Positive electrode piece, negative electrode piece of lithium ion capacitance battery and manufacture method of two electrode pieces thereof

A capacitive battery and its manufacturing method technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of shortened service life of the battery, long fast charging and discharging time, short circuit between the negative electrode and the positive electrode, etc., and achieve improved charging efficiency, smooth migration, The effect of reducing the formation of lithium dendrites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

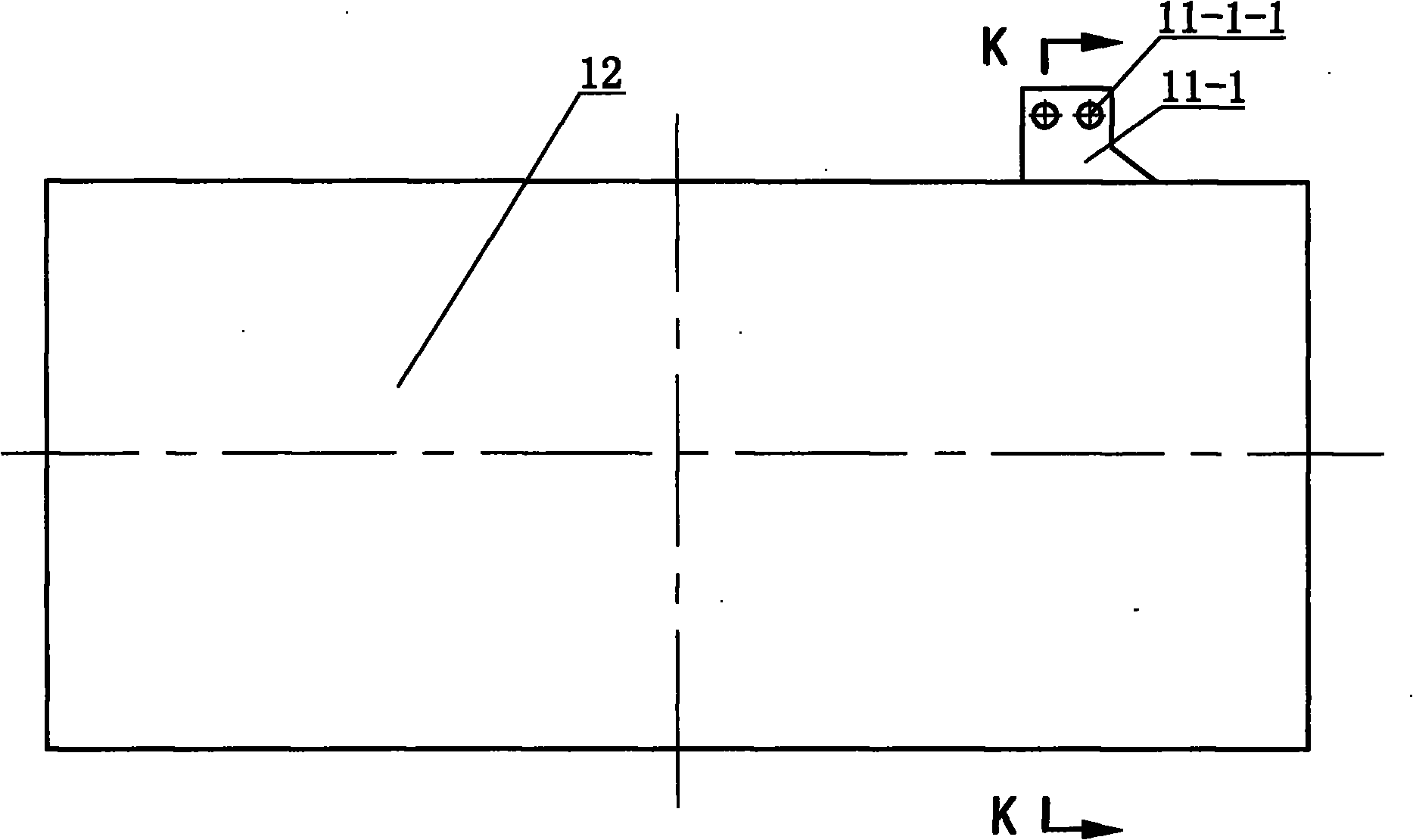

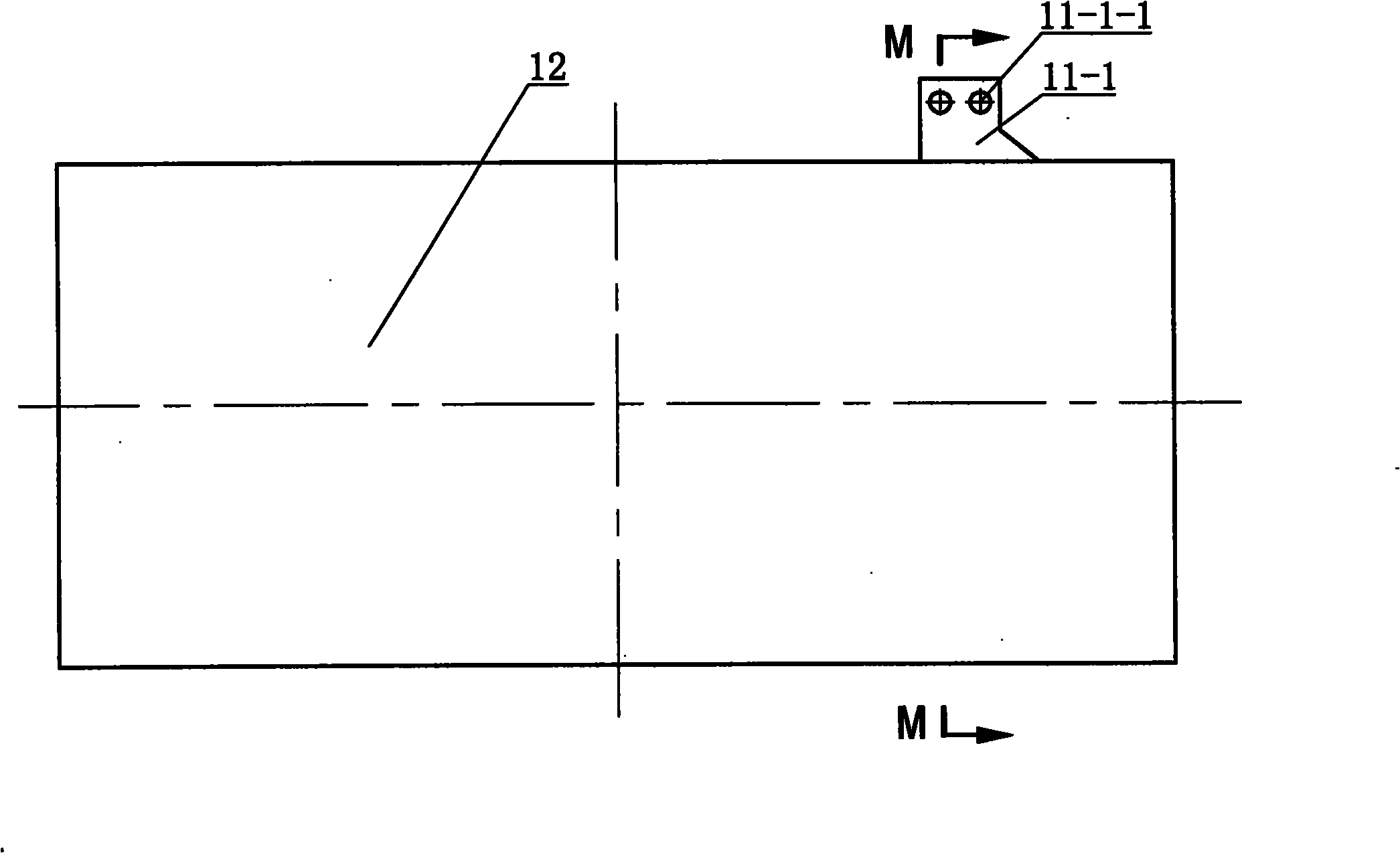

[0033] like Figure 9 to Figure 11 As shown, a positive electrode sheet of a lithium ion capacitor battery includes a positive electrode substrate 11 and a positive electrode material layer 12 coated on both sides of the positive electrode substrate 11, the positive electrode substrate 11 and the positive electrode material layer 12 on both sides are uniform The coated activated carbon layer 13 is sandwiched, and the activated carbon layer 13 on the inside and the positive electrode material layer 12 on the outside form the positive electrode coating 14 . The positive electrode coating 14 on the positive electrode substrate 11 is made up of several positive electrode coating blocks 15 arranged at intervals, and the shape of the positive electrode coating blocks 15 is all square or all rectangular, with uncoated void16. The positive electrode substrate 11 is aluminum foil, the positive electrode material layer 12 is a positive electrode material layer made of lithium iron phos...

Embodiment 2

[0045] This embodiment is basically the same as Embodiment 1. the difference is:

[0046] like Figure 9 to Figure 11 As shown, in a positive electrode sheet of a lithium-ion capacitor battery and its manufacturing method, the positive electrode material layer 12 is still a positive electrode material layer made of lithium iron phosphate material, but the thickness of the activated carbon layer 13 is 12um.

