Preparation method of multiple-duct composite metal oxide

A composite metal and oxide technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the nutritional value, water retention and adsorption performance of artemia eggshells, multi-level pore structure Research and structure replication have not been reported, and the periodicity of the pore structure is not strong, etc., to achieve the effect of wide application value, shortened distance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

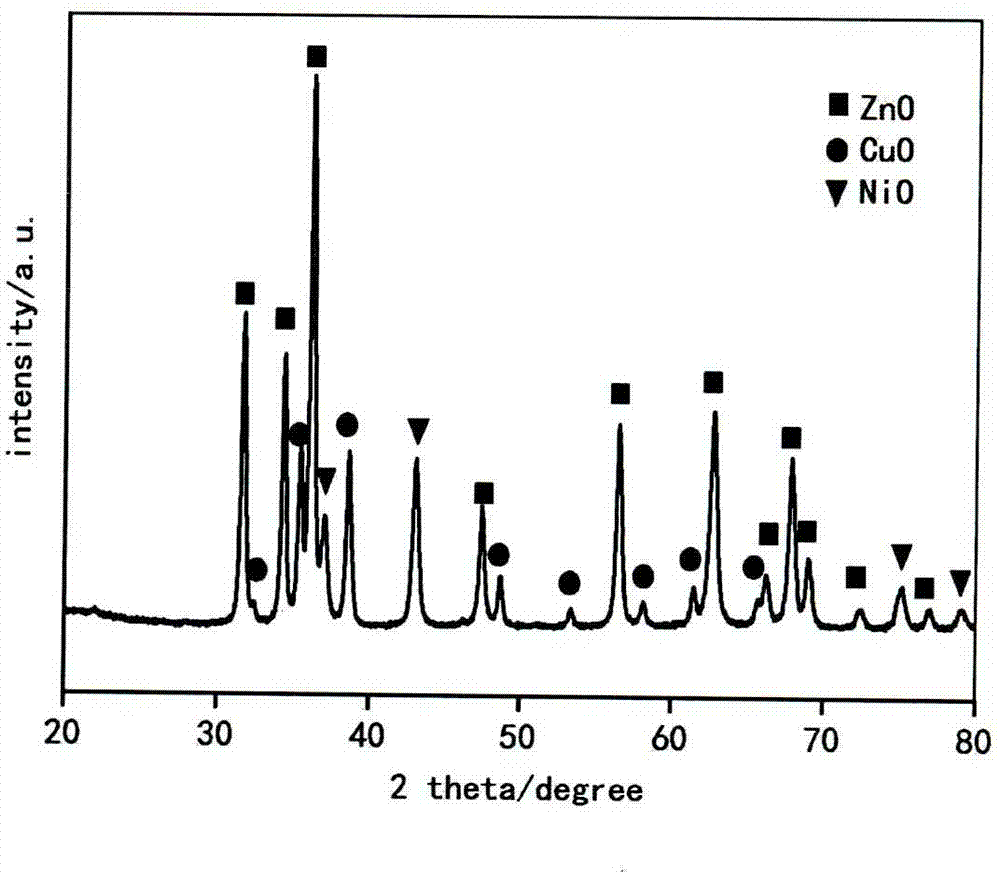

[0020] Dissolve 1.26g Pluronic F127 in 100ml water, stir for 0.5h at 400r / min at 40℃, add 0.1g lithium acetate, 1g nickel nitrate, 1g copper nitrate and 2g zinc nitrate to the above solution, continue to stir at constant temperature for 1h; Wash Artemia egg shells, and after ball milling for 6 hours, use 6mol / L HCl and 8mol / L H 2 SO 4 , 6mol / L HNO 3 , 2mol / L KOH soaking pretreatment, soaking time is 2h for each substance, drying to remove water. Add 7.4263g of citric acid and 0.5g of Artemia egg shell to the above-mentioned solution of adding metal salt, continue to stir to form a sol, adjust the Ph value to 6 with ammonia water, raise the temperature to 80°C, and stir until a gel is formed. The obtained gel was dried in an oven at 80°C for 6 hours to form a dry gel. Then, the obtained dry gel is heated at a temperature of 1°C / min, the calcination temperature is controlled to 500°C, and the temperature is kept for 4 hours, to obtain a multi-stage pore LiNiCuZn composite metal o...

