Carbon nitride-supported molybdenum nitride nanoparticle photocatalyst, and preparation method and application thereof

A nanoparticle and photocatalyst technology, applied in the field of materials science, can solve the problems of few surface active sites, easy recombination of photogenerated carriers, photolysis of water and hydrogen evolution performance, etc., to improve the catalytic process, good photogenerated charge separation efficiency, reduce Effect of charge transfer distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

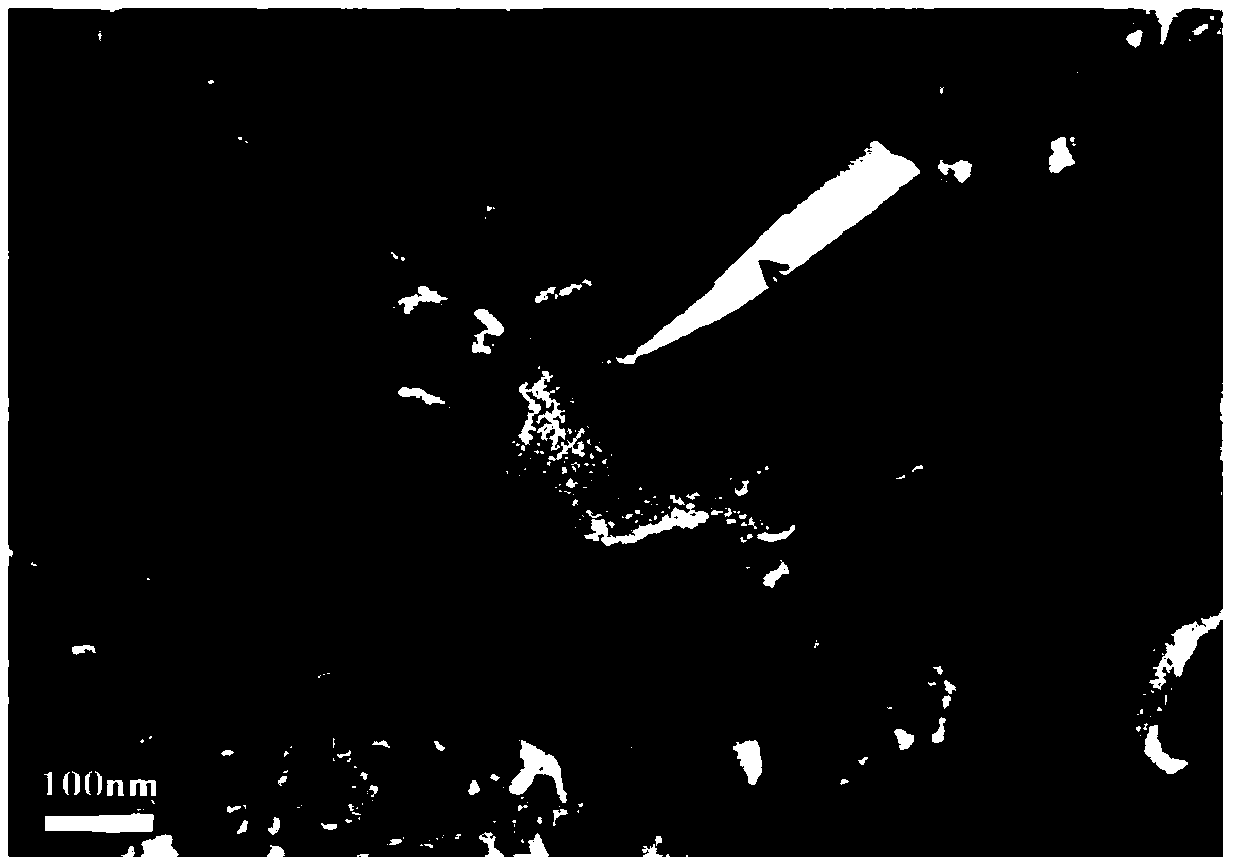

[0080] A carbon nitride-supported molybdenum nitride nanoparticle photocatalyst mainly contains three main elements of Mo, C and N, and is prepared by a method comprising the following steps:

[0081] (1), preparation of ultra-thin carbon nitride (hereinafter referred to as CN)

[0082] Add 1g of urea into 10ml of double-distilled water, stir and dissolve to obtain a 0.1g / ml aqueous urea solution, then use 1M HCl aqueous solution to adjust the pH to 4-5, stir for 10 minutes, then control the temperature to 70°C and dry it, then in N 2 Under the atmosphere, the heating rate is controlled at 5°C / min, and the temperature is raised to 520°C for calcination for 4 hours to obtain ultra-thin CN;

[0083] (2), molybdenum nitride (hereinafter referred to as Mo 2 N) preparation

[0084] Add 3g of ammonium molybdate tetrahydrate into 50ml of double-distilled water, stir in an oil bath at 40°C until clarification, and obtain an aqueous ammonium molybdate solution with a concentration of...