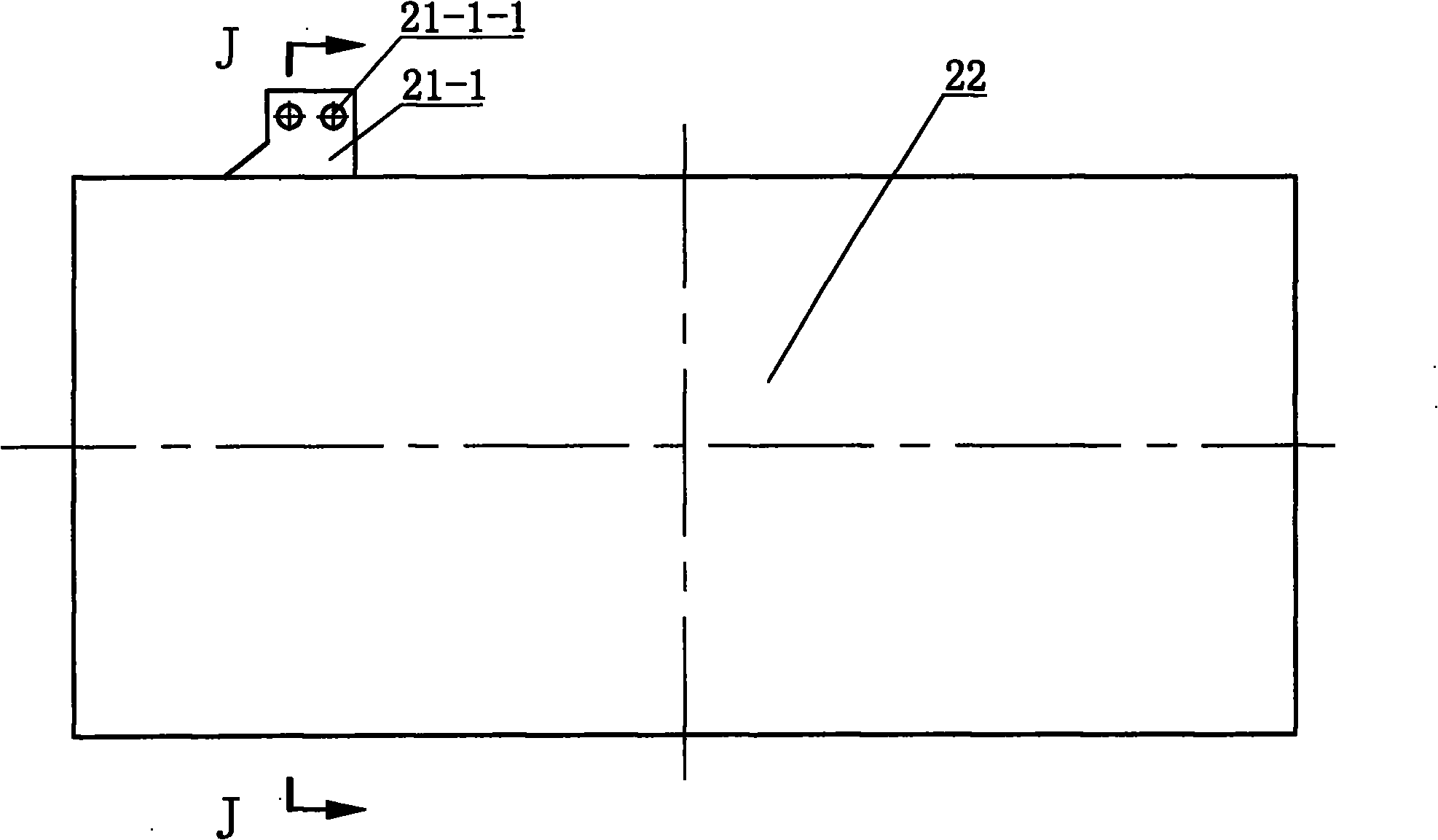

[0047] like Figure 4 and Figure 8 As shown, in a negative electrode sheet of a lithium-ion capacitor battery and its manufacturing method, the negative electrode material layer 22 is a negative electrode material layer made of lithium titanate, and the thickness of the activated carbon layer 23 is 12um.

Embodiment 3

[0049] This embodiment is basically the same as Embodiment 1. the difference is:

[0050] like Figure 9 to Figure 11 As shown, in a positive electrode sheet of a lithium-ion capacitor battery and its manufacturing method, the positive electrode material layer 12 is a positive electrode material layer made of lithium cobaltate material, and the thickness of the activated carbon layer 13 is 15um.

[0051] like Figure 4 and Figure 8 As shown, in a negative electrode sheet of a lithium-ion capacitor battery and its manufacturing method, the negative electrode material layer 22 is still a negative electrode material layer made of graphite, and the thickness of the activated carbon layer 23 is 15um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com