomposite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com