Embodiment 2

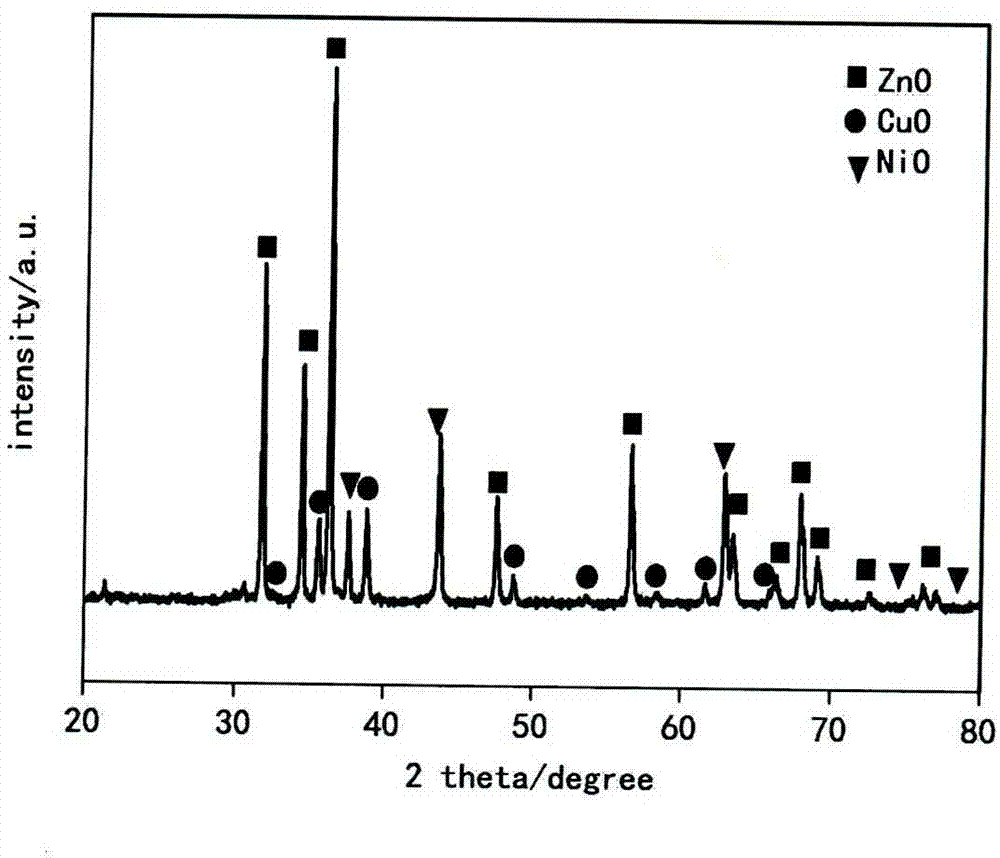

[0022] 0.5285g CTAB was mixed in 100ml water and stirred at a speed of 600r / min for 0.75h at 50°C. Add 3.05g of lithium acetate, 4g of nickel acetate, 4.5g of copper nitrate, 8g of zinc nitrate to the above solution, and stir for 1.5h at constant temperature; clean the artemia egg shells, and after ball milling for 6 hours, use 9mol / L HCl respectively , 13mol / L of H 2 SO 4 , 10mol / L HNO 3 , 4mol / L KOH soaking pretreatment, soaking time is 4h for each substance, drying to remove water. Add 31.8517g of citric acid and 2.35g of Artemia egg shells to the above-mentioned solution of adding metal salt, continue to stir to form a sol, adjust the Ph value to 7 with ammonia water, raise the temperature to 90°C, and stir until a gel is formed. The obtained gel was placed in an oven at 90° C. and dried for 15 hours to form a dry gel. Then, the obtained dry gel is heated at a rate of 6°C / min, the calcination temperature is controlled to 600°C, and the temperature is kept for 5 hours, then...