Embodiment 2

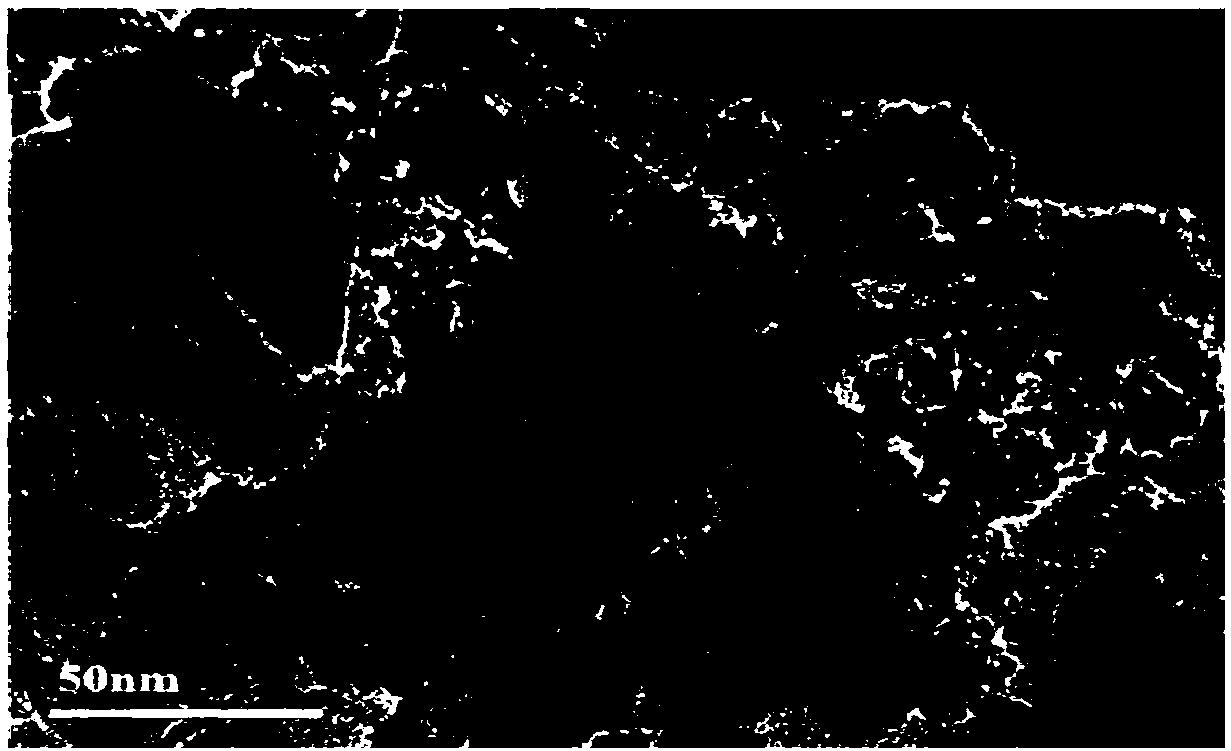

[0107] A carbon nitride-supported molybdenum nitride nanoparticle photocatalyst mainly contains three main elements of Mo, C and N, and is prepared by a method comprising the following steps:

[0108] (1), preparation of ultra-thin carbon nitride (hereinafter referred to as CN)

[0109] Add 1g of urea into 10ml of double-distilled water, stir and dissolve to obtain a 0.1g / ml aqueous urea solution, then use 1M HCl aqueous solution to adjust the pH to 4-5, stir for 10 minutes, then control the temperature to 70°C and dry it, then in N 2 Under the atmosphere, the heating rate is controlled at 5°C / min, and the temperature is raised to 520°C for calcination for 4 hours to obtain ultra-thin CN;

[0110] (2), molybdenum nitride (hereinafter referred to as Mo 2 N) preparation

[0111] Add 3g of ammonium molybdate tetrahydrate into 50ml of double-distilled water, stir in an oil bath at 40°C until clarification, and obtain an aqueous ammonium molybdate solution with a concentration of...