Embodiment 3

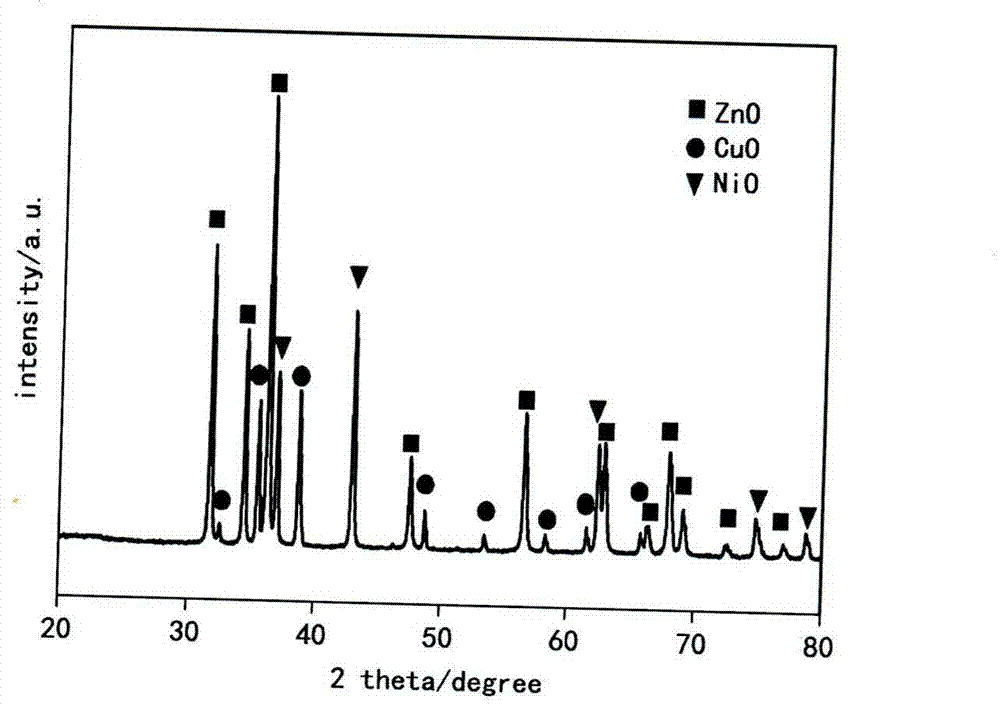

[0024] 1.093g CTAB was dissolved in 100ml water and stirred at 60°C at a speed of 800r / min for 1h. Add 6g of lithium nitrate, 7g of nickel acetate, 8g of copper acetate and 14g of zinc acetate to the above solution, continue to stir at constant temperature for 2h; clean the Artemia egg shells, and after ball milling for 6 hours, use 12mol / L HCl and 18mol respectively / L of H 2 SO 4 , 14mol / L HNO 3 , 6mol / L KOH soaking pretreatment, soaking time is 6h for each substance, drying to remove water. Add 46.0227g of citric acid and 5g of Artemia egg shells to the above-mentioned solution of adding metal salt, continue to stir to form a sol, adjust the Ph value to 8 with ammonia water, raise the temperature to 100°C, and stir until a gel is formed. The obtained gel was placed in an oven at 100° C. and dried for 24 hours to form a dry gel. Then, the obtained dry gel is heated at a rate of 10°C / min, the calcination temperature is controlled to 800°C, and the temperature is kept for 6 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com