Embodiment 3

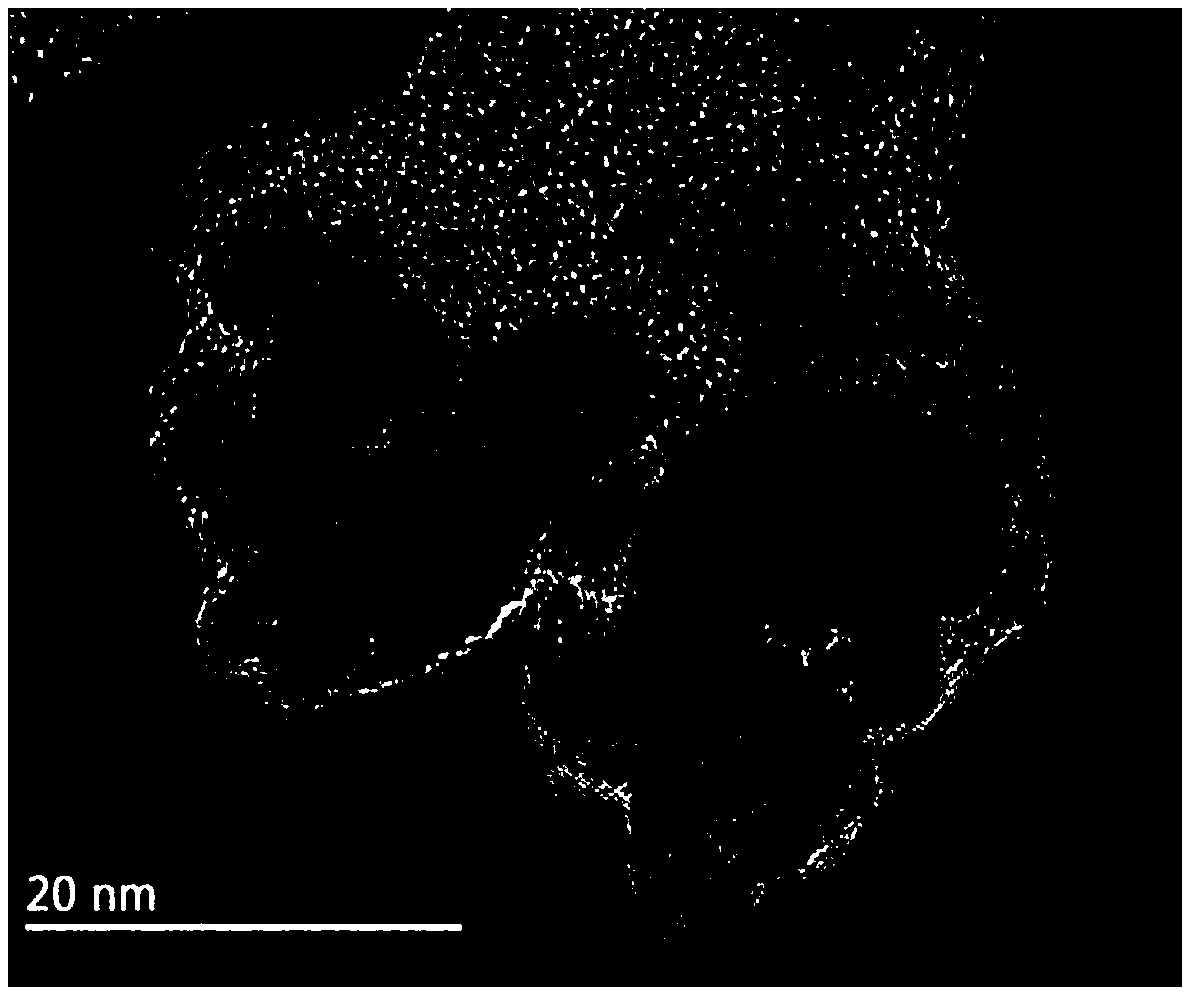

[0129] A carbon nitride-supported molybdenum nitride nanoparticle photocatalyst mainly contains three main elements of Mo, C and N, and is prepared by a method comprising the following steps:

[0130] (1), preparation of ultra-thin carbon nitride (hereinafter referred to as CN)

[0131] Add 1g of urea into 10ml of double-distilled water, stir and dissolve to obtain a 0.1g / ml aqueous urea solution, then use 1M HCl aqueous solution to adjust the pH to 4-5, stir for 10 minutes, then control the temperature to 70°C and dry it, then in N 2 Under the atmosphere, the heating rate is controlled at 5°C / min, and the temperature is raised to 520°C for calcination for 4 hours to obtain ultra-thin CN;

[0132] (2), molybdenum nitride (hereinafter referred to as Mo 2 N) preparation

[0133] Add 3g of ammonium molybdate tetrahydrate into 50ml of double-distilled water, stir in an oil bath at 40°C until clarification, and obtain an aqueous ammonium molybdate solution with a concentration of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com